2

Install the field-supplied

1

/

4

in. OD tubing from the SAE

connection to the TXV equalizer line. If the connection is made

directly to the TXV, use the field-supplied, 3-way tee with an

internal branch (install horizontally in the line with the internal

branch attaching directly to the TXV). If the connection is

made into the equalizer line, use the field-supplied, standard 3-

way tee.

Step 2 — Dehydrate and Recharge the Cir-

cuit —

When piping is completed, leak test the assembly and

replace the filter drier cores. Then evacuate, dehydrate, and re-

charge the circuit, using approved refrigeration practices.

Step 3 — Install Control Wiring

Follow all local codes and NEC (National Electrical Code,

U.S.A.) when installing control wiring. All wire must be a min-

imum of 16 AWG (American Wire Gage, U.S.A.).

Connect control wires as shown in Fig. 3. At hot gas sole-

noid (HGS), connect to brown and orange wires as shown.

Be sure all power to the unit is off before proceeding, and

that all disconnects are open and tagged.

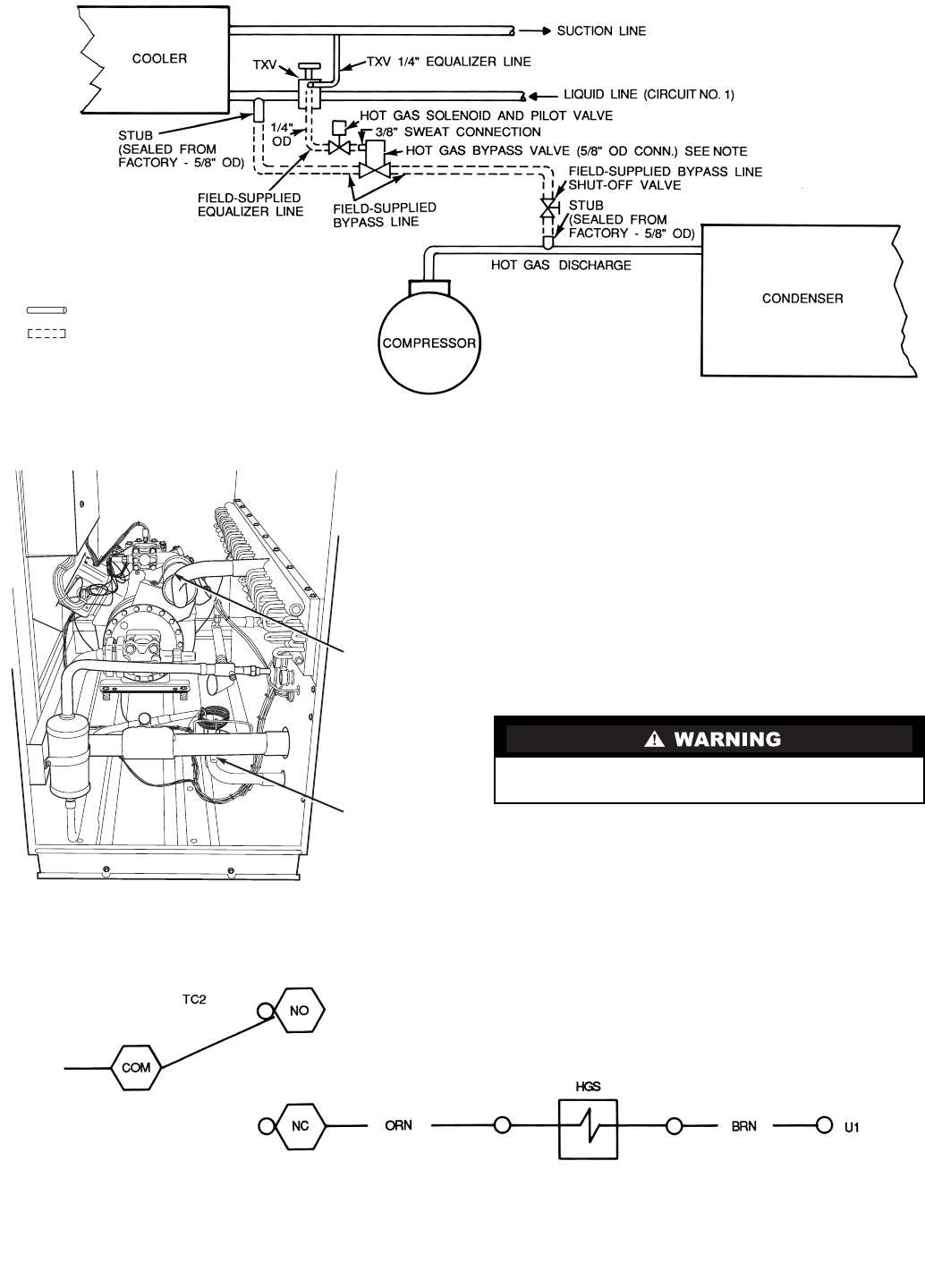

LEGEND

NOTE: The bypass valve in this package has

5

/

8

in.

connections and can be used directly on 30GT015-

035 units.

TXV — Thermostatic Expansion Valve

Factory Piping

Field Piping

Fig. 1 — 30GT Piping Schematic

DISCHARGE

STUB

(HIDDEN)

LIQUID

STUB

Fig. 2 — 30GT Stub Locations

Fig. 3 — 30GT Hot Gas Solenoid Wiring

LEGEND

COM — Common NC — Normally Closed TC — Temperature Controller

HGS — Hot Gas Solenoid NO — Normally Open U1 — Unloader 1