035-16328-002Rev.C(0902)

RETURN AIR REQUIREMENTS

CLOSET INSTALLATIONS

Additional Requirements

Additionalrequirements for floorand ceiling returnsystem for

closet installed sealed combustion heating appliance are

given in the next paragraph.

Floor or Ceiling Return Air System

Listed in the next paragraph are the conditions to be met by

Manufactured Home Manufacturers to have U.L. acceptance

of in-floor or ceiling return air systems of closet installed

direct vent forced air heating appliances for Manufactured

Homes to be sold in the United States.

1. The return-air opening into the closet, regardless of loca-

tion, is to be sized not less than specified on the appli-

ance's rating plate.

2.

3.

4.

5.

If the return-air opening is located in the floor of the

closet (versus the verticalfront or side wail), the opening

is to be provided with means to prevent its inadvertent

closureby a fiat objectplacad over the opening.

The cross-sectional area of the return duct system (when

located in the floor or ceiling of the manufactured home)

leading into the closet is to be not less than that of the

opening specified on the appliance's rating plate.

The total free area of openings in the floor or ceiling reg-

isters servingthe return-air duct system is to be not less

than 150% of the size of the opening specified on the

appliance's rating plate. At least one such register is to

be located where likelihood of its being covered by car-

peting, boxes, and other objects is minimized.

Materials located in the return duct system have a flame

spread classification of 200 or less.

6.

7.

8.

9.

10.

Non-combustiblepans having one-inch upturned flanges

are located beneath openings in the floor return duct

system.

Wiring materials located in the return duct system con-

form to Article 300-22 (B&C) of the National Electrical

Code (NFPA-70).

Gas piping is not run in or through the return duct sys-

tem.

The negative pressure in the closet as determined by

test with the air-circulating fan operating at high heating

speed and the closet door closed is to be not more nega-

tive than minus 0.05-inch water column.

For floorreturn systems, the manufactured home manu-

facturer or installer shall affix a prominent marking on or

near the appliance where it is easily read when the

ctoset door isopen. The marking shall read:

_WARNING

HAZARD OF ASPHYXIATION, DO NOT COVER

OR RESTRICT FLOOR OPENING

AIR DISTRIBUTION SYSTEMS

For proper air distribution, the supply duct system shall be

designed so that the static pressure does not exceed the

listed static pressure rating on the furnace rating plate.

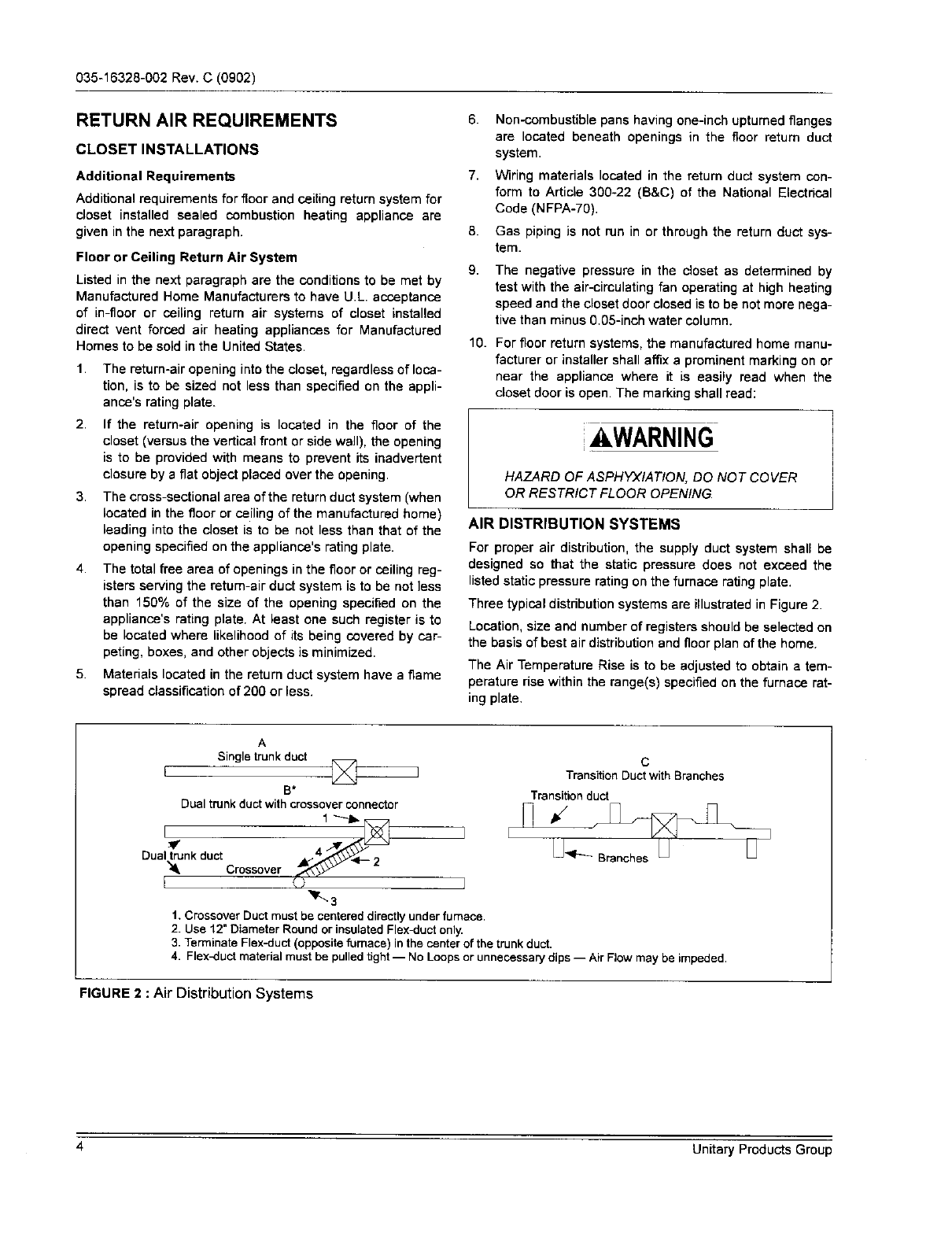

Three typicaldistdbution systems are illustratedin Figure 2.

Location, size and number of registers should be selected on

the basis of best air distribution and floor plan of the home.

The Air Temperature Rise is to be adjusted to obtain a tem-

perature dse within the range(s) specified on the furnace rat-

ing plate.

A

Singletrunkduct _ C

E

TransitionDuctwithBranches

B*

Dualtrunkductwith crossoverconnector

Dualtrunk duct

Crossover

I

_r-..3

1.CrossoverDuctmust becentereddirectlyunderfurnace.

2. Use 12"DiameterRoundor insulatedFlex-ductonly.

3. TerminateFlex-duct(oppositefurnace)in the centerofthe trunkduct.

4. Flex_uct matedalmustbepulledtight-- No Loopsor unnecessarydips-- AirFlowmay beimpeded.

Transitionduct

FIGURE 2 : Air Distribution Systems

4 Unitary Products Group