5

CAUTION

In cold climates provide protection against freeze-up.

THE HEATER SHOULD BE LOCATED IN AN AREA WHERE

LEAKAGE OF THE TANK OR CONNECTIONS WILL NOT RESULT

IN DAMAGE TO THE AREA ADJACENT TO THE HEATER OR TO

LOWER FLOORS OF THE STRUCTURE.

When such locations

cannot be avoided, a suitable drain pan should be installed

under the heater, see fig. 1. The pan should have a minimum

length and width of at least 2 inches greater than the diameter of

the heater and should be piped to an adequate drain. Drain

pans suitable for these heaters are available from your dealer.

Water heater life depends upon water quality, water pressure

and the environment in which the water heater is installed.

Water heaters are sometimes installed in locations where

leakage may result in property damage, even with the use of a

drain pan piped to a drain. However, unanticipated damage

can be reduced or prevented by a leak detector or water shut-off

device used in conjunction with a piped drain pan. These

devices are available from some plumbing supply wholesalers

and retailers, and detect and react to leakage in various ways:

• Sensors mounted in the drain pan that trigger an alarm or turn

off the incoming water to the water heater when leakage is

detected.

• Sensors mounted in the drain pan that turn off the water supply

to the entire home when water is detected in the drain pan.

• Water supply shut-off devices that activate based on the water

pressure differential between the cold water and hot water

pipes connected to the water heater.

• Devices that will turn off the gas supply to a gas water heater

while at the same time shutting off its water supply.

WARNING

DO NOT INSTALL THIS WATER HEATER DIRECTLY ON A

CARPETED FLOOR. A FIRE HAZARD MAY RESULT. Instead

the water heater must be placed on a metal or wood panel

extending beyond the full width and depth by at least 3 inches

(76.2mm) in any direction. If the heater is installed in a carpeted

alcove or closet, the entire floor shall be covered by the panel.

Also, see DRAINING.

WARNING

For California installation this water heater must be braced,

anchored, or strapped to avoid falling or moving during

an earthquake. See instructions for correct installation

procedures. Instructions may be obtained from your local dealer,

wholesaler, public utilities or California’s Office of the State

Architect, 400 P Street, Sacramento, CA 95814.

WATER CONNECTIONS

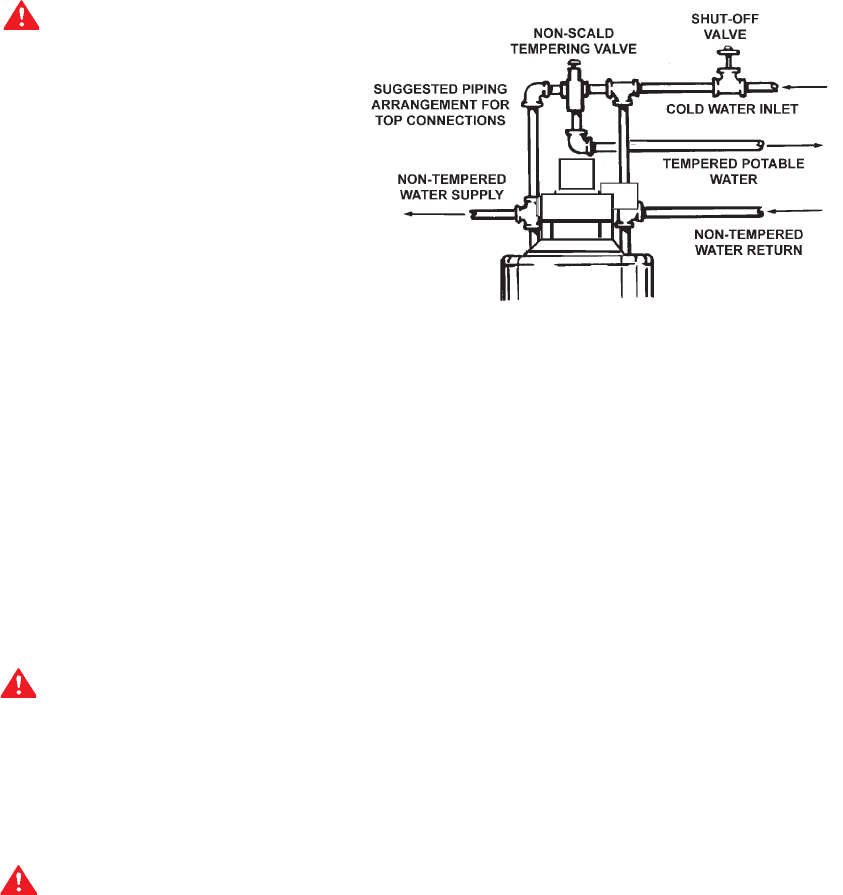

Refer to figure 1 for typical installation. A suitable pipe thread

sealant must be used to prevent leakage.

WATER (POTABLE) HEATING AND SPACE

HEATING

1. All piping components connected to this unit for space heating

applications shall be suitable for use with potable water.

2. Toxic chemicals, such as those used for boiler treatment,

shall NEVER be introduced into this system.

3. This unit may NEVER be connected to any existing heating

system or component(s) previously used with a non-potable

water heating appliance.

4. When the system requires water for space heating at

temperatures higher than required for domestic water

purposes, a tempering valve must be installed. Please refer

to Figure 2 for suggested piping arrangement.

FIGURE 2

CLOSED WATER SYSTEM

A closed system will exist if a back-flow preventer (check valve),

or similar device is installed in the cold water line between the

water heater and the street main (or well). Excessive pressure

may develop due to the thermal expansion of heated water

causing premature tank failure or intermittent relief valve

operation. This type of failure is not covered by the limited

warranty. An expansion tank may be necessary in the cold water

supply to alleviate this situation, see fig. 1. Contact the local

plumbing authority.

If the temperature and pressure relief valve on the appliance

discharges periodically, this may be due to thermal expansion

in a closed water supply system. Contact the water supplier or

local plumbing inspector on how to correct the situation.

Do not

plug the temperature and pressure relief valve.

GAS CONNECTIONS

The minimum gas supply pressure is 5.0" W.C for natural gas

(11.0" W.C. for propane).

THE HEATER IS NOT INTENDED FOR OPERATION AT HIGHER

THAN 14.0'' WATER COLUMN SUPPLY PRESSURE. EXPOSURE

TO HIGHER GAS SUPPLY PRESSURE MAY CAUSE DAMAGE

TO THE CONTROL WHICH COULD RESULT IN FIRE OR

EXPLOSION.

If overpressure has occurred such as through

improper testing of gas lines or emergency malfunction of the

supply system, the control must be checked for safe operation.

Make sure that the outside vents on the supply regulators and

the safety vent valves are protected against blockage. These

are parts of the gas supply system not the heater. Vent blockage

may occur during ice storms.

IT IS IMPORTANT TO GUARD AGAINST CONTROL FOULING

FROM CONTAMINANTS IN THE GAS WAYS. SUCH FOULING

MAY CAUSE IMPROPER OPERATION, FIRE OR EXPLOSION.

All piping must comply with local codes and ordinances or with

the National Fuel Gas Code (ANSI Z223.1/ NFPA-54) whichever

applies. Copper and brass tubing and fittings (except tin lined

copper tubing) shall not be used.

REFER TO FIG. 1 FOR CONNECTION DETAILS. BEFORE

ATTACHING THE GAS LINE BE SURE THAT ALL GAS PIPE IS

CLEAN ON THE INSIDE.

TO TRAP ANY DIRT OR FOREIGN MATERIAL IN THE GAS

SUPPLY LINE, A DIRT LEG (SOMETIMES CALLED DRIP LEG)

MUST BE INCORPORATED IN THE PIPING, FIG. 1.

The dirt leg

must be readily accessible. Install in accordance with

recommendations of serving gas supplier. Refer to the current

edition of National Fuel Gas Code, ANSI Z223.1/NFPA.