11

Gas connection

10. Connect incoming gas supply pipe to

1

/

2

” compression fitting at rear

of appliance. For inlet position see figure 13.

Log installation

11. The burner is contained within the burner chamber. Refer figure 14.

12. Carefully unpack the log set. Logs are numbered as follows:

No 1 - Left front log

No 2 - left back log

No 3 - Right front log

No 4 - Right back log

11 12

13

14

14

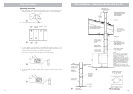

18. Switch the top two control buttons to “Full On” position as indicated in

figure 23(a) and using a ring spanner, as per figure 23(b), adjust the

pressure to 0.75 kPa for Natural gas or 2.65 kPa for LPG. (Turn clock-

wise to increase pressure and anticlockwise to decrease pressure).

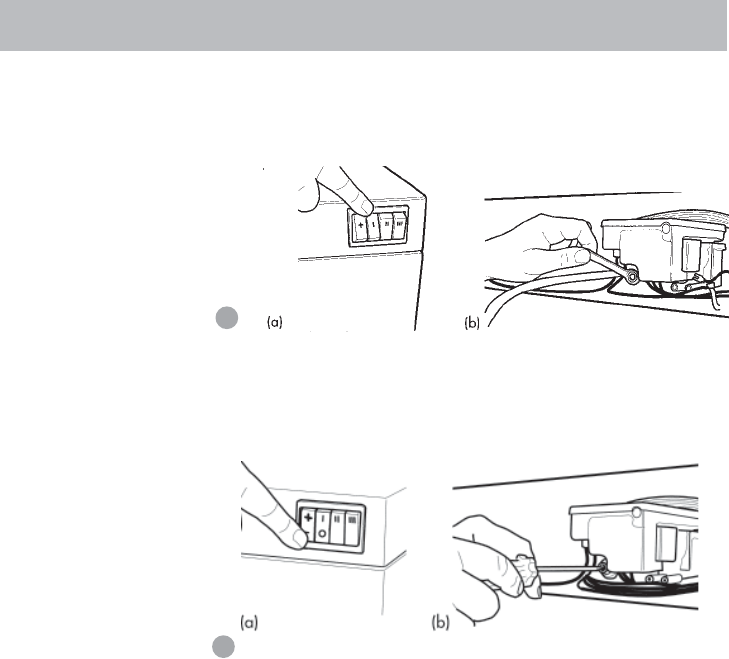

19. Switch the heat button back to “Low Flame’ position as indicated in

figure 24(a), retain spanner in position and using a screwdriver as

per figure 24(b) adjust the central screw control to give a pressure

reading of 0.3 kPa for Natural Gas and 1.1 kPa for LPG. (Turn clock-

wise to increase pressure and anticlockwise to decrease pressure).

20. Switch burners off and remove the manometer tube. Tighten pressure

test point by turning the captive screw fully clockwise.

Replace plastic cap. Ensure the little lug is positioned towards lower

right hand side to clear the control.

21. Refit the lower front cover, making sure not to damage the power cord.

22. Follow User Instructions to turn on heater and test for correct operation

before leaving.

23.The heater flames should be stable, not lifting from burner and the logs

should glow after approximately 15 minutes operation on HIGH set-

ting.

The heater has been designed to burn with luminous flames, which

mimic natural log combustion, and may exhibit slight carbon deposi-

tion. If heavy carbon deposits occurs or flames impinge on the roof of

the combustion chamber, turn the appliance off and contact the service

agent in your state.

24.If after following these installation instructions,and the trouble shooting

chart on page 22-23, the heater does not perform correctly contact the

our Technical Services Department. For contact details please refer page

21.

23

24

Important:

To achieve the correct

visual flame effect:

On Propane the gas

pressure must be set at

2.65 kPa with burner

operating on maximum

setting.

On Natural Gas the gas

pressure must be set at

0.75kPa.