NOTE:

If

powdered

soap

is

used.

premix with

hot

water before

fiOing salulion

tank.

A.

Reinstall

recovery

tank and dome.

Make

sure

hoses

are

snug

h

he

donre.

OPERATING THE

PASSPORT

-

WARNING

Read the IMPORTANT

SAFETY

INSTRUC

-

TIONS before

operating,

paying parfcular

attention to

care

and

use

of

the

power supfly

cord.

Only

operate

if

the

cord

is

in

perfect

condition.

NOTE: Vacuum

che

carpet

and make

sure

it is

dmred

of

surface

debrk before cleaning.

I.

Attxh

straln

relieflcotd

n36ine1

to

power

cord. Make bop

in

power

ad

approxi-

matety

\

T

Prom

recephcle

end.

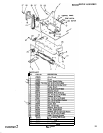

(DIAGRAM A.

)

2.

Adjust brush height by turning knob

at

front

of

machine. Pointer

on

left

side

indicates carpet

height.

LOW

-

114

inch

ME0

-

112inch

HIGH

-

1

+ih

NOTE: lrPcouett move height

may

cause

brush circuit breaker

to

kip.

Raise

brush

and

reset circuit breaker.

3.

Turn

sokrUon

valve

to

'CARPET CLEAN

-

ING' position.

(DIAGRAM

8)

outlet

DUGRAM

C:

switch.

!%??

4.

Plug power

cord

into

a

grounded wall

5.

Turn

on

he

vacuum switch and brush

NOTE:

Excessbe

water

andlor

loam

h

the

re

cwery

tank may cause water andlor foam

to

enter

the

vacuum

motw.

This

andition

will

over

-

bad

the

vacuum motor and

the

vacuum circuit

breaker

will

trip.

6.

Depress

intermittent pump

switch

to

dispense

cleaning

solution.

Puil

machine

backwards.

Release

pump switch about

12

inches

before

the end

ol

each cleaning

pass.

TMa

will ensure

all

deanhg

solution

k

vacuumed from carpet.

CAUTION:

While

operating machine, check

for

excessive

foam

buld-up

in

the

recwecy

tank.

If

excessive

foam

is

present,

add

a defoamer solutlon

to

re-

covecy tank

7.

Empty

recovery

tank when approximately

YA

full.

CAUTION

:

DO

not

use

me

reeovwy tank to

CII

the

sorution

tank. unless it

is

CLEAN. Sediment

in

the remv-

ery

tank cnn damage

the

sobtion

pump

and

dog

he

spray

jets

rendering

dre

machine inoprable.

TM

PASSPOR

T

-

I

ACCESSORY TOOLS

The

PASSPORT

is

easily

adapted

for

use

wich

the

following

Wlnhor

access- took:

DHT

,

SW,

SFW,

SWPRO.

WARNING

Never

operate acces-

soty

took

with

water temperaNre abwe

509

C.

1.

Turn

solution

valve

to

'ACCESSORY

TOOL

-

position

(DIAGRAM

6)

dome

and

insert

vacuum hose

from

accessory

tool

in

its place.

3.

Attach

sdulton

hose

from

accessory

tod

to

brass quick

dlsmnect fitting on

left

side

of

machine.

2.

Remove

recovery

hose (white

cull)

from

4.

Remove

dome

and

recovery

bnk.

5.

Fill

soluljon

tank with

deaning

concentram

per

manu

facurer's recommendation.

6.

Install

rwovely

tank

and

dome.

7.

Turn

on

vacuum and continuous pump

switches only.

CAUTION:

Do

not

Urn

on

brush switch.

Damage

to

carpel could ocwr.

DAILYREGULAR

w;*:zE

Before making

any

adjustments

or

repairs

to

he

machine, disconnect

the

power

cord

from

elec!riwl

sourco.

1.

Emply

unused cleaning solution.

2.

Inspect and

clean

solution

filter

screen.

3.

flush pumping

system

with

1

to

2

gallons

4.

Rinse

recovery

lank

with

dean

water.

5.

RemsJe

any lint

or

debris

around

brush

and

vac shoe.

6.

Check

spray

jets

and dean solenoid

vahre

if

required.

NOTE: Always

store

machine

wih

brush

in

'store'

position.

of

dean

hot

water.

PERIODIC MAINTENANCE

salu(i0n

(me

quart

vinegar

to

one

gallon

of

hot water)

or

an

anU-browning

sdution

(mixed

as

dwecred)

through

the

extractor.

This

will

help

prevent

build

-

up

of

alkaline

residue

in

system.

2.

If

spray

je6

become clogged,

remove

the

spray tips, wash

them

thoroughly

in

vinegar

and

blow dry.

1.

Twice

a

monm

flush

a white vinegar

NOTE:

Do

not

use

pins, wires. etc. lo clnan

jets

as

this

will

destroy spray pattefn.

3.

II

spray jets continue

to

drip alter punip

is

turned

off.

the solenoid valve

will

need

cleaning.

(See

MAINTENANCE

Instructions

Rev.1

5/2/94

cables.

Rlters

and connecuons

on

your

machine.

Frayed

or cracked

hoses

should

be

repaired

or

rsplaced

to

eliminate vacuum

or

solution

pressure

loss.

Because

thq

electrical

cable

will

lie

on

wet

carpet

a1

times.

Ole

cable

must

be

well

insulated

and

cable

connector

screws

kept Tght.

If

the

cable

insulation

is

broken

or

bayed. repair

or

replace

it

immediately.

Don1

take

chances

with

an

electriGiI

rue

or

shock

PROTECT FROM

FREEZING

If

it

becomes

necessary

lo

store

dr@rnachine

in

temperalures below

4

"

C

the

pumping sys:eni,

vabes.

eb.

must

be

protected

horn

(rearing

with

a methyl hydrate (window washer) antifreeze

sofution.

NOTE:

Do

not

use

eUiy{nne

glyml

or

cooling

system antifreeze.

1.

Add

window washer

nnofreero

to

the

solulon

tank.

2.

Turn

on

pump

unol

solutionsprays

cv:

zf

3.

Remove unused portion

of

antifreeze

@S.

from

tank

MAINTENANCE

INSTRUCTIONS

-

WARNING

1.

Only

qualified maintenance personnel are

to

perform

che

following repairs.

repairs.

connections.

2.

Unplug

(he

machine

belore

attemptina

.my

3.

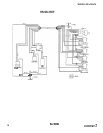

Reler

to

wirlng diagram

lor

proper ei%fric;II

BRUSH ASSEMBLY

1.

Remove belt guard, brush pulley guard

and bearing

covers a1

each

end

of

brush

2

Loosen

(2)

hex

nuts

on

moor

studs

and

rotale

motor dawnwards and remove beit

from

motor pulley.

3.

Remove

brush

assembly

from

.

.

Replace brush

or

bearings

as

required.

proper tension.

&it

should

be

taught

(Do

not

overtighten.)

To

ndjust

belt.

lmseir

i2)

hex

nuts,

rotate

molor

rearward anu

retighten

nuts.

4.

When re.inslalng brush, check belt

:or

ro

ACCESS

CHASSIS

COMPONENTS

1.

Lilt

off

recovery tank

and

set

.aside

2.

Reme

solution

-

drain

hose

lrom

3.

Remove

(A)

bolts holding lank to

cn%x

4.

Raise tank

and

pull soiulim

drain

hose

hosebarb

through chassis.

Remove

pump

Inlot

hose

torn

rank and tay

tmk

aside

3