NOTE

THE LOW FIRE ADJUSTMENT SHOULD

RESULT IN A GAS PRESSURE ON THE

BURNER MANIFOLD EQUAL TO 1" WATER

COLUMN FOR NATURAL GAS AND 3" FOR

PROPANE GAS.

2.1.5 MINIMUM INPUT ADJUSTMENT -

COMBINATION GAS VALVES (VR850 OR

VR852)

The minimum input on these gas valves is NOT

adjustable. The maximum input must be properly

set as outlined in Lighting Instructions. See the

manufacturer's instructions on the VR850 or

VR852 included in the Boiler Manual for further

information.

2.1.6 MINIMUM INPUT ADJUSTMENT - DUAL

DIAPHRAGM GAS VALVE HIGH/LOW BY-PASS

SYSTEM

The minimum input on this control system is NOT

adjustable. The maximum input must be properly

set as outlined in Lighting Instructions. This

system consists of two V48A (120 volt coil) or two

V88A (24 volts coil) diaphragm gas valves which

are piped in parallel. The minimum input is

controlled by an orifice plug installed in a coupling

in the by-pass piping (low fire valve piping), sized

for approximately 1" w.c. manifold pressure at low

fire natural gas (2" w.c. if propane gas). When the

high fire gas valve is not activated, gas flows only

through the bypass piping. When the high fire gas

valve is activated, gas will flow though both

valves achieving full input.

2.2 FIRING RATE ADJUSTMENT - GAS METER READINGS

2.2.1 CHECKING BURNER INPUT

The burner input rate can be checked by taking

readings from the gas meter. Please note

checking the rate with a meter is the only way to

be sure of input. Manifold readings are only an

approximate value and may vary from unit to unit.

In order to obtain accurate data, there must be no

other appliances using gas from the same meter

while the burner input rate is being checked. The

test hand on the meter should be timed for

several revolutions. The input rate in cubic feet

per hour is

calculated from this timing. The method is

described in Lighting Instructions. If the meter is

not calibrated for gas temperature and pressure,

correction factors must be applied to determine

correct rate in SCFH (standard cubic feet per

hour). Consult the National Fuel Gas Code (ANSI

Z223.1, NFPA 54) or the local gas utility for

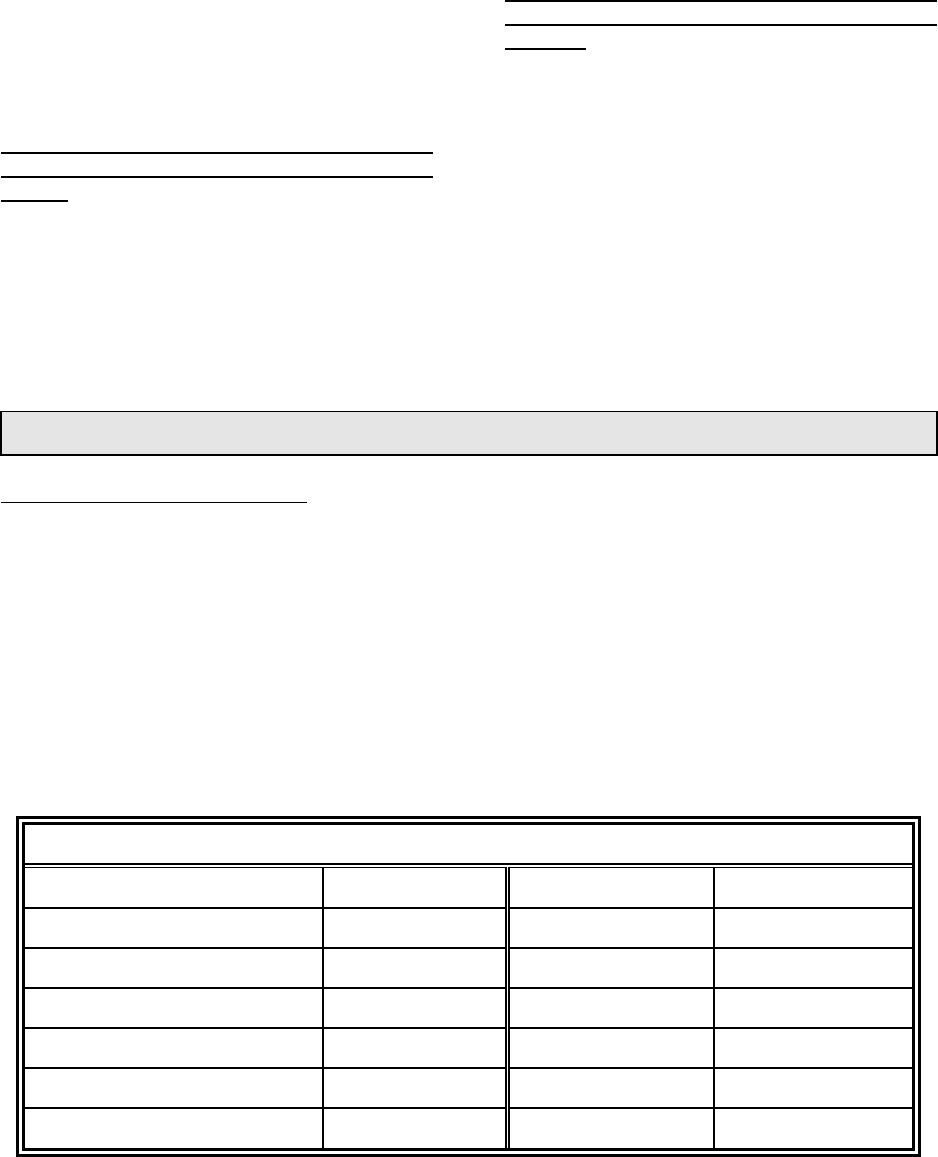

further information. Refer to Table 2.2A for

correction factors for the gas pressure at the

meter. Refer to Table 2.2B for the gas

temperature correction factors.

Table 2.2A - Pressure Correction Table 2.2B - Temperature Correction

Gas Pressure at Meter Correction Factor Gas Temp. at Meter Correction Factor

7" w.c. 1.017 40 F 0.920

14" w.c. 1.034 50 F 0.902

21" w.c. 1.051 60 F 0.885

1 psig 1.061 70 F 0.868

2 psig 1.136 80 F 0.852

5 psig 1.340 90 F 0.836