Internet Version for Reference Only

BRADFORD WHITE

Page 28

Copper Brute B4 Volume Water Heaters

Page 29

2. If the voltmeter reads voltage, the safety fuse and

the fusible link are good.

3. Replace the fusible link when an open circuit is

detected. An open fuse line indicates overheating

in the ue collector or compartment.

4. Check for leaks of the ue collector, vent pipe,

gaskets, and all connections.

5. Check the ue pipe for blockage.

6. Check heat exchanger ns for partial sooting.

5.2.7 Testing the Fuse

To test the fuse:

1. Clip a lead of the voltmeter to the grounding

terminal.

2. Touch the other voltmeter lead to the 24VAC

terminal on the ignition control.

3. If there is no voltage, replace the fuse. A blown

fuse is usually an indication of a short in the

24VAC circuit. It is important that the cause of

the short be found and repaired. Do not jumper or

bypass the fuse.

5.2.8 Testing the Ignition Control

(for spark ignition)

Caution

The ignition control and igniter operate on 120V

power. Keep this in mind while servicing the heater,

and take care to avoid electrical shock.

The ignition control provides power to the pilot,

opens the gas valve when there is a call for heat, and

senses when a ame is established. To test the ignition

control for spark ignition:

1. Clip one lead from the voltmeter to the yellow

wire terminal on the transformer.

2. Touch the other voltmeter lead to the red 24V

terminal on the ignition control.

3. If the voltmeter reads voltage, the temperature

control and the manual reset hi-limit switch are

not keeping the heater from ring.

4. Make sure the pilot burner is positioned next to

the main burner (see Figure 40) and there is no

soot or dirt on it.

5. Make sure the electrode (part of pilot assembly)

is clean, the terminal connection is tight, and the

ceramic insulator lead is at least 3/8 inch (9.5

mm) from the heater chassis and other metal

parts.

6. Check for proper spark gap.

Figure 40. Pilot location (spark ignition).

5.2.9 Testing the High Voltage

Ignition Lead

Connections must be tight, and silicone rubber

boots in place. Bare metal parts at the base of the

manifold bracket must be at least 3/8 inch (9.5 mm)

from other metal objects. To test the ignition lead:

1. Turn the control panel switch to on.

2. Make sure the temperature control is turned far

enough to call for heat. There will be a loud

clicking noise indicating the pilot electrode is

sparking.

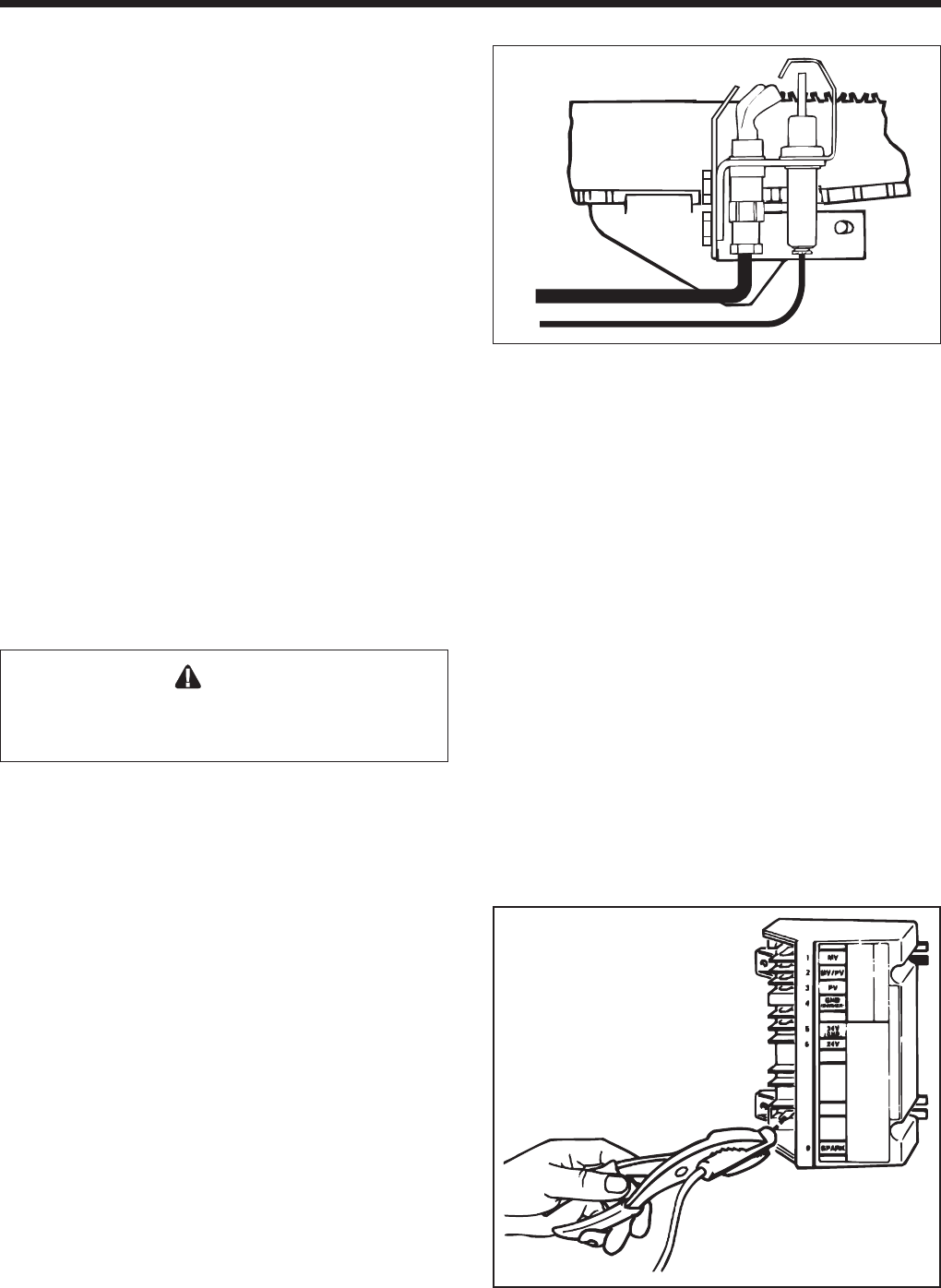

3. If no sparking is heard, pull the ignition lead

from the ignition control and hold the bare

terminal 1/8 to 3/16 inch (3.2 to 4.8 mm) from

the ignition stud with a pair of insulated pliers

(see Figure 41).

4. If a spark does not jump the gap, replace the

ignition control.

NOTE: The ignition control cannot be repaired

in the eld. If it does not operate properly, replace it.

Figure 41. High voltage ignition test.