—18—

SEQUENCE OF OPERATION

I. 575B072 UNITS

When power is supplied to unit, the transformer (TRAN) and

crankcase heater (CCH) are energized.

A. Cooling

On a call for cooling, the thermostat completes the following

circuits: R-G, R-Y, and R-O. If the compressor recycle delay of

3 minutes is complete, the compressor and outdoor fan start.

The reversing valve is energized for cooling and the indoor-

fan motor starts.

When the thermostat is satisfied, the circuits are opened,

and the compressor, outdoor-fan motor, and indoor-fan motor

stop. The reversing valve is deenergized.

B. Heating

On a call for heating, the thermostat completes the following

circuits: R-G and R-Y. If the compressor recycle delay of

3 minutes is complete, the compressor and outdoor fan start.

The indoor-fan motor will also start.

If room temperature continues to fall, the thermostat

completes circuit R-W. If the optional electric heat package is

used, the heat relay is energized, and the electric heaters are

energized.

When the thermostat is satisfied, the circuits are opened,

and the compressor, outdoor-fan motor, heaters, and indoor-

fan motor stop.

C. Defrost

Defrost board (DB) is a time and temperature control, which

includes a field-selectable time period between checks for

frost (30, 50, and 90 minutes). Electronic timer and defrost

cycle start only when contactor is energized and defrost ther-

mostat (DFT) is closed (below 28 F).

Defrost mode is identical to Cooling mode, except outdoor-fan

motor (OFM) stops and a bank of supplemental electric heat

turns on to warm air supplying the conditioned space.

Defrost mode is terminated when the DFT reaches 65 F.

D. Air Circulation

When the fan switch is at FAN ON, the indoor-air fans oper-

ate continuously to provide ventilation. The thermostat

operates the other components as described above.

E. Emergency Heat Cycle

If the compressor is inoperative due to a tripped safety

device, the second stage of the thermostat automatically

energizes the indoor-air fan and the electric resistance heat-

ers (if equipped).

II. 575C090,120 UNITS

When power is supplied to unit, the transformer (TRAN) is

energized. The crankcase heater is also energized.

A. Cooling

With the thermostat subbase in the cooling position, and

when the space temperature comes within 2° F of the cooling

set point, the thermostat makes circuit R-O. This energizes

the reversing valve solenoid (RVS) and places the unit in

standby condition for cooling.

As the space temperature continues to rise, the second stage

of the thermostat makes, closing circuit R-Y. When compres-

sor time delay (5 ± 2 minutes) is completed, a circuit is made

to contactor (C), starting the compressor (COMP) and

outdoor-fan motor (OFM). Circuit R-G is made at the same

time, energizing the indoor-fan contactor (IFC) and starting

the indoor-fan motor (IFM) after one-second delay.

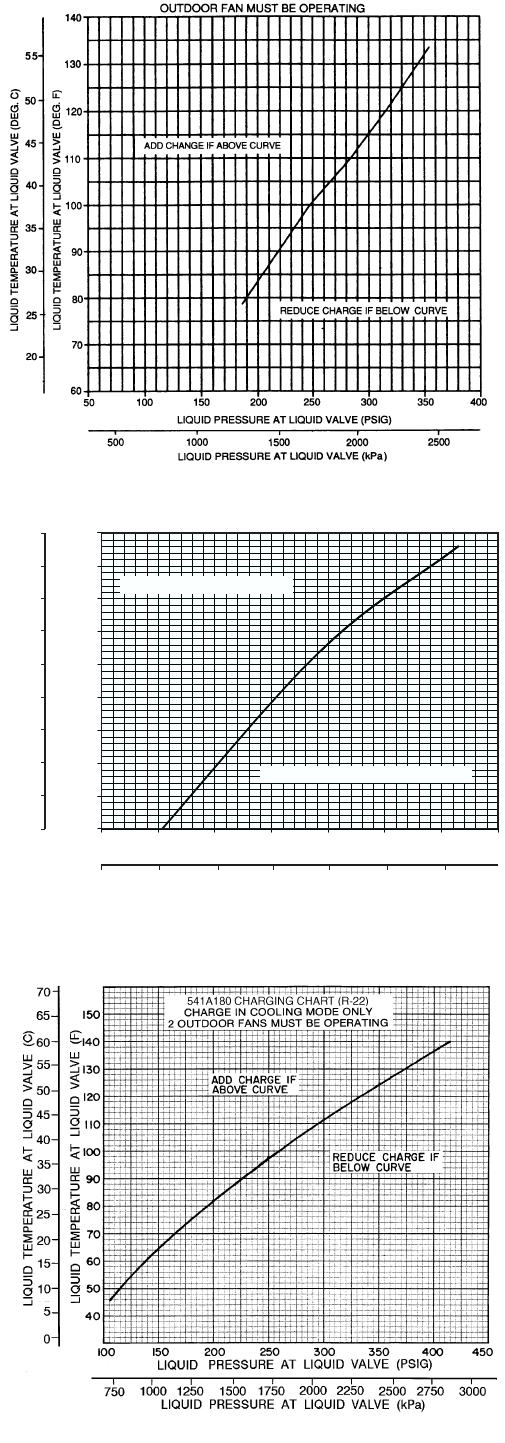

Fig. 19A — 575B072 Charging Chart

Fig. 19B — 575C090,120 Charging Chart

50

LIQUID PRESSURE AT LIQUID VALVE (PSIG)

LIQUID TEMPERATURE AT LIQUID VALVE (F)

344

LIQUID PRESSURE AT LIQUID VALVE (Kilopascals)

ADD CHARGE IF ABOVE CURVE

REDUCE CHARGE IF BELOW CURVE

50

60

70

80

90

100

110

120

130

140

100

150 200 250 300 350 40

0

689

1034

1379

1724

2069

2414

LIQUID TEMPERATURE AT LIQUID VALVE (C)

10

16

21

27

32

38

43

49

54

60

Fig. 19C — 541A180 Charging Chart