START-UP

Preliminary Checks

1. Check that all internal wiring connections are tight and

that all barriers, covers, and panels are in place.

2. Field electrical power source must agree with unit name-

plate rating.

3. Ensure all service valves are open. Ensure all compressor

service valves are backseated.

4. Verify that compressor holddown bolts have been loos-

ened and that flat/snubber washers can be rotated by fin-

ger pressure (snug, but not tight).

5. Verify compressor crankcase heater is securely in place.

Crankcase heater must operate for at least 24 hours be-

fore start-up.

6. Note that compressor oil level is visible in the sight glass.

7. Check for leaks in refrigerant system by using soap bubbles

and/or electronic leak detector.

8. Check voltage imbalance as shown in Table 4, Note 2.

9. Check that both outdoor and indoor units are properly

mounted in accordance with installation instructions and

applicable codes.

Evacuate and Dehydrate — Evacuate and dehydrate

entire refrigerant system by use of the methods

described in Carrier GTAC II, Module 4, System

Dehydration.

Refrigerant Charge — Refer to Carrier GTAC II, Mod-

ule 5, Charging Recovery, Recycling, and Reclamation.

NOTE: Use of a Carrier Totalclaim refrigeration recovery

unit is highly recommended when recovering refrigerant.

Unit panels must be in place when unit is operating dur-

ing charging procedure.

Unit is shipped with holding charge only. Weigh in 15 lb

(7 kg) of R-22 to start unit.

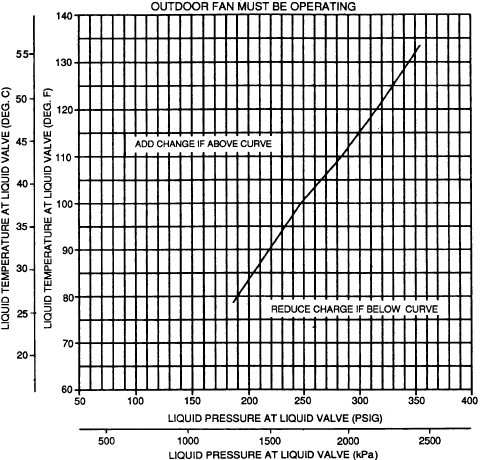

CHARGE COOLING — Use Cooling Charging Chart (see

Fig. 11). Vary refrigerant until the conditions of the chart are

met. Note that charging chart is different from the type nor-

mally used. Chart is based on charging the units to the cor-

rect subcooling for the various operating conditions. Accu-

rate pressure gage and temperature sensing device are required.

Connect the pressure gage to the service port on the liquid

line service valve. Mount the temperature sensing device on

the liquid line, close to the liquid line service valve, and in-

sulate it so that outdoor ambient temperature does not affect

the reading. Indoor airflow must be within the normal op-

erating range of the unit.

Operate unit a minimum of 15 minutes. Ensure pressure

and temperature readings have stabilized. Plot liquid pres-

sure and temperature on chart and add or reduce charge to

meet curve. Adjust charge to conform with charging chart,

using liquid pressure and temperature to read chart.

OIL CHARGE (Tables 1A and 1B) — Allow unit to run for

about 20 minutes. Stop unit and check compressor oil level.

Add oil only if necessary to bring oil into view in sight glass.

Use only Carrier-approved compressor oil.

Approved oils are:

Suniso 3GS and WF32-150

Do not reuse drained oil or use any oil that has been ex-

posed to atmosphere. Procedures for adding or removing oil

are given in Carrier’s Refrigerant Service Techniques manual.

If oil is added, run unit for additional 10 minutes. Stop

unit and check oil level. If level is still low, add oil only after

determining that piping system is designed for proper oil re-

turn and that system is not leaking oil.

Refrigerant Service Ports — Each unit system has 3

service ports: one on the suction line, one on the liquid line,

and one on the compressor discharge line. Be sure caps on

the ports are tight.

Sequence of Operation — When power is supplied

to unit, the transformer (TRAN) is energized. The crankcase

heater is also energized.

COOLING — With the thermostat subbase in the cooling

position, and when the space temperature comes within

2° F (1° C) of the cooling set point, the thermostat makes

circuit R-O. This energizes the reversing valve solenoid (RVS)

and places the unit in standby condition for cooling.

As the space temperature continues to rise, the second stage

of the thermostat makes, closing circuit R-Y. When com-

pressor time delay (5 ± 2 minutes) is completed, a circuit is

made to contactor (C ), starting the compressor (COMP) and

outdoor-fan motor (OFM). Circuit R-G is made at the same

time, energizing the indoor-fan contactor (IFC) and starting

the indoor-fan motor (IFM) after one-second delay.

When the thermostat is satisfied, contacts open, deener-

gizing C. The COMP, IFM, and OFM stop.

HEATING — On a call for heat, thermostat makes circuits

R-Y and R-G. When compressor time delay (5 ± 2 minutes)

is completed, a circuit is made to C, starting COMP and OFM.

Circuit R-G also energizes IFC and starts IFM after a 1-second

delay.

Fig. 11 — Cooling Charging Chart — 38AQS008

10