Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

PC 111 Catalog No. 533-00067 Printed in U.S.A. Form 30GT/38AKS-1SI Pg 4 1-05 Replaces: 30GT-35SI

Book124

Tab 3a 5c 2a

Copyright 2005 Carrier Corporation

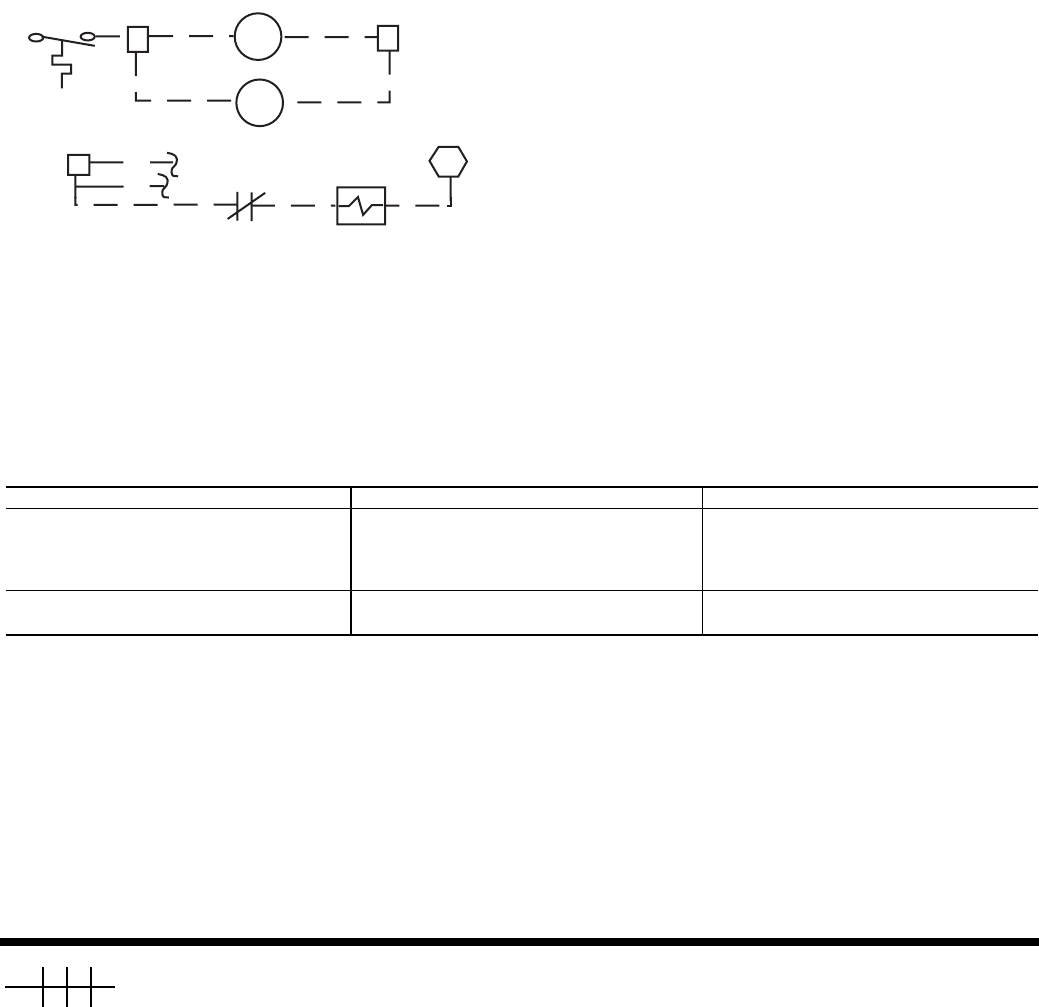

Step 2 — Install Control Wiring (See Fig. 5)

1. Install a field-supplied relay with a 24-v coil and normal-

ly closed contacts rated for 20 va at 125 vac inductive

load. Mount this relay in the 38AKS control box.

NOTE: This relay is identified in Fig. 5 as HGR (hot gas

relay).

2. For 38AKS014-024:

a. Connect a field-supplied wire between TB2-3 and

the L1 side of the HGR coil.

b. Connect a field-supplied wire between TB2-9 and

the L2 side of the HGR coil.

c. Connect a field-supplied wire between TB2-2 and

HGR-4, one of the normally closed (NC) contacts.

d. Connect one leg of the hot gas pilot solenoid valve

to HGR-6, the other NC contact.

e. Connect the other leg of the hot gas pilot solenoid

valve to C2.

Step 3 — Restore Refrigerant Charge — Charge

unit in accordance with 38AKS Charging Chart found on unit.

ACCESSORY OPERATION AND

ADJUSTMENT

Adjustment — The hot gas bypass valve is set to begin

opening when the suction pressure falls to approximately

62 psig (427 kPa). The pressure corresponds to a chilled water

set point of approximately 44 F (6 C). If the chilled water set

point is lower than 44 F (6 C), the bypass setting must be de-

creased. The opposite is true if the chilled water setting is

above 44 F (6 C).

Condensing temperature also affects the setting of the bypass

valve, and a change may be required. To adjust the setting of the

bypass valve, a

5

/

16

in. hex wrench is required. Remove the cap

on the valve, and turn the adjustment nut with the hex wrench.

Turning in a clockwise direction increases the setting, and turn-

ing in a counterclockwise direction decreases the setting.

Operation — The hot gas bypass accessory operates as fol-

lows: When a call for cooling is received, the compressor start

circuit is energized, along with the hot gas solenoid (HGS) and

all unloaders. Once the HGS circuit is completed, the solenoid

valve opens allowing the hot gas bypass valve (HGBV) to

sense suction pressure and respond accordingly.

If the suction pressure is below the HGBP (hot gas bypass)

valve setting, the valve begins to open. The valve continues to

open until it either reaches an equilibrium or the maximum

open position. Discharge gas is bypassed into the mixed-phase

line between the expansion valve and the cooler. This condition

continues until the suction pressure rises above the HGBP

valve setting, a second stage of temperature control is called

for, or the unit cycles off.

TROUBLESHOOTING

PROBLEM PROBABLE CAUSE SOLUTION

Hot Gas Bypass Valve Fails to Open. 1. Dirt or foreign material in valve.

2. Equalizer passageway clogged.

3. External equalizer not connected or

equalizer line is pinched shut.

1. Disassemble and clean valve.

2. Disassemble and clean valve.

3. Connect or replace equalizer line.

Check solenoid valve.

Hot Gas Bypass Valve Fails to Close. 1. Dirt or foreign material in valve.

2. Diaphragm failure.

1. Disassemble and clean valve.

2. Replace element only.

TC2

TB2

TB2

LLS

HGR

HGR

3

9

Hot Gas

BLU

YEL

C2

TB2

Pilot Solenoid Valve

LEGEND

NOTE: Hot Gas Relay (HGR) use Part No. HN61KK324.

HGR — Hot Gas Relay

LLS — Liquid Line Solenoid

TB — Ter m i na l B lo ck

TC — Thermostat Cooling

Fig. 5 — 38AKS014-024 Hot Gas Bypass Wiring