2.5 ELECTRICAL SUPPLY

Mains supply: 230V ~, 50 Hz, 180 watts.

External fuse: 3A., Internal fuses: 2AT HRC(F1), and 1 AF (F2).

2.6 GAS SUPPLY

The boiler requires 2.76 m

3

/h (97.5 ft

3

/hr) of natural gas with a

calorific value of 37.78 MJ/m

3

(1014 Btu/ft

3

) or 1.07 m

3

/h (37.8

ft

3

/hr) of propane with a calorific value of 95.65 MJ/m

3

(2568

Btu/ft

3

). The meter governor should deliver a dynamic pressure

of 20 mbar (8in w.g.) at the appliance, equivalent to a pressure of

about 19-19.5 mbar at the gas valve on natural gas or 37.0 mbar

(14.8in w.g.) at the appliance for propane.

The gas meter and supply pipes must be capable of supplying

this quantity of gas in addition to the demand from any other

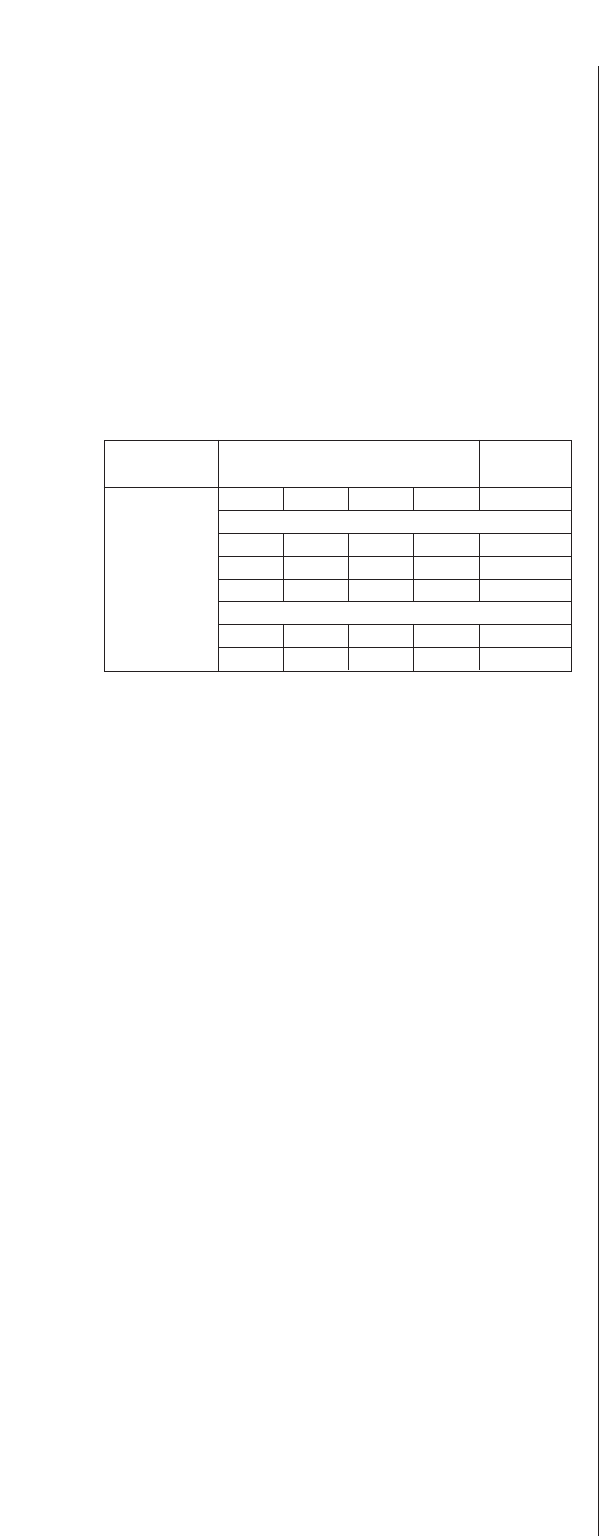

appliances being served. The table below gives an indication of

limiting gas pipe lengths and the allowance to be made for

fittings. Refer to BS6891 for further information.

The complete installation, including the gas meter, must be

tested for soundness and purged. Refer to BS 6891.

Note: Each fitting used in the gas line from the meter is

equivalent to a length of straight pipe which must be added to

the straight pipe length to give the total length.

i.e.: Bend = 0.5 metres, Tee = 0.5 metres, 90° Bend = 0.3

metres.

2.7 PACKING

The appliance and flue components are packaged separately.

2.8 GENERAL INSTALLATION

The appliance is for connection to a sealed system only.

The specified ventilation openings made into a wall or

compartment door must not be obstructed.

If the appliance is to be fitted into a compartment then the

compartment must conform to the requirements of BS 6798:

1987: Section 7.

Do not place anything on top of the appliance.

The clearances specified for servicing must be maintained.

2.9 FLUE

The appliance has a multi-directional fanned flue system.

The standard telescopic flue assembly length is from 127mm to

350mm.

Extension flue lengths available are from 350mm to 2500mm.

An optional vertical flue kit to provide for flue lengths up to

3000mm including vertical flue terminal.

A terminal guard, Type K2, GC 393 553, is available from Tower

Flue Components, Vale Rise, Tonbridge, TN9 1TB.

Do not allow the flue terminal fitted to the outside wall to

become obstructed or damaged.

A kit for internal fixing of the flue is available separately.

2.10 CONTROLS

The electronic control system and gas valve modulate the heat

input in response to the domestic hot water temperature and

central heating setting between minimum and maximum.

The Central Heating Temperature control knob provides for the

selection of domestic hot water only (Turned fully anti-clockwise)

or central heating and domestic hot water (Turned clockwise).

A facia mounted programmer is available as an optional extra. A

remote mounted programmer may be connected to the

appliance.

There is provision for the connection of a mains voltage room

thermostat and/or a frost thermostat.

The electronic controls prevent rapid cycling of the appliance in

the central heating mode.

2.11 SYSTEM NOTES

IMPORTANT

Check that no dirt is left in either the gas or water pipework as

this could cause damage to the appliance. The heating system

should be flushed and treated in accordance with the

recommendations of BS 7593:1992. Thoroughly flush cold water

mains supply and purge the gas supply before finally connecting

the appliance.

The water pipe connections throughout a sealed system must be

capable of sustaining a pressure of up to 3 bar.

Radiator valves must conform to the requirements of BS

2767:1991.

The relief valve discharge must be directed away from any

electrical components or where it would cause a hazard to the

user.

A drain cock to BS 2879 must be fitted to the lowest point of the

system.

For circuit design purposes it is important that due note is taken

of the information given in Table 3, section 3 relating to the

available pump head.

2.12 SHOWERS, BIDETS, TAPS AND MIXING VALVES

Hot and cold taps and mixing valves used in the system must be

suitable for operating at mains pressure.

Thermostatically controlled shower valves will guard against the

flow of water at too high a temperature.

Hot and cold mains fed water can be supplied direct to an over-

rim flushing bidet subject to local Water Company requirements.

With all mains fed systems the flow of water from the individual

taps will vary with the number of outlets operated

simultaneously and the cold water mains supply pressure to the

property. Flow balancing using “Ball-o-Fix” type valves is

recommended to avoid an excessive reduction in flow to

individual outlets.

2.13 SAFETY CONSIDERATIONS

The appliance must not be operated in a waterless condition.

The appliance must not be operated with the boiler inner casing

cover removed.

Work must not be carried out on the appliance without the gas

and electricity supplies being switched off.

Checks must be made to ensure that the ventilation openings

made into walls and partitions are unobstructed and the correct

size.

2.14 OPERATION

Domestic Hot Water:

With a demand for hot water the burner

will light at its maximum setting and then automatically adjust

its output to maintain the temperature of the delivered water.

When hot water is no longer required, the burner will extinguish.

The fan and pump may continue to run for a short period to

dissipate the residual heat from the appliance.

Central Heating: With a demand for heating the burner will light

at its minimum setting and gradually increase to give a

controlled temperature rise. When the required heating

temperature is achieved the output of the appliance is then

automatically adjusted to maintain the temperature of the

system. The output can reduce down to a minimum of 7.5 kW. If

the system no longer requires even the minimum output to

maintain the desired room temperature the burner will

extinguish. The fan and pump may continue to run to dissipate

the residual heat from the appliance. The appliance will remain

off for a fixed period before re-lighting to automatically meet the

system requirements.

Domestic Hot Water and Central Heating: The appliance will

supply heat to the central heating system as required. A demand

for domestic hot water at a tap or shower will override the

central heating requirement for the period of the domestic hot

water demand. When hot water is no longer required the

appliance will return to the central heating state and its normal

mode of operation. The fan may continue to run to dissipate the

residual heat from the appliance as necessary.

2.15 DOMESTIC SUPPLY

Devices capable of preventing the flow of expansion water must

not be fitted unless separate arrangements have been made.

3

Total length of gas supply pipe Pipe size

(metres) (Ømm)

36912

Propane

Gas Discharge

1.5 – – – 15

Rate

8.0 5.2 4.2 3.6 22

(m

3

/hr)

15.9 8.8 8.5 7.2 28

Natural Gas

8.7 5.8 4.6 – 22

18.0 12.0 9.4 – 28

Gas

Discharge

Rate

(m

3

/hr)