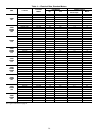

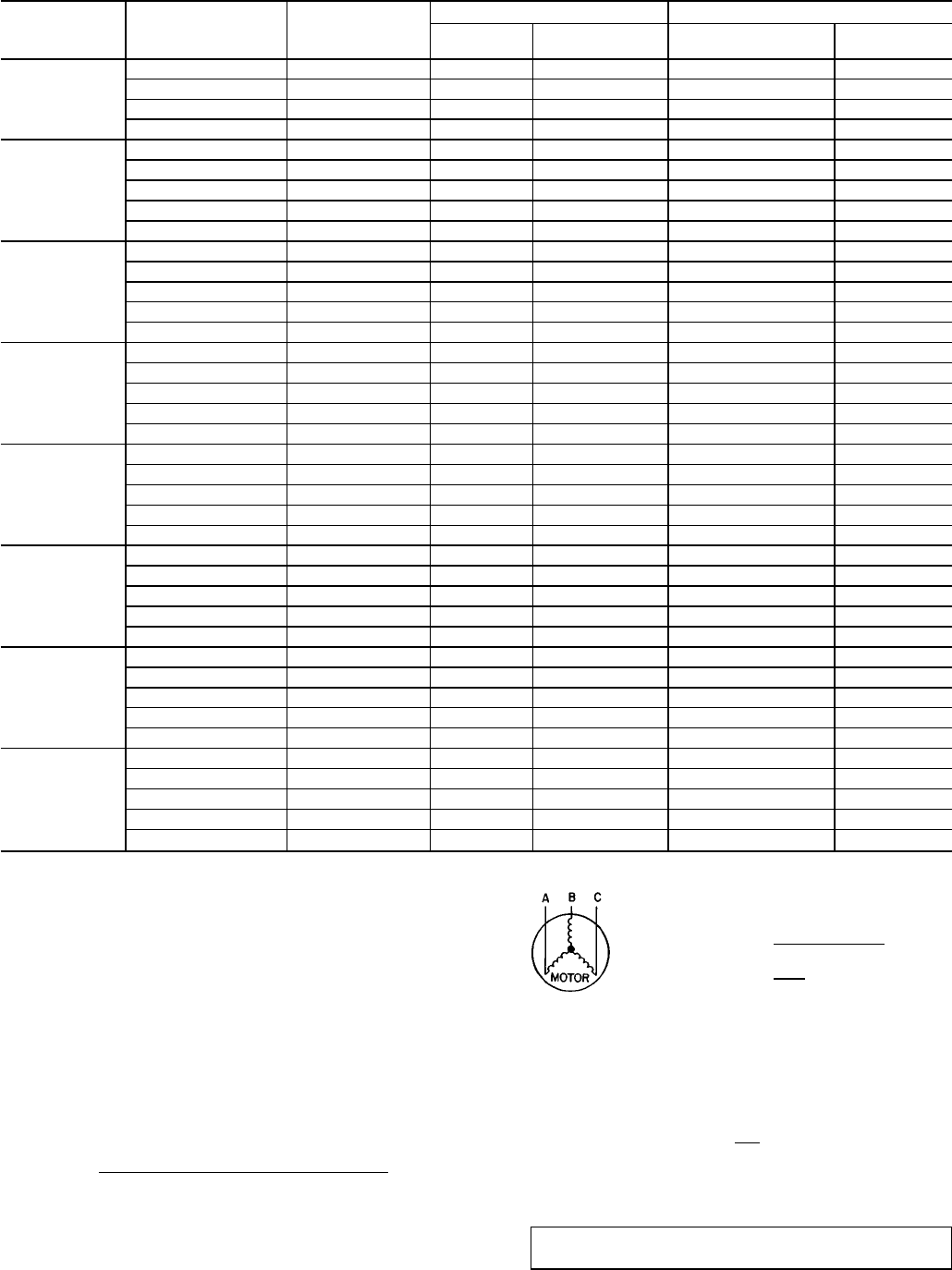

Table 5 — Electrical Data, Alternate Motors

UNIT V*-PH-HZ

VOLTAGE

LIMITS

FAN MOTOR POWER SUPPLY

Hp FLA

Minimum

Circuit Amps

MOCP

40RM

007

208/230-1-60 187-253 2.4 11.0 13.8 20

208/230-3-60 187-253 2.9 7.5 9.4 15

460-3-60 414-528 2.9 3.4 4.3 15

575-3-60 518-632 2.0 2.4 3.0 15

40RM

40RMQ

40RMS

008

208/230-3-60 187-253 2.9 7.5 9.4 15

460-3-60 414-528 2.9 3.4 4.3 15

575-3-60 518-632 3.0 3.8 4.8 15

230-3-50 207-253 2.9 7.5 9.4 15

400-3-50 360-440 2.9 3.4 4.3 15

40RMS

010

208/230-3-60 187-253 2.9 7.5 9.4 15

460-3-60 414-528 2.9 3.4 4.3 15

575-3-60 518-632 3.0 3.8 4.8 15

230-3-50 207-253 2.9 7.5 9.4 15

400-3-50 360-440 2.9 3.4 4.3 15

40RM

40RMQ

40RMS

012

208/230-3-60 187-253 3.7 10.6 13.3 20

460-3-60 414-528 3.7 4.8 6.0 15

575-3-60 518-632 3.0 3.8 4.8 15

230-3-50 207-253 5.0 14.4 18.0 30

400-3-50 360-440 5.0 7.2 9.0 15

40RM

40RMS

014

208/230-3-60 187-253 3.7 10.6 13.3 20

460-3-60 414-528 3.7 4.8 6.0 15

575-3-60 518-632 5.0 5.6 7.0 15

230-3-50 207-253 5.0 14.4 18.0 30

400-3-50 360-440 5.0 7.2 9.0 15

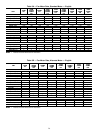

40RM

40RMQ

40RMS

016

208/230-3-60 187-253 5.0 15.2/14.4 19.9/18.0 30/30

460-3-60 414-528 5.0 7.2 9.0 15

575-3-60 518-632 5.0 5.6 7.0 15

230-3-50 207-253 5.0 14.4 18.0 30

400-3-50 360-440 5.0 7.2 9.0 15

40RM

40RMS

024

208/230-3-60 187-253 7.5 22.0/21.0 27.5/26.3 45/45

460-3-60 414-528 7.5 10.5 13.1 20

575-3-60 518-632 7.5 7.6 9.5 15

230-3-50 207-253 7.5 21.0 26.3 45

400-3-50 360-440 7.5 10.5 13.1 20

40RM

40RMS

028

208/230-3-60 187-253 10.0 26.4/25.0 33.0/31.3 55/55

460-3-60 414-528 10.0 12.5 15.6 25

575-3-60 518-632 10.0 9.6 12.0 20

230-3-50 207-253 10.0 25.0 31.3 55

400-3-50 360-440 10.0 12.5 15.6 25

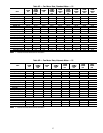

LEGEND

FLA — Full Load Amps

MOCP — Maximum Overcurrent Protection

*Motors are designed for satisfactory operation within 10% of nomi-

nal voltages shown. Voltages should not exceed the limits shown in

the Voltage Limits column.

NOTES:

1. Minimum Circuit Amp and MOCP values are calculated in

accordance with NEC (National Electrical Code) (U.S.A. stand-

ard), Article 440.

2. Motor FLA values are established in accordance with UL (Under-

writers’ Laboratories) Standard 1995 (U.S.A. standard).

3. Unbalanced 3-Phase Supply Voltage

Never operate a motor where a phase imbalance in supply volt-

age is greater than 2%.

Use the following formula to determine

the percentage of voltage imbalance.

% Voltage Imbalance

max voltage deviation from average voltage

= 100 x

average voltage

EXAMPLE: Supply voltage is 400-3-50.

AB = 393 v

BC = 403 v

AC = 396 v

393 + 403 + 396

Average Voltage =

3

1192

=

3

= 397

Determine maximum deviation from average voltage.

(AB) 397 − 393 = 4 v

(BC) 403 − 397 = 6 v

(AC) 397 − 396 = 1 v

Maximum deviation is 6 v.

Determine percent voltage imbalance.

6

% Voltage Imbalance = 100 x

397

= 1.5%

This amount of phase imbalance is satisfactory as it is below the

maximum allowable 2%.

IMPORTANT: If the supply voltagephase imbalance is more than

2%, contact your local electric utility company immediately.

21