6

LGB-6 to LGB-23

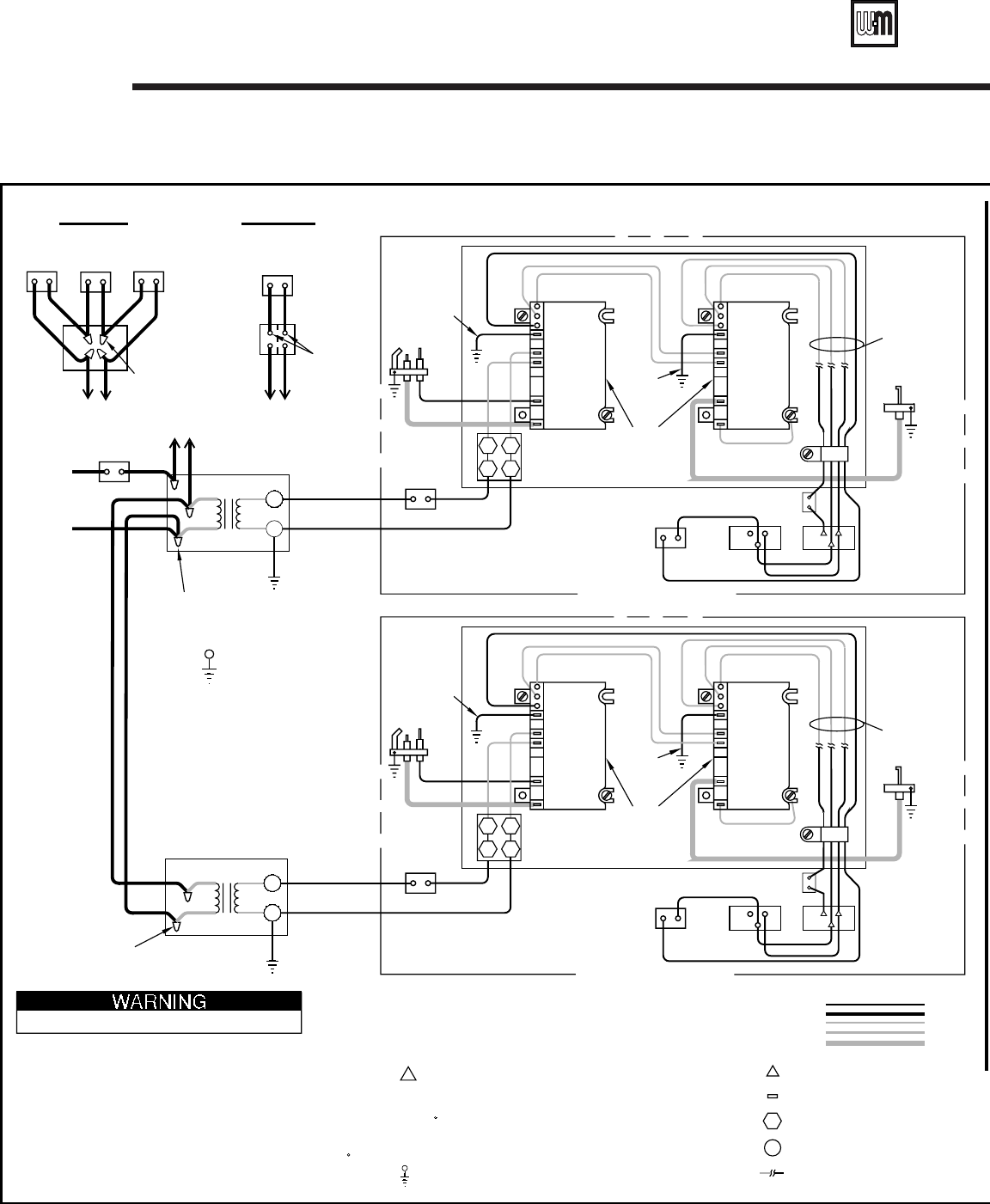

Series 2 – Control Supplement

Part Number 550-141-916/1001

9. PILOT LEADWIRES ARE NOT FIELD REPLACEABLE. REPLACE PILOT ASSEMBLY IF NECESSARY.

IF ORIGINAL GROUND LEADWIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED,

B. CANADA - C.S.A. C22.1 C.E.C. PART 1.

A. U.S.A. - N.E.C. CLASS 1.

2. ALL WIRING EXTERNAL TO BOILER JACKET MUST BE:

B. CANADA - C.S.A. C22.1 CANADIAN ELECTRICAL CODE PART 1 AND ANY OTHER

CODE REQUIREMENTS.

1. ALL WIRING MUST BE INSTALLED IN ACCORDANCE WITH:

ELECTRICAL SHOCK HAZARD, CAN CAUSE SEVERE INJURY OR DEATH.

DISCONNECT POWER BEFORE INSTALLING AND/OR SERVICING.

4. REFER TO CONTROL COMPONENT INSTRUCTIONS PACKED WITH BOILER FOR

ITS EQUIVALENT MUST BE USED. EXCEPTION, SEE NOTE 7.

APPLICATION INFORMATION.

3. IF ORIGINAL WIRE AS SUPPLIED WITH THE APPLIANCE MUST BE REPLACED, TYPE 105 C OR

NATIONAL, PROVINCIAL, OR LOCAL CODE REQUIREMENTS.

A. U.S.A. - NATIONAL ELECTRICAL CODE AND ANY OTHER NATIONAL, STATE, OR LOCAL

NOTES:

FOR LOW AND HIGH FIRE OPERATORS.

TYPE 125 C OR ITS EQUIVALENT MUST BE USED.

5. STANDARD EQUIPMENT FOR LGB-21 THRU LGB-23.

10. DENOTES FIELD INSTALLED CHASSIS GROUND.

6. TERMINAL ON MAIN GAS VALVE IS A SINGLE TERMINAL (COMMON)

7. REFER TO CONTROL SUPPLEMENT FOR GROUND LEADWIRE ATTACHMENT.

8. WIRES ARE FACTORY INSTALLED TO CONTROL PANEL, BUT MUST BE FIELD

CONNECTED TO GAS VALVES AND FIRING RATE CONTROL TERMINALS (WHEN USED).

11. ALL CONTACTS SHOWN WITHOUT POWER APPLIED - OFF SHELF CONDITION.

HIGH VOLTAGE FACTORY

IGNITION/SENSING CABLE

HIGH VOLTAGE FIELD

LOW VOLTAGE FACTORY

LOW VOLTAGE FIELD

FIELD WIRED TO GAS

CONTROL MODULE TERMINAL.

TRANSFORMER TERMINAL.

IGNITION CONTROL

VALVE OR FIRING RATE CONTROL.

MAIN GAS VALVE TERMINAL.

FIRING RATE CONTROL

(WHEN USED)

FIRING RATE CONTROL

NO. 1 BASE WIRING

WIRE NUTS (2)

TRANSFORMER

(SIZES 13 THRU 23)

NO. 2 BASE WIRING

(NOTE 5)

SWITCH

PRESSURE

(WHEN USED)

HIGH GAS

V.A.C.

W

120

V.A.C.

24

BK

C

R

GROUND

(NOTE 10)

EQUIPMENT

WIRE NUTS (3)

(NOTE 7)

PILOT

PRE-WIRED PANEL

(NOTE 9)

BLOCK

TERMINAL

PILOT SOLENOID

VALVE

SPARK

UNIVERSAL

CONTROL

IGNITION

G

(NOTE 7)

G

(SIZES 6 THRU 23)

CUT-OFF

LOW WATER

(BY OTHERS)

SERVICE SWITCH

FROM TRANSFORMER

LIMIT CIRCUIT

STEAM

DISCONNECT

N

FROM

FUSED

H

JUNCTION

BOX

CONTROL

OPERATING

SWITCH

(NOTE 5)

HIGH GAS

PRESSURE

(WHEN USED)

TRANSFORMER

V.A.C.

24

W

V.A.C.

120

TO LIMIT CIRCUIT

BK

C

R

LOW WATER

OPERATING/LIMIT

FROM TRANSFORMER

WIRE NUTS (4)

CONTROL

COMBINATION

CONTROL

LIMIT

TEMPERATURE

NOT USED

WHEN L.W.C.O. IS

TO BE JUMPERED

THESE TERMINALS

CUT-OFF

PRE-WIRED PANEL

1

2

TERMINAL

BLOCK

PILOT SOLENOID

VALVE

SPARK

IGNITION

CONTROL

UNIVERSAL

MODULE

PILOT PROVING

G

PILOT

(NOTE 9)

(NOTE 7)

(NOTE 7)

G

SCHEMATIC WIRING DIAGRAM

LIMIT CIRCUIT

WATER

HIGH

MAIN FLAME

SENSOR

STAGE COMBINATION

MAIN GAS VALVE - TWO

VALVE W/REGULATOR

(WHEN USED)

R

BL

W

WIRE TIE CLIP

(NOTE 8)

MAIN FLAME

SENSOR

STAGE COMBINATION

VALVE W/REGULATOR

MAIN GAS VALVE - TWO

BL

W

R

WIRE TIE CLIP

(NOTE 8)

2

1

SPARK

MV/PV

(BURNER)

24V (GND)

24V

SENSE

GND

PV

MAIN FLAME

PROVING MODULE

MV

SENSE

SPARK

MV

MV/PV

GND

24V

24V (GND)

PV

(BURNER)

SPARK

MV/PV

(BURNER)

24V (GND)

24V

SENSE

GND

PV

MAIN FLAME

PROVING MODULE

MV

SENSE

SPARK

MV

MV/PV

GND

24V

24V (GND)

PV

(BURNER)

MODULE

PILOT PROVING

MV/PV

PV

MV

MV/PV

PV

MV

MV/PV

WBL

WBL

MV/PV

MV

PV

SECONDARY

GAS VALVE

BK

BK

WBL

WBL

MV/PV

MV

PV

SECONDARY

GAS VALVE

BK

BK

FACTORY WIRED TO CONTROL -

PANEL TERMINAL.

III Wiring – continued