8

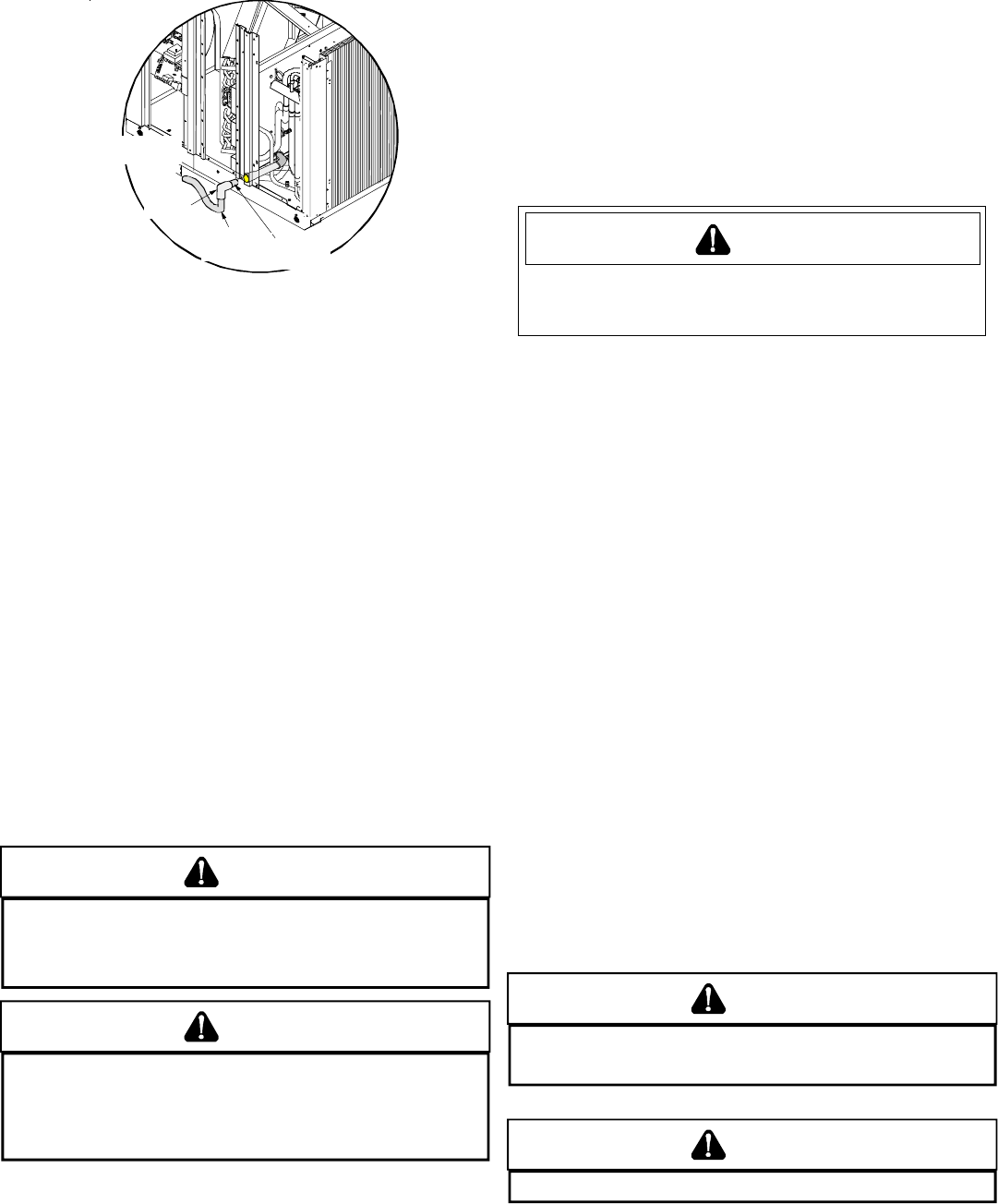

2-1/2" of

3/4" PVC

Condensate

Drain Trap

90° ELL

1-1/2" Minimum

drop at outlet

Figure 13 - Condensate Drain Connection

NORMAL SEQUENCE OF OPERATION

NOTE: There is a fan delay on initial power to unit before the low

voltage board resets and is operational.

1. Thermostat calls for heating or cooling. The compressor and

outdoor fan are energized.

2. Approximately 10 seconds later, the indoor fan starts.

3. The unit will deliver heating or cooling to the conditioned

space until the thermostat is satisfied.

NOTE: PHD60 TWO-STAGE COOLING

If the room temperature is 4°F higher than thermostat

setpoint, the indoor fan will run at high speed, and the

compressor at full load. If the room temperature is within

2°F of thermostat setpoint; the indoor fan will shift to low

speed and the compressor will unload to a lower capacity.

4. The compressor and outdoor fan will be de-energized when

the thermostat opens.

5. The indoor fan continues to run for approximately 60 seconds

after the thermostat is satisfied. This allows additional cooling

from the indoor coil to be transferred to the conditioned

space. Then, the indoor fan stops.

STARTUP AND ADJUSTMENT

WARNING

T

O PREVENT PERSONAL INJURY OR DEATH, ALWAYS DISCONNECT THE

ELECTRICAL POWER BEFORE INSPECTING OR SERVICING THE UNIT.

S

INCE ALL

OF THE COMPRESSOR PROTECTION DEVICES RESET AUTOMATICALLY,

THE CONTACTOR AND OUTDOOR FAN MAY BE ENERGIZED WHEN RESET.

WARNING

T

HIS UNIT MUST NOT BE USED AS A "CONSTRUCTION HEATER" DURING THE

FINISHING PHASES OF CONSTRUCTION ON A NEW STRUCTURE.

T

HIS TYPE OF

USE MAY RESULT IN PREMATURE FAILURE OF THE UNIT DUE TO EXTREMELY

LOW RETURN AIR TERMPERATURES AND EXPOSURE TO CORROSIVE OR VERY

DIRTY ATMOSPHERES.

COMPRESSOR PROTECTION DEVICES

This package heat pump unit compressor includes components which

are designed to protect the compressor against abnormal operating

conditions.

OPERATING INSTRUCTIONS

1. Turn ON the electrical power supply to the unit.

2. Place the room thermostat selector switch in the COOL or

HEAT position (or AUTO if available, and if automatic

changeover from cooling to heating is desired).

3. Set the room thermostat to the desired temperature.

MAINTENANCE

WARNING

T

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRICAL SHOCK,

DISCONNECT ELECTRICAL POWER BEFORE PERFORMAING ANY

MAINTENANCE.

REPLACING OR CLEANING FILTER

A return air filter is not supplied with this unit; however, there must be

a means of filtering all of the return air. The filter(s) may be located in

the return air duct(s), or return air filter grille(s). Consult with your

installing dealer for the actual location of the return air filter(s) for

your unit.

Dirty filters are the most common cause of inadequate heating or

cooling performance. Filter inspection should be made at least ev-

ery two months; more often if necessary because of local conditions

and usage.

Dirty throwaway filters should be discarded and replaced with a new,

clean filter. Dirty permanent filters should be washed with water, thor-

oughly dried and sprayed with a filter adhesive before being rein-

stalled. (Filter adhesives may be found at many hardware stores.)

Permanent filters should last several years; however, should one

become torn or uncleanable, it should be replaced.

MAINTAINING CABINET FINISH

Use a fine grade automotive wax on the cabinet finish to maintain

the finish’s original high luster. This is especially important in areas

with high ultraviolet radiation.

CLEAN OUTSIDE COIL (QUALIFIED SERVICER ONLY)

The coil with the outside air flowing over it should be inspected an-

nually and cleaned as frequently as necessary to keep the finned

areas free of lint, hair and debris.

CONDENSER AND EVAPORATOR MOTORS

Bearings on the evaporator motor and the condenser motor are per-

manently lubricated. No additional oiling is required.

WARNING

T

O AVOID PERSONAL INJURY OR DEATH DUE TO ELECTRIC SHOCK, DO NOT

REMOVE ANY INTERNAL COMPARTMENT COVERS OR ATTEMPT ANY

ADJUSTMENT.

CAUTION

A

LWAYS VERIFY PROPER OPERATION AFTER SERVICING.