12. Reconnect pressure tubes to pressure switches. See diagram

on main furnace door for proper location of tubes. Be sure

tubes are not kinked. (See Fig. 8.)

13. Turn on gas and electrical supplies to furnace.

14. Check furnace operation through 2 complete heat operating

cycles. Check area below inducer housing, vent pipe, and

condensate trap to ensure no condensate leaks occur. If

leaks are found, correct the problem.

15. Check for gas leaks.

WARNING: Never use matches, candles, flame, or

other sources of ignition to check for gas leakage. Use a

soap-and-water solution. Failure to follow this warning

could result in a fire, personal injury, or death.

16. Replace main furnace door.

VI. SERVICING HOT SURFACE IGNITOR

The ignitor does NOT require annual inspection. Check ignitor

resistance before removal.

1. Turn off gas and electrical supplies to furnace.

2. Remove main furnace door.

3. Disconnect ignitor wire connection.

4. Check ignitor resistance.

a. Using an ohm meter, check resistance across both ignitor

leads in connector.

b. Cold reading should be between 45 ohms and 90 ohms.

c. If ohm reading is higher than 110 ohms, ignitor is

cracked and must be replaced.

5. Remove ignitor assembly.

CAUTION: Allow ignitor to cool before removal. Nor-

mal operation temperatures exceed 2000°F.

a. Do not remove ignitor from bracket while assembly is in

furnace. Using a 1/4 in. nutdriver, remove screw secur-

ing bracket and ignitor assembly to bottom of burner

box. The screw in the bracket is always located toward

outside of burner box. The screw may be hidden by inlet

box or inlet pipe, but can be removed without removing

either. After removing screw, slide ignitor and bracket

toward outside of burner box and pull straight out.

CAUTION: The ignitor is fragile. DO NOT allow it to

hit the side of the burner box opening while removing or

replacing it.

b. Inspect ignitor for a white area indicating a crack may be

present. If found, replace ignitor.

NOTE: A small crack cannot be seen on a new ignitor. After a

period of operation, a white area will be visible around the crack.

c. If replacement is required, replace ignitor on ignitor

bracket external to furnace to avoid damage as the

silicon portion is very brittle and will easily crack or

shatter.

d. To remove ignitor from ignitor bracket, remove screw

holding ignitor ceramic block to bracket and pull ce-

ramic block out of bracket.

6. To replace ignitor/ignitor assembly, reverse items 5a

through 5d.

7. Reconnect ignitor wire connection.

8. Turn on gas and electrical supplies to furnace.

9. Verify ignitor operation by initiating control board self-test

feature or by cycling thermostat.

10. Replace main furnace door.

VII. ELECTRICAL CONTROLS AND WIRING

CAUTION: There may be more than 1 electrical supply

to the unit. Check accessories and cooling unit for

additional electrical supplies.

The electrical ground and polarity for 115-v wiring must be

maintained properly. Refer to Fig. 11 for field wiring information

and to Fig. 16 for unit wiring information.

NOTE: If the polarity is not correct, the STATUS LED on the

control center will flash rapidly and prevent the furnace from

operating. The control system also requires an earth ground for

proper operation of the control center and flame sensing.

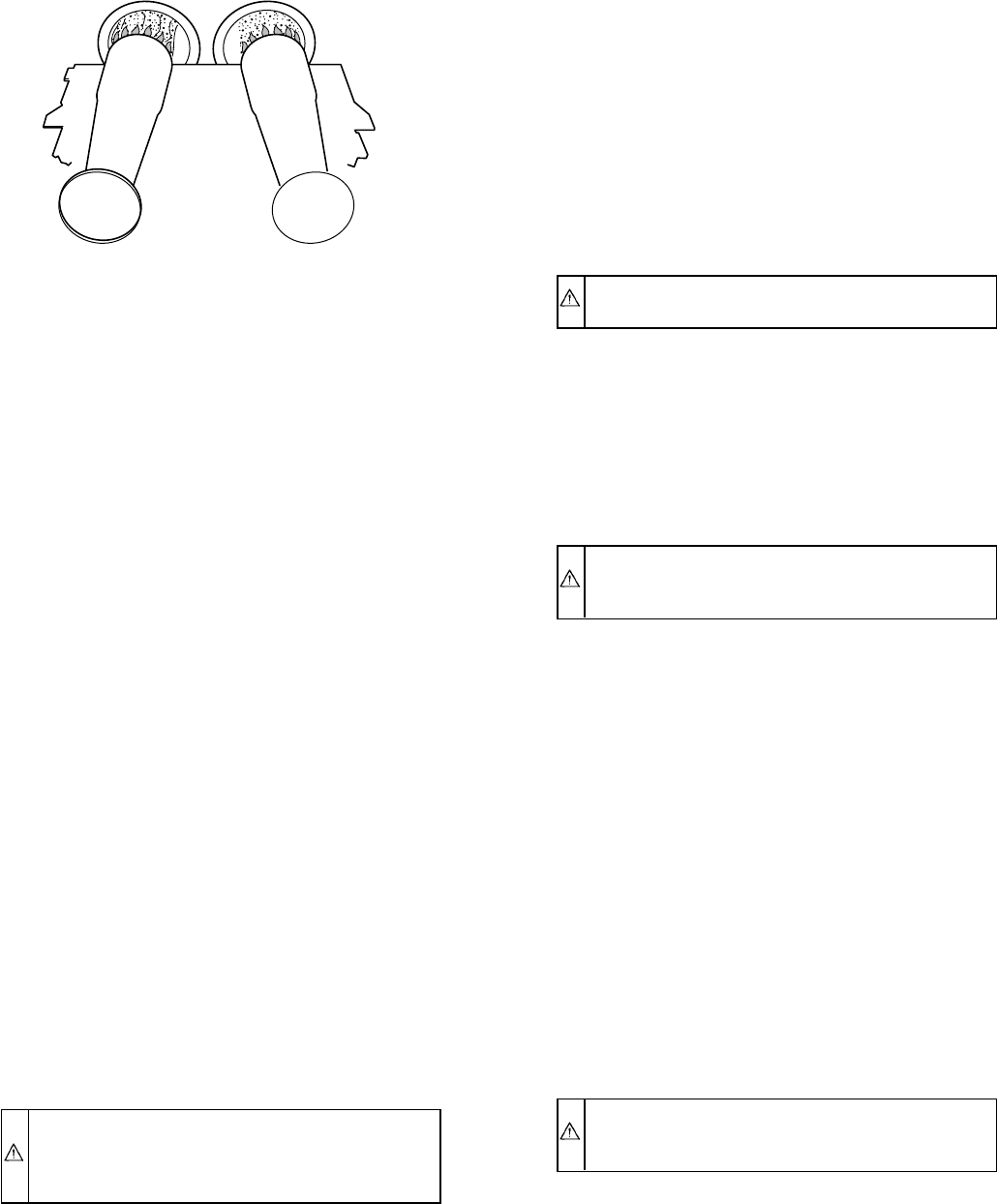

Fig. 9—Burner Flame

A89020