OUTDOOR UNIT CONNECTED TO FACTORY APPROVED

INDOOR UNIT

Outdoor unit contains correct system refrigerant charge for opera-

tion with indoor unit of same size when connected by 15 ft of

field-supplied or factory accessory tubing. Check refrigerant

charge for maximum efficiency.

REFRIGERANT TUBING

Connect tubing to fittings on outdoor unit vapor- and liquid-

service valves. (See Table 1.) Use refrigerant grade tubing.

SWEAT CONNECTION

To avoid valve damage while brazing, service valves must be

wrapped in a heat sink material such as a wet cloth.

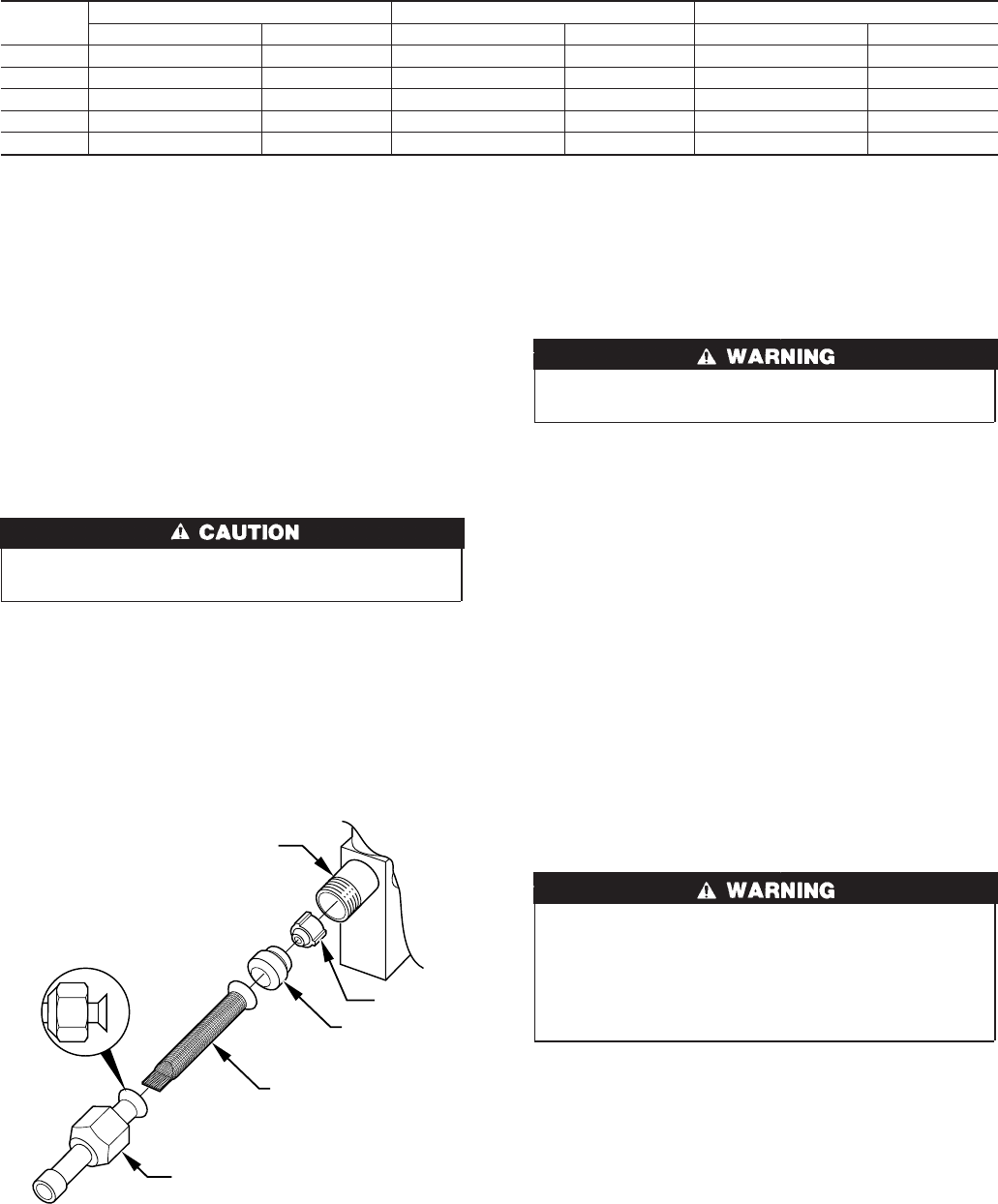

Remove plastic retainer holding outdoor piston in liquid service

valve and connect sweat/flare adapter provided to valve. (See Fig.

7.) Connect refrigerant tubing to fittings on outdoor unit vapor-

and liquid-service valves. Service valves are closed from factory

and ready for brazing. After wrapping service valve with a wet

cloth, tubing set can be brazed to service valve using either silver

bearing or non-silver bearing brazing material. Consult local code

requirements. Refrigerant tubing and indoor coil are now ready for

leak testing. This check should include all field and factory joints.

IMPORTANT: Check to be certain factory tubing on both indoor

and outdoor unit has not shifted during shipment. Ensure tubes are

not rubbing against each other or any sheet metal. Pay close

attention to feeder tubes, making sure wire ties on feeder tubes are

secure and tight.

Step 10—Make Electrical Connections

To avoid personal injury or death, do not supply power to unit

with compressor terminal box cover removed.

Be sure field wiring complies with local and national fire, safety,

and electrical codes, and voltage to system is within limits shown

on unit rating plate. Contact local power company for correction of

improper voltage. See unit rating plate for recommended circuit-

protection device.

NOTE: Operation of unit on improper line voltage constitutes

abuse and could affect unit reliability. See unit rating plate. Do not

install unit in system where voltage may fluctuate above or below

permissible limits.

NOTE: Use copper wire only between disconnect switch and

unit.

NOTE: Install branch circuit disconnect of adequate size per

NEC to handle unit starting current. Locate disconnect within sight

from and readily accessible from unit, per Section 440-14 of NEC.

ROUTE GROUND AND POWER WIRES

Remove access panel to gain access to unit wiring. Extend wires

from disconnect through power wiring hole provided and into unit

control box.

The unit cabinet must have an uninterrupted or unbroken

ground to minimize personal injury if an electrical fault

should occur. The ground may consist of electrical wire or

metal conduit when installed in accordance with existing

electrical codes. Failure to follow this warning can result in an

electric shock, fire, or death.

CONNECT GROUND AND POWER WIRES

Connect ground wire to ground connection in control box for

safety. Connect power wiring to contactor as shown in Fig. 8.

CONNECT CONTROL WIRING

Route 24v control wires through control wiring grommet and

connect leads to control wiring. See Thermostat Installation

Instructions for wiring specific unit combinations. (See Fig. 9.)

Use No. 18 AWG color coded, insulated (35°C minimum) wire. If

thermostat is located more than 100 ft from unit, as measured

along the control voltage wires, use No. 16 AWG color coded wire

to avoid excessive voltage drop.

All wiring must be NEC Class 1 and must be separated from

incoming power leads.

Table 1—Refrigerant Connections And Recommended Liquid- And Vapor-Tube Diameters (In.)

UNIT

SIZE

LIQUID VAPOR VAPOR (LONG LINE)

Connection Diameter Tube Diameter Connection Diameter Tube Diameter Connection Diameter Tube Diameter

018 3/8 3/8 5/8 5/8 5/8 3/4

024 3/8 3/8 3/4 3/4 3/4 3/4

030, 036 3/8 3/8 3/4 3/4 3/4 7/8

042 3/8 3/8 7/8 7/8 7/8 1-1/8

048, 060 3/8 3/8 7/8 1-1/8 7/8 1-1/8

NOTES:

1. Tube diameters are for lengths up to 50 ft. For tubing lengths greater than 50 ft horizontal, or greater than 20 ft vertical differential, consult the Application Guideline

and Service Manual — Air Conditioners and Heat Pumps.

2. Do not apply capillary tube indoor coils to these units.

Fig. 7—Liquid-Service Valve

A97512

PISTON BODY

PISTON

PISTON

RETAINER

SWEAT/FLARE ADAPTER

STRAINER

4