Manual 2100-324

Page 14

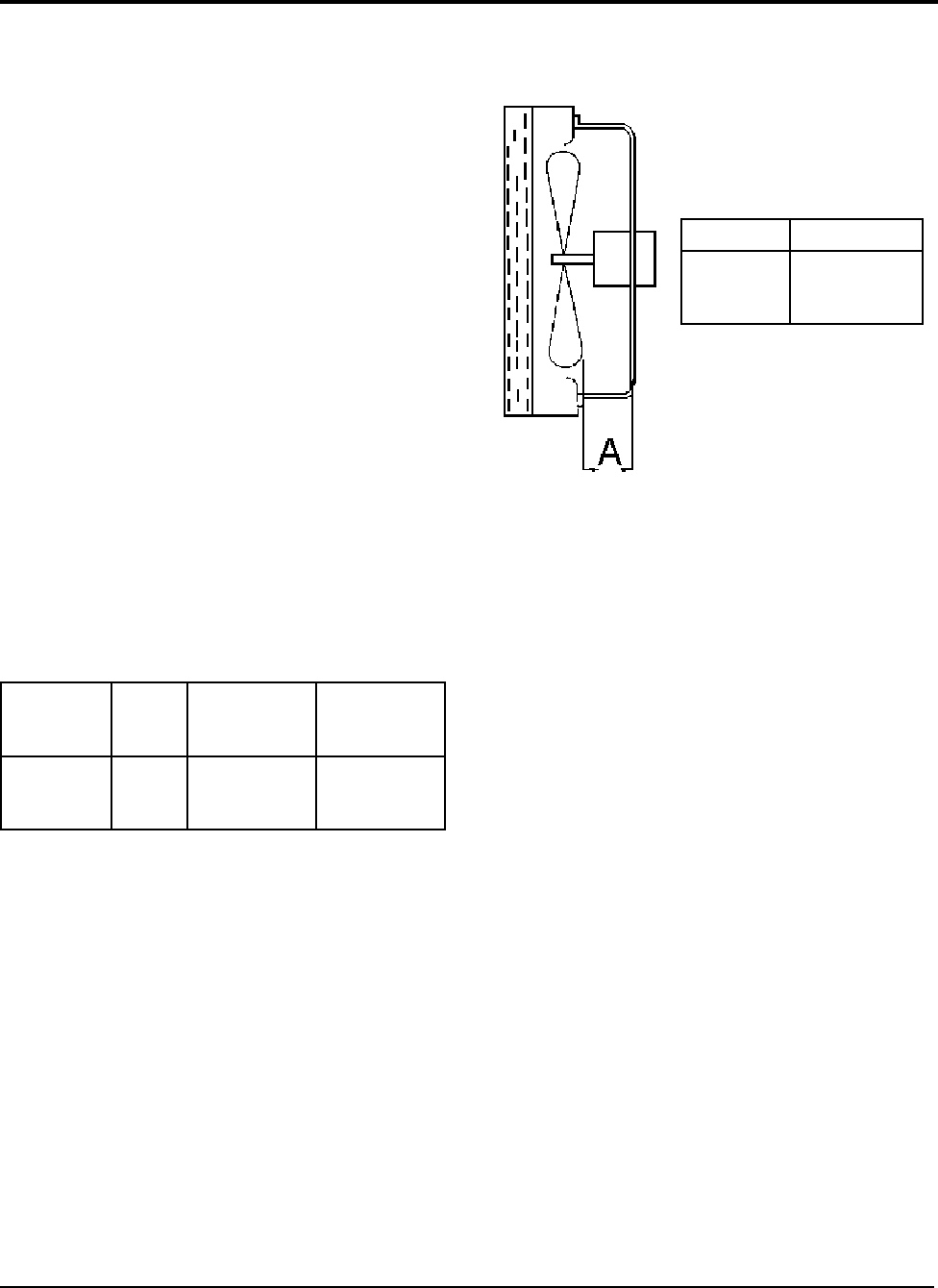

FAN BLADE SETTINGS

Shown in Figure 9 are the correct fan blade setting

dimensions for proper air delivery across the outdoor coil.

Any service work requiring removal or adjustment in the

fan and/or motor area will require that the dimensions

below be checked and blade adjusted in or out on the

motor shaft accordingly.

FIGURE 9

FAN BLADE SETTING DIMENSIONS

SUCTION AND DISCHARGE TUBE

BRAZING

Compliant Scroll compressors have copper plated steel

suction and discharge tubes. These tubes are far more

rugged and less prone to leaks than copper tubes used on

other compressors. Due to different thermal properties of

steel and copper, brazing procedures may have to be

changed from those commonly used.

•

To disconnect: heat joint Areas 2 and 3 slowly and

uniformly until braze material softens and the tube can

be pulled out of suction fitting. (See Figure 10.)

•

To connect:

– Recommended brazing materials: silfos with

minimum 5% silver or silver braze material with

flux.

– Reinsert tube into fitting.

– Heat tube uniformly in Area 1 moving slowly to

Area 2. When joint reaches brazing temperature,

apply brazing material. (See Figure 10.)

– Heat joint uniformly around the circumference to

flow braze material completely around the joint.

– Slowly move torch into Area 3 to draw braze

material into joint. (See Figure 10.)

– Do not overheat joint.

ledoMAnoisnemiD

3A2411P

1A8411P

1A0601P

"57.1

"57.1

"57.1

TABLE 9

The above suction line temperatures are based upon

80°F dry bulb/67°F wet bulb (50% RH) temperature and

rated airflow across the evaporator during cooling cycle.

ledoM

detaR

wolfriA

FeergeD59

DO

erutarepmeT

FeergeD28

DO

erutarepmeT

3A2411P

1A8411P

1A0610P

0041

0551

0071

95-75

75-55

94-74

06-85

16-95

65-45

SERVICE AND TROUBLESHOOTING

SERVICE HINTS

1. Caution homeowner to maintain clean air filters at all

times. Also, not to needlessly close off supply and

return air registers. This reduces air flow through the

system which shortens equipment service life as well

as increasing operating costs.

2. Check all power fuses or circuit breakers to be sure

that they are the correct rating.

3. Periodic cleaning of the outdoor coil to permit full and

unrestricted airflow circulation is essential.

PRESSURE SERVICE PORTS

High and low pressure service ports are installed on all

units so that the system operating pressures can be

observed. Pressure tables can be found in Table 10 in this

manual covering all models on cooling cycle. It is

imperative to match the correct pressure table to the unit

by model number.

REFRIGERANT CHARGE

The correct system R-22 charge is shown on the unit rating

plate. Optimum unit performance will occur with a

refrigerant charge resulting in a suction line temperature

(6” from compressor) as shown in Table 9.