55

Step 3 — Make Electrical Connections — Refer

to unit nameplate for required supply voltage, fan and heater

amperage and required circuit ampacity. Refer to unit wire dia-

gram for unit and field wiring. Make sure all electrical connec-

tions are in accordance with unit wiring diagram and all appli-

cable codes.

The fan motor(s) should never be controlled by any wiring

or device other than the factory-supplied switch or thermostat/

switch combination unless prior factory authorization is

obtained. Fan motor(s) may be temporarily wired for use

during construction only with prior factory approval and only

in strict accordance with the instructions issued at that time.

Floor cabinet type units have factory-wired integral fan

switches. Connect power wires to leads in unit junction box per

unit wiring diagram. On the other units, install remote fan

switch according to job drawings. Hook up switch and power

wiring per unit wiring diagram.

Install optional, wall-mounted thermostat per instructions

shipped with thermostat. Connect as shown on unit wiring

diagram.

Units with factory-supplied and factory-installed aquastats

may be shipped with the aquastats mounted on a coil stub-out.

If this is the case, remove the aquastat before installing valve

package. When reinstalling aquastats, consult the factory-

piping diagram in the submittal for proper location. If the valve

package is field-supplied, the aquastat must be installed in a

location where it will sense the water temperature regardless of

the control valve position. A bleed bypass may be required to

guarantee proper aquastat operation. The aquastat bypass line

allows a small amount of water to flow from the supply to the

return piping when the control valve is closed.

NOTE: The aquastat must be able to sense whether the

flowing water is being chilled or heated and switches a contact

closed to provide automatic summer or winter changeover for

the system. When a two-pipe cooling/heating system with

optional auxiliary electric heat is desired, an additional

aquastat is required.

All field wiring must be in accordance with governing

codes and ordinances. Any modification of unit wiring without

factory authorization will invalidate all factory warranties and

nullify any agency listings.

Units may be equipped with line voltage controls or

24 VAC control systems. The following descriptions are for

line voltage controls only. For 24 v control operating sequence,

refer to thermostat operating instructions.

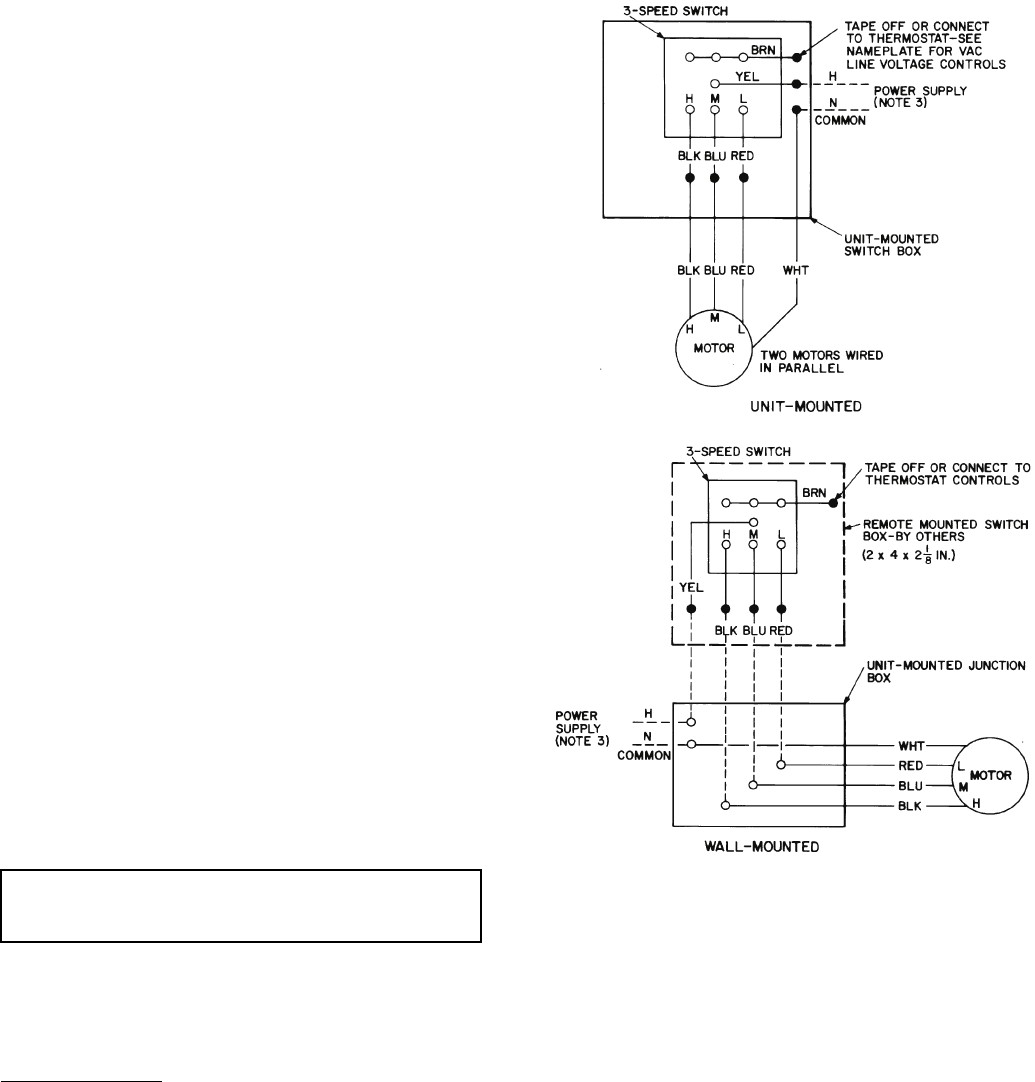

STANDARD WIRING PACKAGES

M

anual Fan Control — On all vertical cabinet units, the stan-

dard fan-speed switch is furnished unit-mounted and wired.

See Fig. 50. On all vertical furred-in units and all horizontal

units, the switch is shipped separately on a decorative wall

plate for field mounting and wiring.

The standard switch has LOW, MEDIUM, HIGH and OFF

positions plus an auxiliary contact to energize thermostats,

valves, dampers, etc.

NOTE: Wiring diagrams are for 120-v power supply. If other

voltages for heaters or controls are specified, wiring may differ

from that shown.

IMPORTANT: Wiring diagrams shown depict typical

control functions. Refer to unit wiring label for specific

functions.

Fig. 50 — Manual Fan Control

NOTES:

1. Motors are thermally protected.

2. Use copper conductors only.

3. See unit nameplate for power supply. Provided disconnect

means and overload protection as required.

4. Unit-mounted thermostats are not recommended for fan control

because of poor temperature sensing. Fan control not available

on 42VC,VE lowboy units.