2

Useful Sewing Tips 69

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

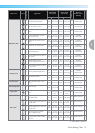

■ If thick seams are being sewn and the fabric does

not feed at the beginning of stitching

The fabric may not feed when thick seams are

being sewn and the presser foot is not level, as

shown below. In this case, use the presser foot

locking pin (black button on the left side of zigzag

foot “J”) so that the presser foot remains level

while sewing, allowing the fabric to be fed

smoothly.

a Sewing direction

a

Raise the presser foot lever.

b

Align the beginning of stitching, and then

position the fabric.

c

While holding zigzag foot “J” level, hold the

presser foot locking pin (black button on the

left side) pressed in, and lower the presser foot

lever.

a Presser foot locking pin (black button)

d

Release the presser foot locking pin (black

button).

X The presser foot remains level, allowing the

fabric to be fed.

• After the seam is sewn, the presser foot will

return to its original angle.

CAUTION

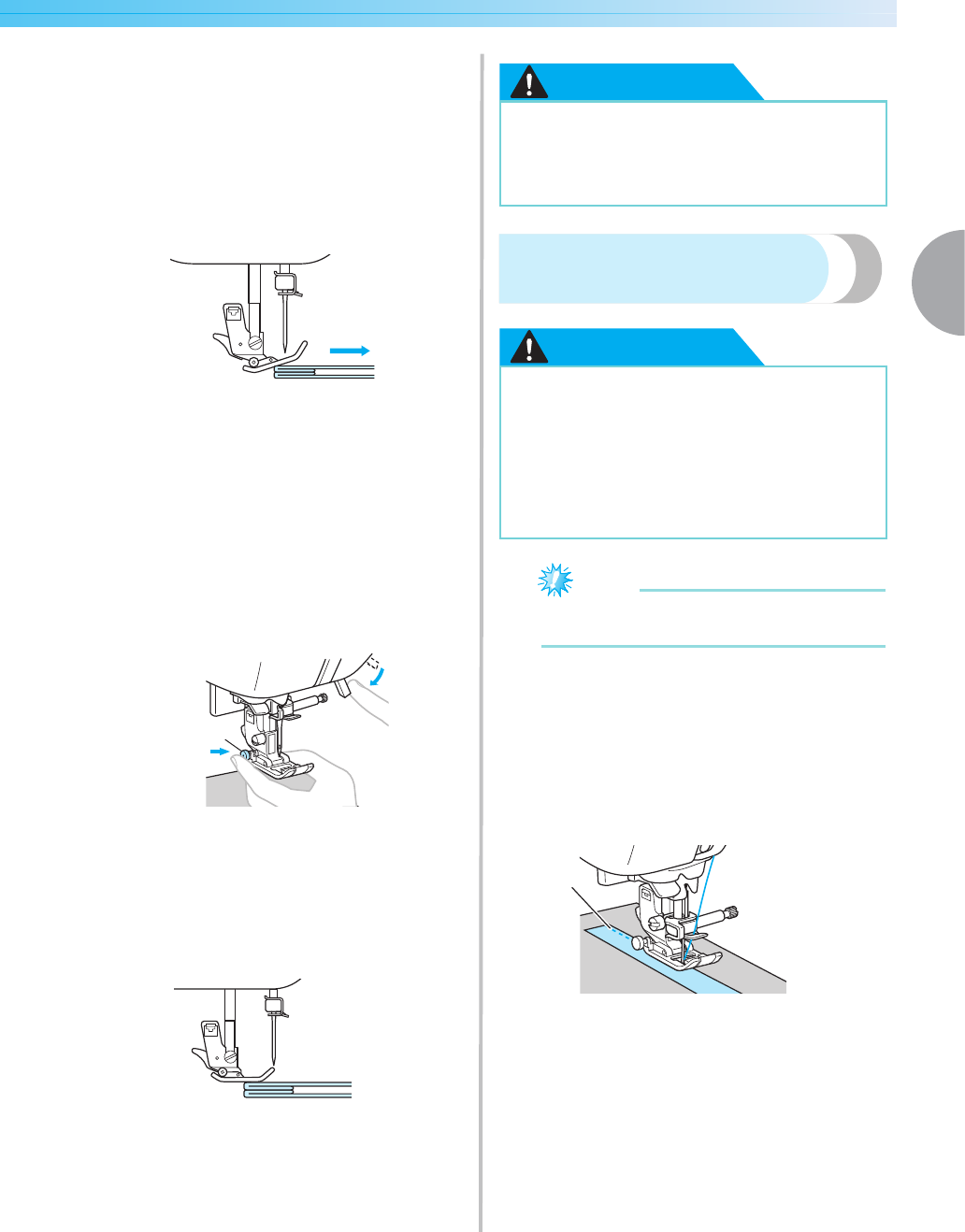

Sewing hook-and-loop

fastener

CAUTION

Note

z Before starting to sew, baste the fabric and

hook-and-loop together.

Make sure that the needle passes through the hook-

and-loop fastener by turning the handwheel and

lower the needle into the hook-and-loop fastener

before sewing. And then, sew the edge of the hook-

and-loop fastener at a slow speed.

If the needle does not pass through the hook-and-

loop fastener, replace the needle with the needle for

thick fabrics (page 39).

a Edge of the hook-and-loop fastener

a

a

z If fabric more than 6 mm (15/64 inch)

thick is sewn or if the fabric is pushed

with too much force, the needle may

bend or break.

z Use only the ungummed hook-and-loop

fastener designed for sewing. If the glue

adheres to the needle or the bobbin hook

race, it may cause malfunction.

z If the hook-and-loop fastener is sewn with

a fine needle (65/9-75/11), the needle

may bend or break.

a