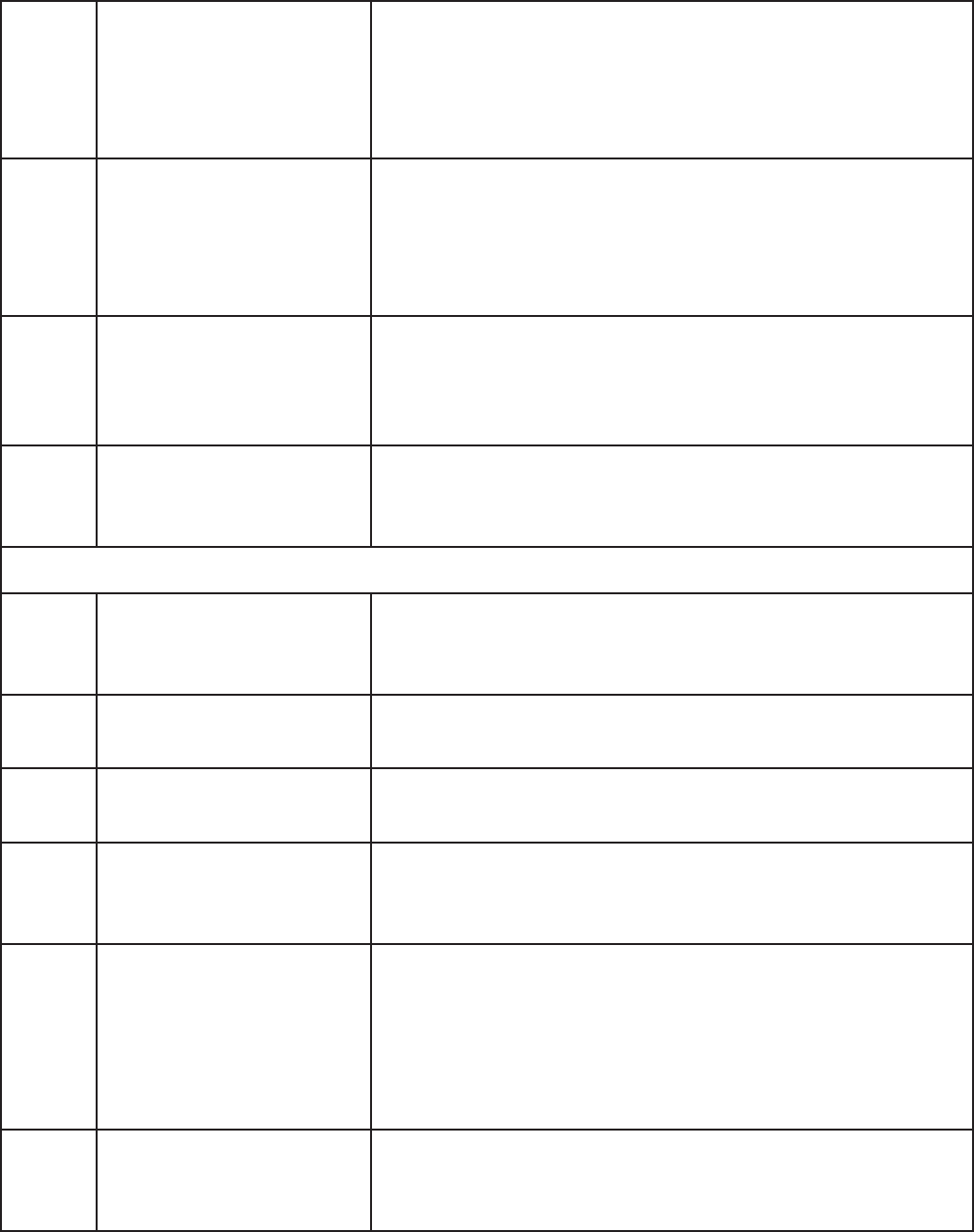

7. System low on

refrigerant.

Checkrefrigerant“sightglass”in1/4”tubing.

Check for bubbles after system has run for several

minutes. If bubbles present, call a CERTIFIED HVAC

service technician. If sight is clear of bubbles,

refrigerant level is OK.

8. Thermostatic

expansion valve power

element losing its

charge.

System will operate as if it were low on refrigerant

charge. Sight glass will be clear. Evaporator coil icing

probable.

Call a CERTIFIED HVAC service technician.

9. Low voltage to

compressor, below

103V with compressor

running.

Low voltage will cause compressor overheating and

tripping on overload. Also, can have difficulty starting.

This is usually a field wiring problem which should be

corrected immediately.

10. Cooling system not

sufficient for load

If system is determined to run OK but not keeping up,

run a heat gain calculation for the wine cellar and

compare with cooling system capacity.

Evaporator blower runs, but compressor does not

1. System “Anti-Frost“ Observe for several minutes. Compressor should turn on

at termination of “Anti Frost“ Cycle and evaporator clear

of frost.

2. Power off to

compressor.

Checkbreaker/Referto#3above

3. Out of refrigerant. Call a CERTIFIED HVAC service technician to locate leak,

repair and charge with refrigerant

4. Compressor off on

overload.

Determine if compressor is hot. If not, there is another

problem. If yes, shut off power to condensing unit and

call service technician

5. Liquid line solenoid

valve in evaporator not

active.

Remove cover. Locate valve in ¼” copper tube. Check

to see if it is hot. If hot and you can feel a magnetic pull

with a screwdriver, the valve is working. If cold, there is

no power to the valve coil. In this event, with the blower

running, the valve should be powered. Call a CERTIFIED

HVAC service technician.

6. Thermostat

expansion valve power

element lost charge

System will “pump down.” Compressor will stop.

May start occasionally and shut off quickly.

Call a CERTIFIED HVAC service technician.

-25-