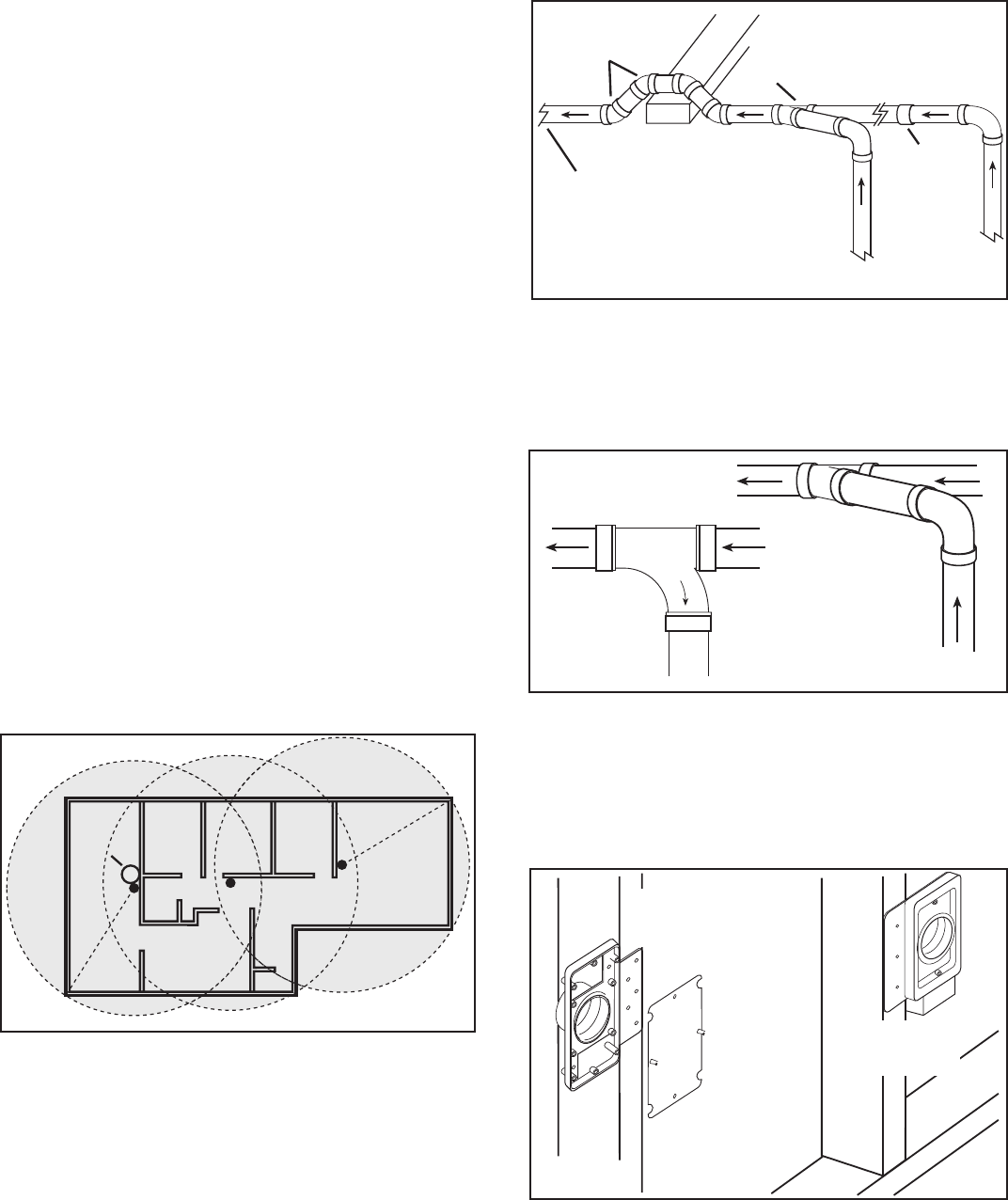

2. Branch lines join the remaining inlets to the trunk line and can be run through

walls, closets, cold air return duct, etc. As with the trunk line, branch lines

should be kept at straight as possible.

3. Avoid gravity drops in the branch line. A branch line located directly below

an overhead trunk line will accumulate dirt due to the effects of gravity. The

result will be a pile of debris at the base of the inlet valve each time it is

opened (Figure 3).

CAUTION: MAKE SURE TUBING WILL NOT OBSTRUCT OR INTERFERE

WITH ELECTRICAL, PLUMBING, OR OTHER MECHANICAL INSTALLATIONS.

Installation into New Construction

Installing the Inlet Valves

1. Using flush mounting screws (not provided) install the appropriate inlet

mounting plate to the wall stud (Figure 4).

NOTE: Installation height will depend on personal preference, but generally the

inlet is installed 18" above the finished floor.

2. To protect the system during the drywall phase of construction, an optional

CVIV80 plaster guard can be utilized and should be installed at this point.

Obstruction

Trunk Line

Branch

Line

45° Elbows

45° Wye

Stop

Coupling

Trunk Line to

Power Unit

Trunk Line to

last Inlet

Wrong

Correct

Debris

Model CVIV70

Standard Inlet

Mounting Plate

Model CVIV80

Plaster Guard

Model CVIV65

Electric Inlet

Mounting Plate

INSTALLATION INSTRUCTIONS

1. Unpack central vacuum power unit from the carton and confirm that all

pieces are present. In addition to the power unit you should have:

1 - Power unit mounting bracket

1 - Inlet valve

1 - Instruction/Safety Sheet

Planning the Installation

The Air King Central Vacuum System consists of three major components. The

power unit, fittings including the inlet valves and tubing, and the tool kit. The

power unit is designed to be permanently mounted in one location with

connections made to the living area with a network of inlets and tubing.

Locating the Power Unit

1. The power unit can be located in a garage, basement, utility room, or any

other room that allows for sufficient ventilation, is dry, and provides

accessibility to the unit for emptying the collection canister.

CAUTION: IF THE POWER UNIT IS INSTALLED IN A CLOSET OR

UTILITY ROOM, IT MUST BE VENTED TO PROVIDE ENOUGH AIR FLOW.

LOUVERED DOORS CAN BE USED. DO NOT MOUNT IN A HIGH AMBIENT

TEMPERATURE AREA SUCH AS ATTIC, FURNACE ROOM, ETC.

NOTE: If venting the unit to the outdoors, avoid venting to areas such as patios

or entranceways.

2. The power unit should be mounted within 5 feet of an acceptable outlet.

Check the electrical specifications of your specific unit to ensure the circuit

is not being overloaded. A dedicated 15 amp circuit should be used.

Locating the Inlet Valves

1. The number of inlet valves will be determined by the layout of your home.

The hose must be able to reach every corner of the home including inside

closets and around furniture. Inlets should be placed in central locations

and avoid placing behind furniture or doors.

2. Using a 30 foot piece of string or the hose itself, have one person hold one

end to the planned inlet location and have the second person walk around

the room(s) to determine if more inlets are needed. Continue this exercise

until you can reach every area of the home (Figure 1).

3. If the installation is for new constructions and you are working with 1/4"

scale blueprints, use a seven inch string to represent the hose.

NOTE: If an electrical tool kit with a corded hose will be used, make sure an

electrical outlet is located within 5 feet of the inlet.

Planning the Tubing System

1. The tubing system will include a main trunk line that will flow from the

furthest wall inlet back to the power unit and can be run through the

basement or the attic (Figure 2). The trunk line should be kept as straight

as possible to maximize the unit performance. When elbows are needed

45° fittings should be used or if a 90° connection is required, a sweep elbow

should be used.

Figure 1

Living

Room

Bedrm

Garage

Kitchen

Hall

Power

Unit

Bath

Bedrm Bedrm

000000 Rev A. 3-05

www.airkinglimited.com

2 of 16

Figure 2

Figure 3

Figure 4