51

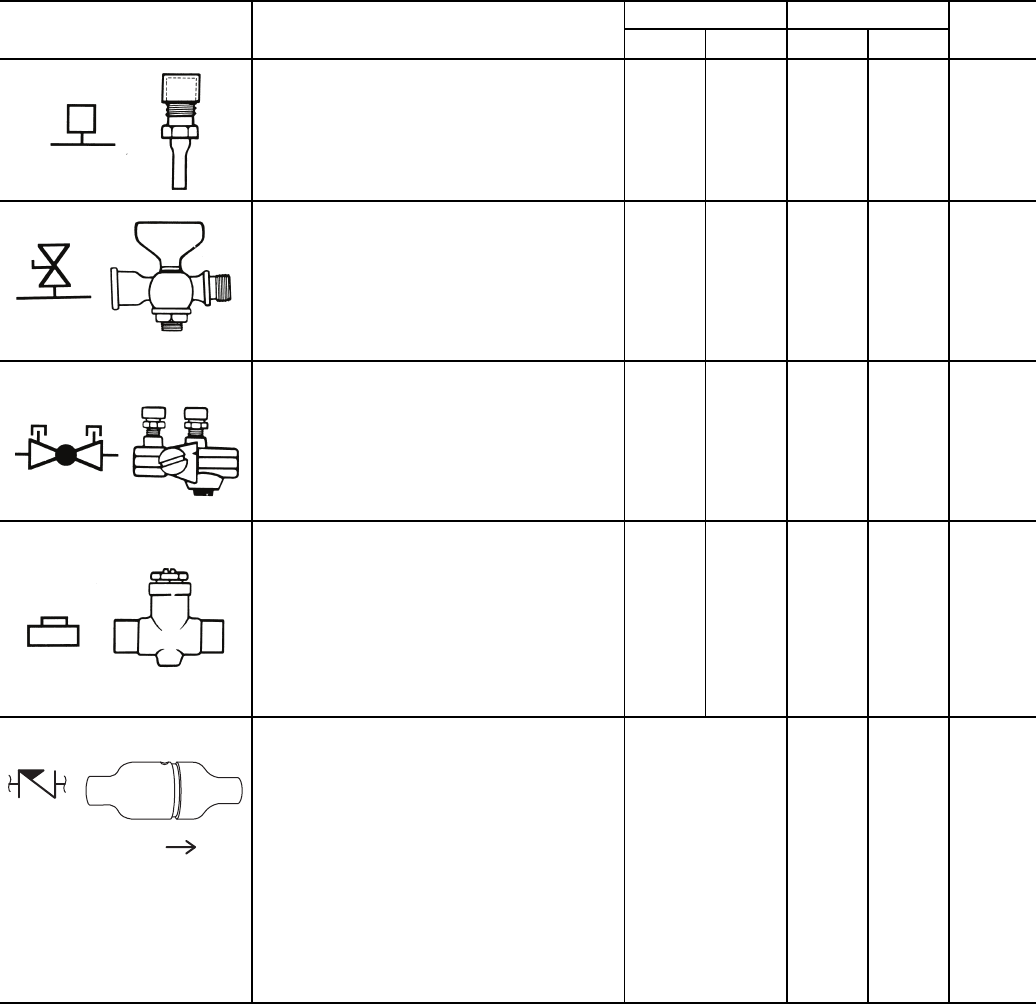

Table 5 — Piping Components (cont)

LEGEND

*Check all system component pressure ratings (coils, values,

pumps, etc.) with manufacturer and any applicable local or national

piping codes prior to specifying system pressure rating.

NOTES:

1. Motorized 2-way valves have a maximum close-off differential

of 25 psi.

2. Motorized 3-way valves have a maximum close-off differential

of 10 psi.

SYMBOL/SKETCH DESCRIPTION

C

V

FACTOR RATING*

STEAM

USE

1

/

2

in.

3

/

4

in. PSI F

PRESSURE TEST PORT: Brass body

1

/

4

in.

service access fitting with removable depres-

sor type core.

Application — Installed on both sides of the

coil to allow for pressure sensing. Attach

pressure gages to facilitate close tolerance

water balancing.

N/A N/A 400 210 NO

GAGE COCK: Brass shut-off valve with

1

/

4

in. FPT fitting for attachment of pressure

gages.

Application — Installed on both sides of the

coil to allow for pressure sensing. Attach

pressure gages to facilitate close tolerance

water balancing. May be used in bleed

bypass line to regulate water flow.

N/A N/A 200 250 N/A

CIRCUIT SETTER: Variable water flow bal-

ancing valve with manual adjustment knob,

pointer, percent-open scale, memory stop

and integral pressure read-out ports.

Application — Used for close tolerance water

flow balancing. Positive shut-off ball valve

feature allows usage as combination balanc-

ing and shut-off valve.

2.12 3.9 300 250 NO

BALANCE VALVE: Variable water flow man-

ual balancing valve with screwdriver slot

adjustment screw.

Application — Often used in conjunction with

test port fittings for water flow balancing. Bal-

ance by temperature differential or coil pres-

sure drop (check specifications for service

fittings required if balancing by pressure

drop). May be used in 3-way valve bypass

line to permit equal flow balancing.

3.0 8.9 150 200 NO

FIXED FLOW VALVE: Flexible orifice type

(non-adjustable).

Application — Used for water flow balancing.

Valve automatically adjusts the flow to within

10% of set point. Requires 15 psi

(35 ft) of additional pump head for proper

operation.

Valve orifice size

determines C

V

fac-

tor. The orifice of

these fixed flow

valves changes as

flow is regulated.

As the water pres-

sure increases,

the orifice size

decreases,

thereby automati-

cally limiting the

flow rate to the

specified gpm

(±10%).

150 160 NO

FLOW

Cv — Coefficient of Velocity

DX — Direct Expansion