41

42S UNITS — A factory tag is on top of each unit. Tag states

riser tier number, floor, room number if furnished and supply-

air arrangement. Check unit for any other labels that apply to

installation. Remove unit from pallet and take directly to

assigned space for installation. Great care must be taken to

assure that no force or pressure be applied to the coil, risers or

piping during handling. Never use the riser to lift the unit. To

maintain the straight and square cabinet alignment, avoid lift-

ing or supporting the cabinet only at the top and bottom.

1. Begin on lowest floor and progress upward, floor by

floor, to top.

2. Examine drain line (Fig. 28-34). Be sure both ends are in

place and that it forms a trap. Avoid pinching drain line.

3. Tip unit over riser hole in building floor. As unit is

righted, align riser with unit below.

NOTE: The unit must be lowered into the space taking

care to properly align the risers to engage the riser swaged

section on the unit below. The riser should never be bent

or pushed together to be passed through the floor slot and

should never be lifted up or pulled down to meet the riser

on the floor below or above.

4. Install isolator pads beneath the four corners of unit if

applicable.

5. Before anchoring the equipment in place, the unit must be

leveled and the cabinet must be squared and brought into

line with any adjacent or included walls. The unit may be

anchored in place by bolting directly through the unit

floor or attaching to the cabinet in some location that will

not interfere with drywall or other items such as the sup-

ply grille, thermostat, or return access panel. When at-

taching to the unit cabinet, care must be taken to not pen-

etrate the cabinet in locations that may damage internal

components or wiring. The mounting technique is a mat-

ter of choice; however, the unit should always be an-

chored securely to prevent movement during construction

and riser expansion and contraction. On certain units,

shipping screws or braces must be removed after the unit

is installed. Be sure to check all tags on the unit to deter-

mine which, if any, of these devices need to be removed.

6. If installing a 42SJ unit, follow Steps a-h. For all other

42S units, continue to Step 7.

NOTE: The 42SJ back-to-back fan coils have been de-

signed to serve two separate rooms. These products are

classified by Underwriters Laboratories Inc. for use in

penetration firestop systems, control number 27WL when

ordered with 1-hr rated chase. See UL Fire Resistance

Directory for more information. Figure 37 shows the

42SJ unit with standard risers and with Siamese risers.

a. Lay out the control lines for the drywall track and

studs in the floor and ceiling (see Fig. 38).

NOTE: Tracking may be installed now or after the

unit is set.

b. Position the 42SJ fan coil assembly between two

rooms with the unit drywall separation spotted

over the wall control lines.

c. If not already installed, install the floor and ceiling

tracks up to and over the 42SJ fan coil unit.

d. Position the vertical studs and fasten into each of

the stud pockets formed into the chase side panels

(see Fig. 38).

NOTE: The studs may be mechanically fastened

to the 42SJ fan coil. Care should be taken, how-

ever, not to penetrate the supply or return water

risers or internal piping. Given the levelness of the

floor and/or the fan coil assembly, some shimming

may be necessary.

e. Assemble the specified wall construction up to

and over the top of the fan coil unit (see Fig. 39).

f. With the fire-wall separation being complete, the

drywall skin on the surface of the individual fan

coils can be applied. Drywall can be applied

directly to the surface, or, if necessary, studding

may be installed on the corners for vertical control

(see Fig. 39).

g. For ease of installation of the access panel, apply

drywall on the return air side directly to the sur-

face of the unit (see Fig. 39). When applying the

wall board directly to the unit cabinet, it may be

necessary to shim the wall board in some areas to

achieve the desired finished wall surface.

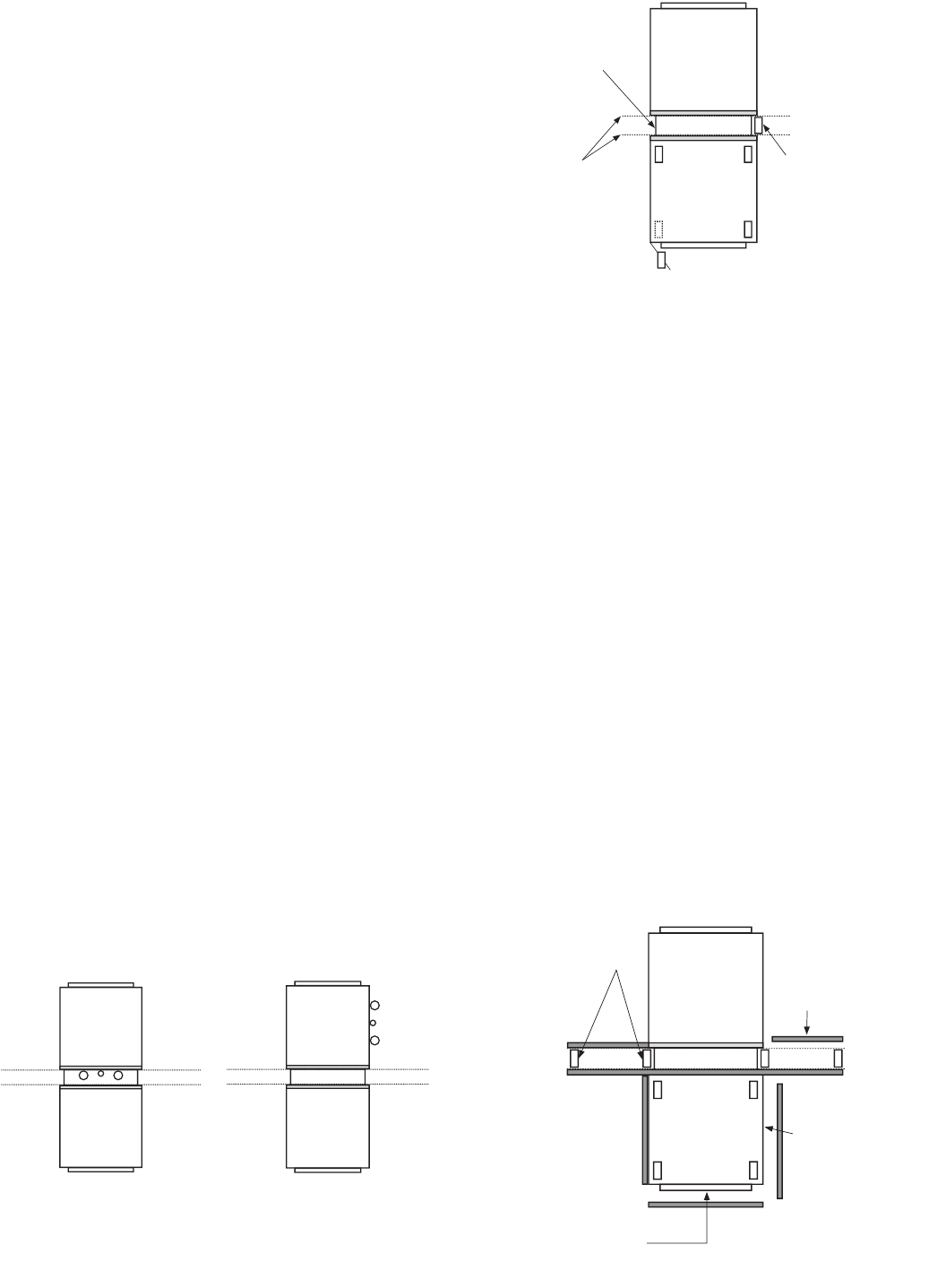

42SJB

42SJA

42SJB

42SJA

Fig. 37 — 42SJ Unit with Standard and Siamese

Risers

INSTALL WALL

STUD INTO

POCKET

FORMED BY

CHASE SIDE

PANEL

CHASE

SIDE

PANEL

DRYWALL

TRACK AND

STUD

CONTROL

LINES

INSTALL STUDS FROM TOP OF

UNIT TO CEILING (4 CORNERS)

Fig. 38 — 42SJ Unit as Shipped

WALL STUDS

INSTALL WALL

GYPSUM

BOARD

(TO WALL AND

OVER TOP OF

UNIT)

INSTALL

GYPSUM

BOARD TO

UNIT SIDES

INSTALL

GYPSUM

BOARD TO

FACE OF

UNIT WITH

CUT OUTS

FOR SUPPLY,

RETURN AND

THERMOSTAT

Fig. 39 — 42SJ Unit Installation