—8—

Table 4 — Refrigerant Specialties Part Numbers

*A filter drier is shipped loose with the 575B072 units.

†Bushings required.

**Factory Installed.

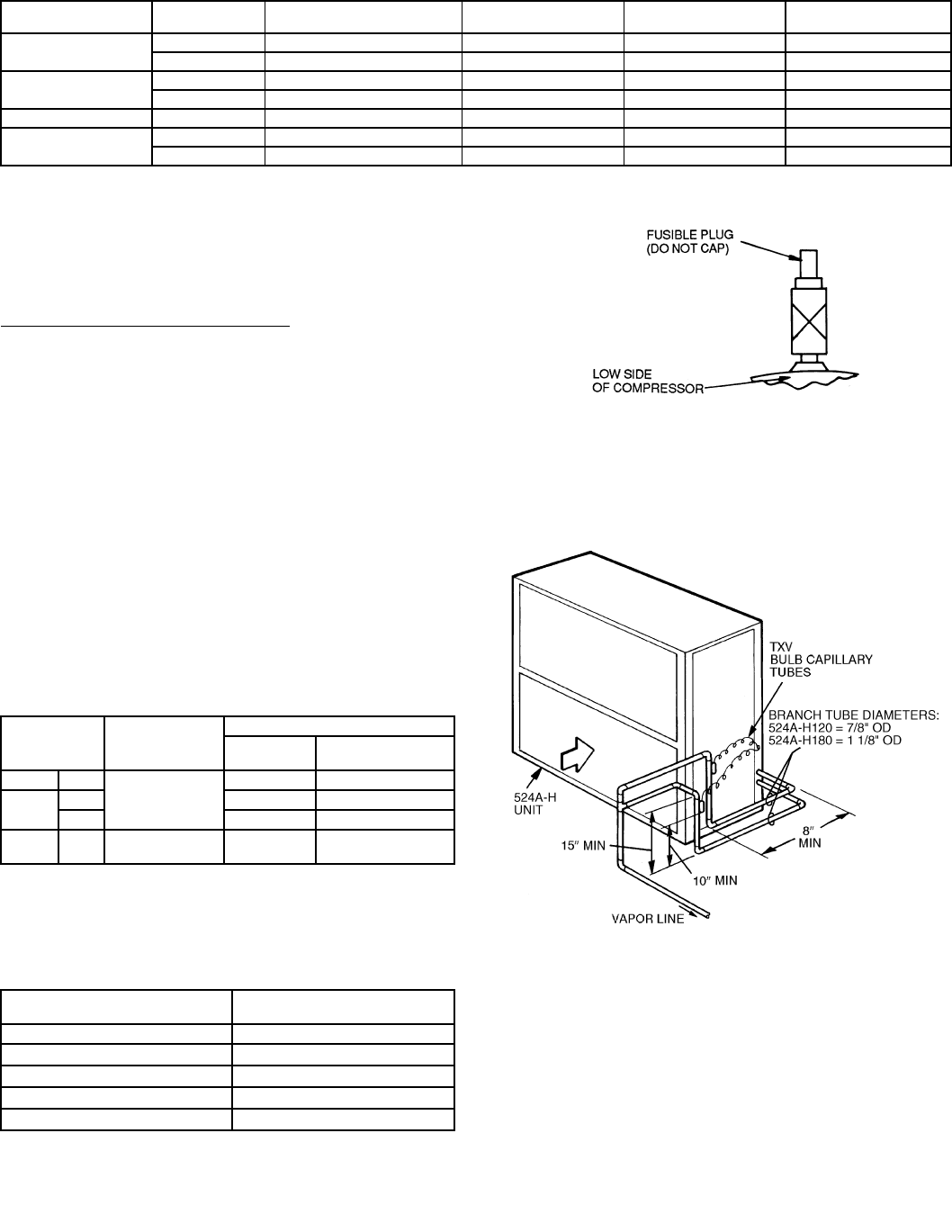

F. Provide Safety Relief

A fusible plug is located on the compressor crankcase or in

the liquid line. See Fig. 6. Do not cap this plug. If local code

requires additional safety devices, install them as directed.

Head Pressure Control (541A180 only)

Fan cycling for head pressure control is a standard offering

but is functional on the cooling cycle only. Number 2 fan

cycles as a function of liquid pressure. Fan cycling pressure

switch cycles the fan off at 160 ± 10 psig as pressure

decreases and cycles back on at 255 ± 10 psig. Switch is auto-

matically bypassed in heating cycle. Table 5 shows minimum

outdoor air temperature for full cooling capacity.

G. Vapor Line Piping Procedure

Connect system vapor line to the vapor line stub on the out-

door unit and the vapor stubs on the indoor unit. At the

indoor unit, construct vapor piping branches as shown in

Fig. 7 for good mixing of the refrigerant leaving the indoor

coil during cooling. This will ensure proper TXV (thermo-

static expansion valve) bulb sensing.

Where vapor line is exposed to outdoor air, line must be insu-

lated. See Table 6 for insulation requirements.

Table 5 — Minimum Outdoor Air

Operating Temperature

*Applies to Cooling mode of operation only.

†Wind baffles (field-supplied and field-installed) are recommended for

all units with low ambient head pressure control. Refer to Low Ambient

Control Installation Instructions (shipped with accessory) for details.

Table 6 — Insulation for Vapor Line Exposed

to Outdoor Conditions

*Recommended vapor line insulation for piping exposed to outdoor

conditions to prevent loss of heating during heating cycle. When vapor

line goes through interior spaces, insulation should be selected to pre-

vent condensation on cooling cycle. Heating capacity should be

reduced 1000 Btuh if over 35 ft of vapor line with

3

/

4

in. insulation is

exposed to outdoor conditions.

†Closed cell foam insulation with a thermal conductivity of: 0.28 Btu

• in./ft

2

• h • °F.

UNIT

LIQUID LINE

SIZE

LIQUID LINE

SOLENOID VALVE (LLSV)

LLSV COIL SIGHT GLASS FILTER DRIER

575B072

1

/

2

″ 200RB GS-1928 5T4 AMG-24/50-60 AMI1TT4 *

5

/

8

″ 200RB GS-1929 5T5 AMG-24/50-60 AMI1TT5 *

575C090

3

/

8

″ 200RB GS-1928 5T4† AMG-24/50-60 AMI1TT3 P504-8083S

1

/

2

″ 200RB GS-1928 5T4 AMG-24/50-60 AMI1TT4 P504-8084S

575C120

1

/

2

″ 200RB GS-1928 5T4 AMG-24/50-60 AMI1TT4 P504-8164S

541A180

5

/

8

″ ** ** AMI1TT5 P504-8085S Qty 2

3

/

4

″ ** ** AMI1TT5 P504-8085S Qty 2

UNIT

%

COMPRESSOR

CAPACITY

MINIMUM OUTDOOR TEMP — F*

Standard

Unit

Head Pressure

Control†

575B 072

100

00

575C

090 35 –20

120 35 –20

541A 180

100

67

23

36

–20

–20

LENGTH OF EXPOSED

VAPOR LINE*

INSULATION THICKNESS†

ft in.

10

3

/

8

25

1

/

2

35

3

/

4

50

3

/

4

Fig. 6 — Location of Fusible Plug —

541A180 Unit

LEGEND

Fig. 7 — Vapor Line Branch Piping Details

TXV — Thermostatic Expansion Valve