3

BMC and BMC-6X Installation and Operation Manual

BMC

SYSTEM

A

B

C

D

Full Modulation Sequencing Control

1

2

RUNPROGRAM

FOR ALL CIRCUITS

120VAC, 6A RESISTIVE

OUTPUT RATINGS:

1A PILOT DUTY, 15A TOTAL

115VAC 60Hz , 30VA MAX

INPUT RATINGS:

USE COPPER WIRE,

DO NOT APPLY ANY VOLTAGE

TO INPUT TERMINALS

3

4

5

6

7

8

9

10

11

12

13

15

14

17

16

18

22

20

19

21

24

23

29

25

27

26

28

32

30

31

L

N

-

+

+

T

T

O

O

RS-485

mA

GND

VLT

SYS

A

B

C

D

PWR

CUR / VLT

A

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

-

+

+

mA

GND

VLT

+

mA

TEMP

OUTDOOR

O

O

TEMP

SYSTEM

EXTENSION

MODULE

CUR / VLT

B

CUR / VLT

C

CUR / VLT

D

CLASS 1 WIRE ONLY.

------

SYSTEM

PROVE

SHUTDO

W

N

/TSTAT

/SETBACK

ENCLOSED

ENERGY

MANAGEMENT

EQUIPMENT

LISTED

99RA

CAUTION: RISK OF ELECTRIC SHOCK

More than one disconnect switch may be required

to de-energize the equipment before servicing.

CUS

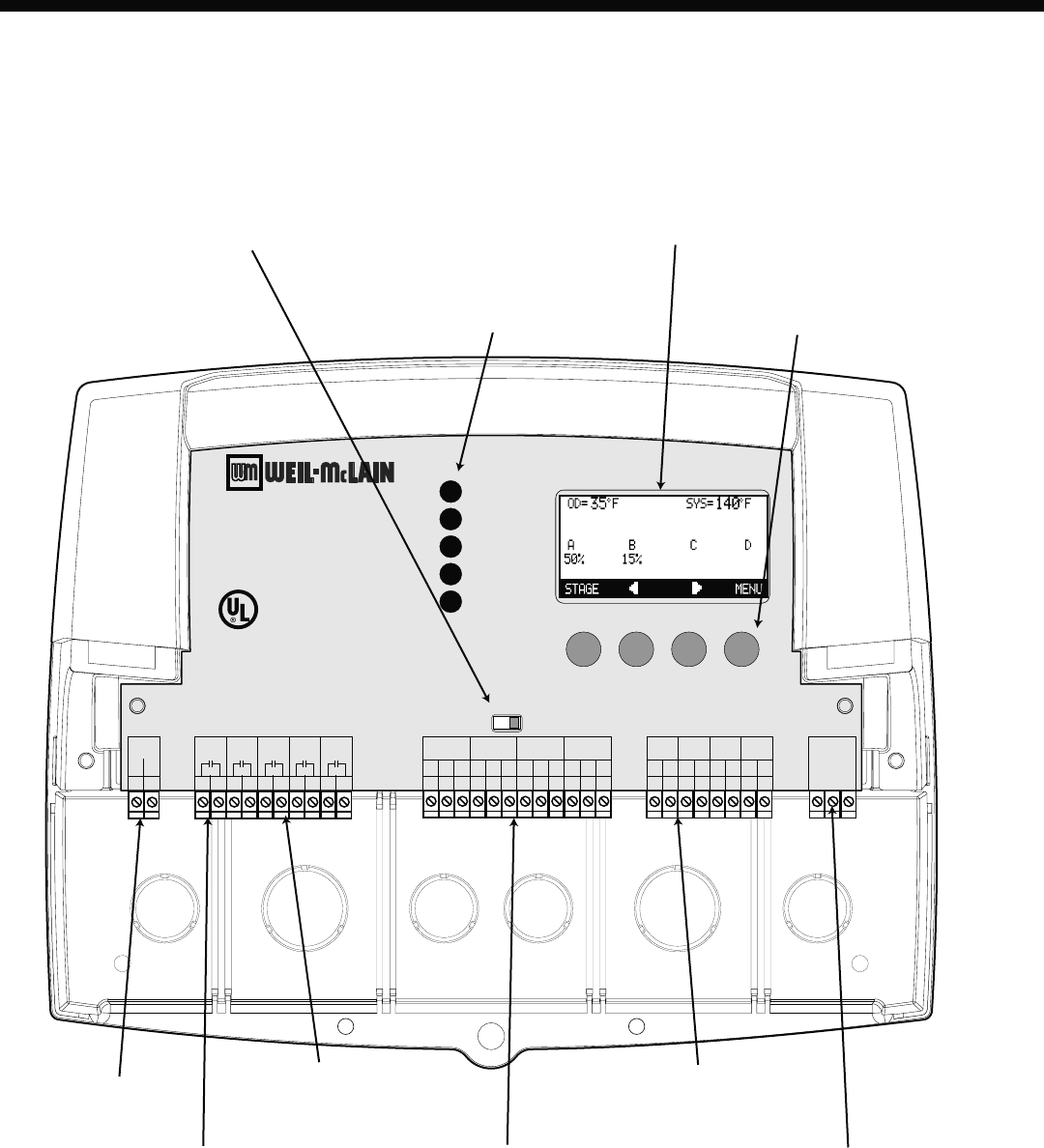

The digital display shows the system status, set point,

lead stage <in brackets>, and status of each stage.

To view and adjust settings, press the appropriate buttons.

120VAC Power

Four N.O. Boiler startup relay

outputs. Each is wired in series

with each boiler's limit circuit.

System Output controls

pumps, valves, or other

system components.

Four modulation outputs can be 0-5V,

0-10V, 1-5V, 2-10V, or 4-20ma. Go to

Startup Menu to determine the type of

output for each stage.

LED indicates the

associated relay status.

Buttons function is presented on

Bottom Row of display.

When connecting Outdoor and System

Sensors, no Polarity is observed.

Prove terminals must be connected

for BMC to operate boilers.

Connect Extension panels to

add additional stages using

a 6 pin phone line only (cable

provided with BMC-6X).

Program Switch to restrict access to

function changes. This switch is

covered with Wiring Enclosure.

BMC LAYOUT