26

—————

———————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————————

2

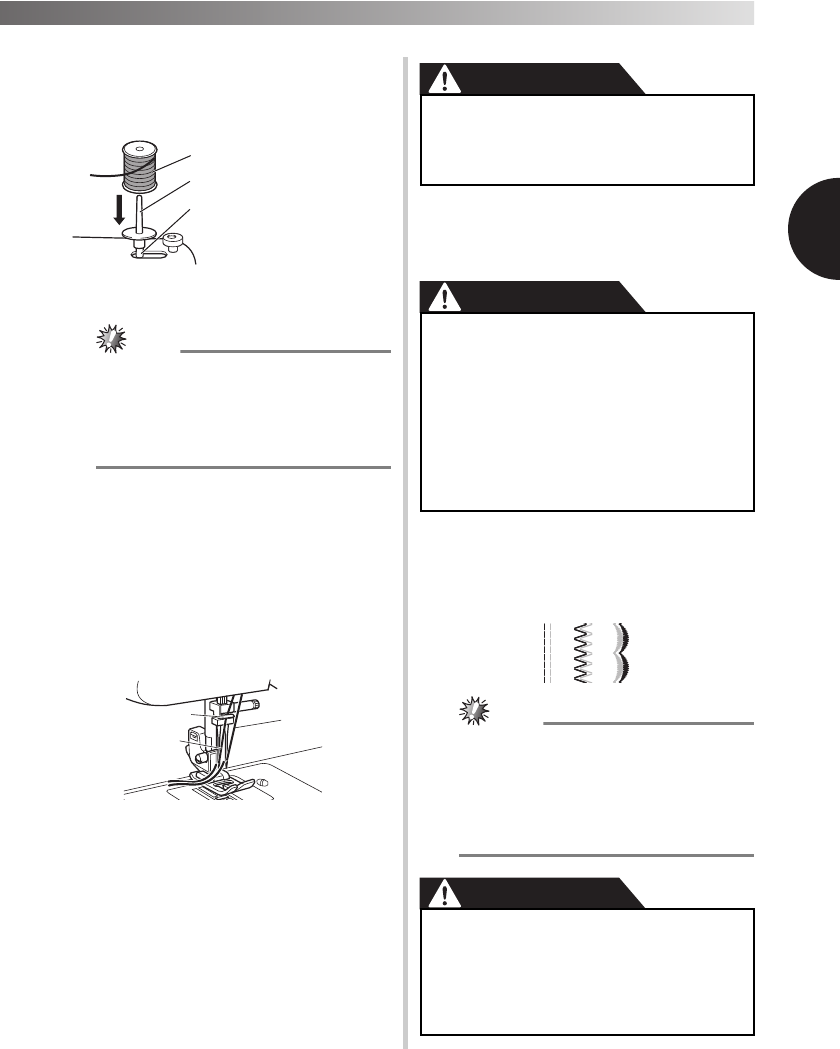

■ Attaching the extra spool pin

Insert the extra spool pin onto the end of the bobbin

winder shaft. Install the second thread spool onto

the extra spool pin.

■ Twin needle threading

You should thread each needle separately.

Note

Models equipped with a needle threader

● You cannot use the needle threader to

thread the twin needle. Instead, thread the

twin needle by hand, from front to back.

Using the needle threader may damage the

machine.

1

Thread the left needle.

Follow the same instructions for threading a

single needle (see page 17).

2

Thread the right needle.

Thread the right needle in the same way that

you threaded the left needle using the thread

from the spool on the extra spool pin, but do not

pass the thread through the guide above the

needle before you pass it through the eye of the

right needle.

1 Left needle thread passes through the needle

bar thread guide

2 Right needle thread passes in front of the needle

bar thread guide

3 Needle bar thread guide

3

Attach zigzag foot “J”.

For details on changing the presser foot, refer

to “Changing the presser foot” on page 8.

CAUTION

4

Turn on the machine.

5

Select a stitch.

CAUTION

6

Start sewing.

For details on starting to sew, refer to “Starting

sewing” on page 23.

X Two lines of stitching are sewn parallel to

each other.

Note

● When using the twin needle, the stitches

may become bunched together, depending

on the types of thread and fabric that are

used. If this occurs, increase the stitch

length. For details on adjusting the stitch

length, refer to “Stitch length dial” on

page 12.

CAUTION

1 Bobbin winder shaft

2 Extra spool pin

3 Thread spool

1

2

3

1

3

2

● When using the twin needle, be sure to

attach zigzag foot “J”, otherwise the

needle may break or the machine may be

damaged.

● After adjusting the stitch width, slowly

turn the handwheel toward you

(counterclockwise) and check that the

needle does not touch the presser foot. If

the needle hits the presser foot, the

needle may bend or break.

● When using the twin needle, make sure

the stitch width is not set above “2.5”

since this may cause the needle to hit the

needle plate and break.

● When changing the sewing direction, be

sure to raise the needle from the fabric,

and then raise the presser foot lever and

turn the fabric. Otherwise the needle

may break or the machine may be

damaged.