20 Dealer Service

MAN0661 (8/10/2007)

DEALER SERVICE

The information in this section is written for dealer ser-

vice personnel. The repair described here requires

special skills and tools. If your shop is not properly

equipped or your mechanics are not properly trained in

this type of repair, you may be time and money ahead

to replace complete assemblies.

NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equipment

or between moveable parts even when the engine

has been turned off. Hydraulic system leak-down,

hydraulic system failures, mechanical failures, or

movement of control levers can cause equipment

to drop or rotate unexpectedly and cause severe

injury or death.

• Service work does not require going under-

neath.

• Read Operator's Manual for service instruc-

tions or have service performed by a qualified

dealer.

Do not allow bystanders in the area when oper-

ating, attaching, removing, assembling, or servic-

ing equipment.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its compo-

nents in any way.

Do not disconnect hydraulic lines until machine

is securely blocked or placed in lowest position

and system pressure is released by operating

valve levers.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

REPLACE BRUSH SECTIONS

1. Remove motor mount screws. Retain hardware for

reinstallation. Remove motor mount.

2. Remove bearing mounting plate screws from side.

Retain hardware for reinstallation.

3. Remove the side flaps. Retain hardware for

reinstallation.

4. Lift sweeper body leaving core on ground.

5. Remove the bearing mounting plate and section

retainer plate. Retain hardware for reinstallation.

6. Remove old sections.

Install New Sections

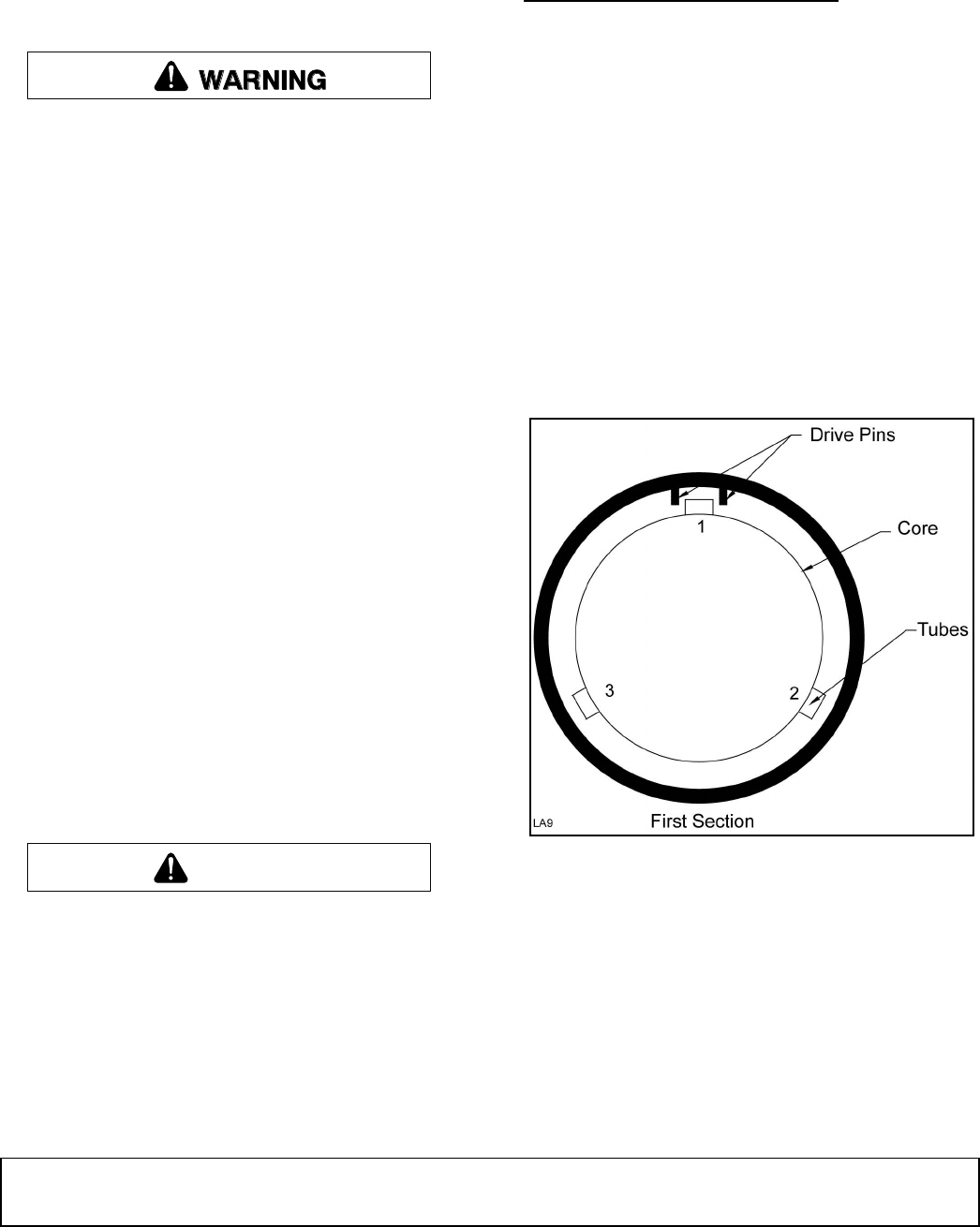

1. Number the tubes on the core as 1, 2 and 3. See

Figure 13.

Figure 13. Number Tubes

2. Slide the first section onto the core with the drive

pins on either side of tube 1. Make sure that the

drive pins angle upward (Figure 13).

CAUTION