10

2. Screw the water supply manifold into the

boiler outlet tapping “O.”

3. Orient the manifold with the relief valve on

top.

4. Screw the relief valve into manifold tapping

“RV”.

i

This installation is not complete until the

relief valve is installed.

PIPE THE RELIEF VALVE DISCHARGE

to a location where it will not harm

people or damage property. The relief valve may

discharge scalding hot water or steam.

BLOCKING THE RELIEF VALVE may

result in boiler explosion.

5. Screw the temperature-pressure gage into

manifold tapping “G”.

6. Connect the system supply to the open end

of the manifold "S" using a 1¼” male NPT

tting.

5. CONNECT GAS PIPING

Size gas piping according to Appendix C – Gas

Piping

SHUT OFF GAS SUPPLY before

servicing the boiler.

ALL GAS PIPING MUST BE GAS

TIGHT. Use gas rated thread compound

on all threaded joints to avoid leaks, which may

result in re or explosion.

SIZE GAS PIPING, regulators, valves,

and meters so as to provide an adequate

gas ow and pressure to the boiler during

operation. Failure to do so may cause poor

combustion, noise, injury, or death.

1. Remove boiler door, locate gas valve and

remove plastic shipping plug.

2. Thread a ¾" x 1½" nipple, a 90° street

elbow, or a Honeywell ange onto the gas

valve and pipe through the slot in the left

jacket panel (Figure 5-a). In Canada, close

nipples and street ells are not approved for

use as gas piping.

3. Pipe through the left jacket panel, and

complete drip leg as shown (Figure 5-a).

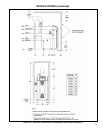

6. CONNECT BOILER WATER PIPING

General system piping guidelines are included in

Appendix D—System Piping.

Additionally, for this particular boiler install piping

shown below (Figure 6-a).

6-a

1. Apply sealant to all threads.

RV

S

R

O

G

D

5-a