PRE-START-UP

Evacuate and Dehydrate

the entire refrigerant sys-

tem by either of the methods described in Carrier Standard

Service Techniques Manual, Chapter 1.

Leak Test the entire refrigerant system by the pres-

sure method described in Carrier Standard Service Tech-

niques Manual, Chapter 1. Use R-22 at approximately

25 psig (172.4 kPa) backed up with an inert gas to a total

pressure not to exceed 245 psig (1689 kPa).

Turn on Crankcase Heaters for 24 hours before start-

ing the unit to be sure all the refrigerant is out of the oil. To

energize the crankcase heaters, proceed as follows.

1. Set the space thermostat set point above the space tem-

perature so there is no demand for cooling.

2. Close the field disconnect.

3. Turn the fan circuit breaker on. Leave the compressor cir-

cuit breakers off. The crankcase heaters are now

energized.

Add Preliminary Charge to the refrigerant system ac-

cordingly to Carrier Standard Service Techniques Manual,

Chapter 1. By the liquid charging method and charging by

weight procedure, charge the units with approximately the

amounts of R-22 refrigerant shown in Table 6.

Table 6 — Charging Data (R-22)

UNIT

REFRIGERANT CHARGE - lb (kg)

CONDENSING

TEMP

DURING

CHARGING-F(C)

Required Charge

Above Clear

Sight Glass

Outdoor Unit

Total Charge

(Approx)

38AE012 3.0 (1.4) 22 (10) 125 (51.7)

38AE014 4.8 (2.2) 23 (10.5) 123 (50.6)

38AE016 3.4 (1.5) 23 (10.5) 130 (54.4)

38AKS024 3.4 (1.5) 28 (12.7) 131 (54.8)

Before Starting Unit ensure the following:

1. Compressor oil level must be at least within sight in

the compressor sight glass. Add oil if necessary (see

Tables 1A-1D and Oil Charge section).

2. Compressor holddown bolts must be snug, but not tight.

Refer to Compressor Mounting section and tag on com-

pressor foot.

3. All internal wiring connections must be tight; all barriers

and covers must be in place.

4. Electrical power source must agree with unit nameplate

rating.

5. All service valves must be open.

6. Crankcase heater must be firmly locked into the com-

pressor crankcase.

START-UP

To Start Unit —

Set thermostat set point below the space

temperature. After starting unit, there is a delay of at least 3

seconds before compressor starts.

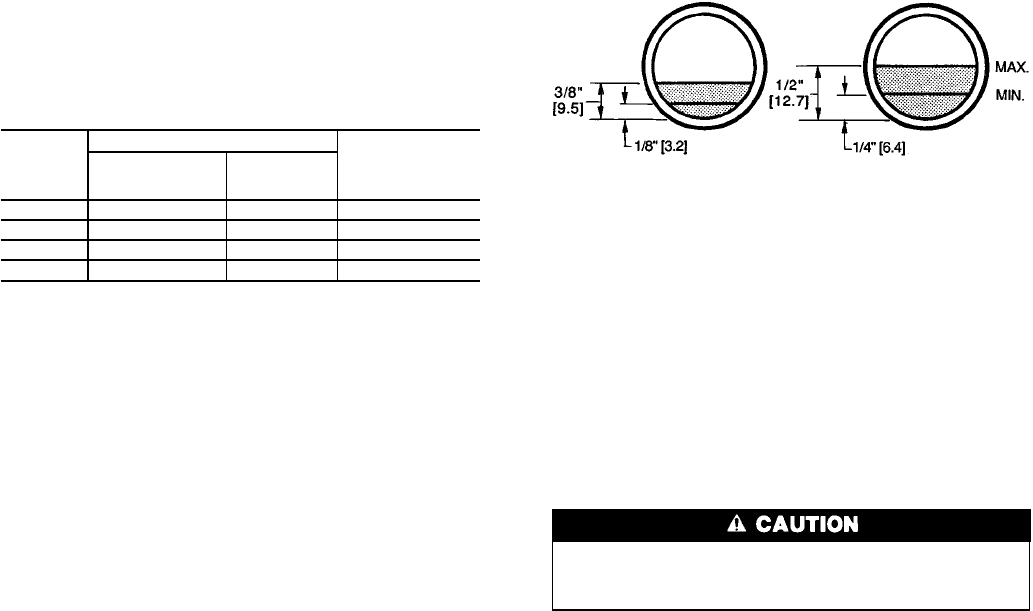

Oil Charge (see Tables 1A-1D) —Allow unit to run for

about 20 minutes. Stop unit and check compressor oil level

at sight glass. Add oil if necessary to bring oil to the correct

level shown in Fig. 8. Use only Carrier-approved compres-

sor oil. Approved oils are:

Witco Chemical Corp. ................Suniso 3GS

Texaco, Inc. ...........................WF32

Petroleum Specialties Co. ...............Cryol 150

Do not reuse drained oil or use any oil that has been ex-

posed to atmosphere. Procedures for adding or removing oil

are given in Carrier Standard Service Techniques Manual,

Chapter 1, Refrigerants.

If oil is added, run unit for additional 10 minutes. Stop

unit and check oil level. If level is still low, add oil only after

determining that piping system is designed for proper oil re-

turn and that the system is not leaking oil.

Refrigerant Charge — Actual start-up should be done

only under supervision of a qualified refrigeration me-

chanic. Refer to charging charts.

See Fig. 9-11 for the particular unit being charged. Mea-

sure pressure at the liquid line service valve, being sure a

Schrader depressor is used if required. Also, measure liquid

line temperature as close to the liquid service valve as pos-

sible. Add or reduce charge until the pressure and tempera-

ture conditions of the charging charge curve are met. If liq-

uid pressure and temperature point falls above curve, add

charge. If liquid pressure and temperature point falls below

curve, reduce the charge until the conditions match the curve.

Never charge liquid into the low-pressure side of sys-

tem. Do not overcharge. During charging or removal of

refrigerant, be sure indoor fan system is operating.

38AKS024

(06E COMPRESSOR)

38AE012,014,016

(06D COMPRESSOR)

Fig. 8 — Operating Oil Levels

9