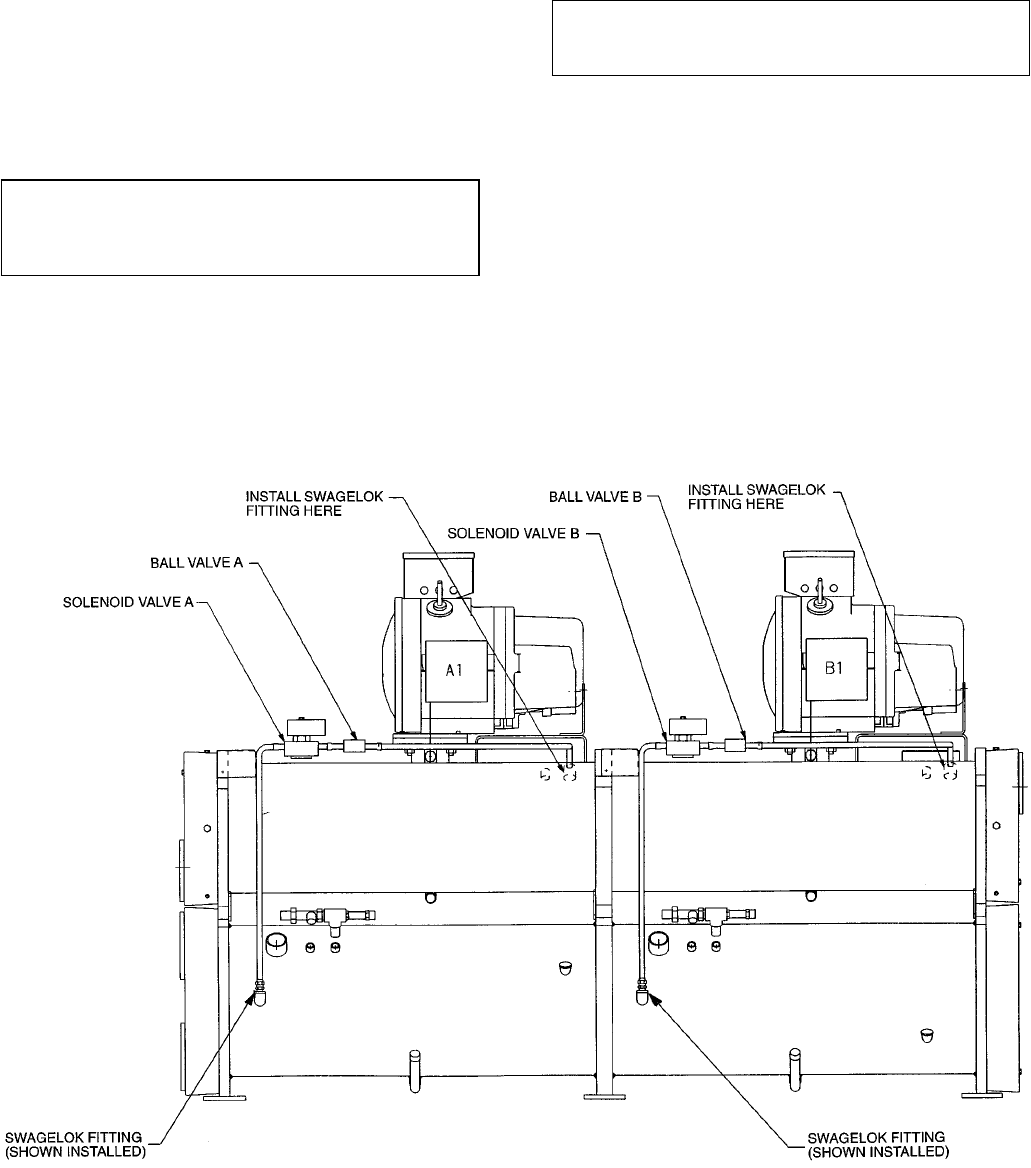

INSTALL BALLAND SOLENOIDVALVES — Using good

piping practice, braze ball valve and solenoid valve into

5

⁄

8

-in. minimum load piping. Fig. 2 shows a typical 30HX

installation and Fig. 3 shows a typical 30GX installation, in-

cluding valve locations and orientation. Ensure that ball valve

is fully open, and that both the ball and solenoid valve are

protected from excess heat during brazing process. Wrap wet

cloths around valve bodies during brazing to prevent dam-

age to the valves from heat.

IMPORTANT: When installing solenoid valve, make

sure that flow direction arrow on valve body points

towards the cooler. The minimum load control will not

function correctly if this valve is installed backwards.

CONNECT PIPING — Check the ends of the tubes where

they will be inserted into the Swagelok fittings. To avoid

leaks, tube ends must be round and free of burrs, nicks, and

grooves.

Insert tube ends into fittings as far as they will go. When

tube bottoms out, tighten the compression nut finger-tight

while holding the fitting body. Use backup wrench to hold

fitting body and tighten compression nut another 1

1

⁄

4

turns.

IMPORTANT: Do NOT overtighten the fittings. Over-

tightening the fittings can deform the tube ends and

cause leaks.

30GX UNITS ONLY — Using good brazing practice, braze

the

5

⁄

8

-in. minimum load tubing to the copper nipple on the

discharge line (minimum load port) between the condenser

coil and oil separator. See Fig. 1 and 3.

Step 3 — Dehydrate and Recharge Circuit

—

When piping has been completed, leak test the assem-

bly. If one of the Swagelok fittings leaks, slowly tighten the

compression nut until the leak stops. If this does not fix the

leak, the connection must be reinstalled using a new ferrule

and backup ring in the fitting. Contact your Carrier repre-

sentative for assistance in locating these parts.

After leak testing, evacuate, dehydrate, and recharge the

circuit using an approved refrigerant recovery device. Cor-

rect type and amount of refrigerant are listed on unit name-

plate and in base unit documentation.

Fig. 2 — Installing Fittings and Valves, 30HX (Typical)

3