Part number 550-141-396/0801

4

PER Series 3 Electric-Hydronic Boilers Installation Instructions

Piping the boiler

After the boiler is secured to the wall, attach the supply

and return piping. Refer to Table 2 for minimum pipe

sizes.

Install manual shut-off valves in the supply and return

lines to facilitate servicing the boiler. Model PER boilers

are provided with a built-in air elimination system using

a float-type automatic air vent. Refer to the boiler line

drawings and proceed as follows:

1. Install the pressure-temperature gauge and ¾"-¼"

bushing in the 1¼" x 1¼" x ¾" tee installed on the

boiler supply connection. See “Dimensions” on

page 12.

2. The ¾" tapping, located to the left of the supply

tapping, must be used for either an automatic

venting device or piped directly to a standard closed

expansion tank.

3. Install the pressure relief valve in the ¾" tapping

located on the top left hand side of the boiler (see

“Dimensions” on page 12). Pipe the relief valve

outlet to a floor drain or near the floor. Do not pipe

the relief valve to any area where freezing

temperatures might be encountered.

Pipe relief valve discharge line near

floor close to floor drain to eliminate

potential of severe burns. Do not

pipe to any area where freezing

could occur. Do not plug valve or

place any obstruction in discharge

line.

4. Connect the system supply piping to the tapping

located at the right on the top of the boiler casting.

5. Connect the system return piping to the circulator

flange. When solder fittings are used, be sure that

the gasket is not between the flanges when the solder

connection is made.

6. A Fill-Trol system is supplied with PER boilers

follow the instructions attached to the valve.

Pre-installation continued

Wiring the boiler

Electric shock hazard. Can cause

severe personal injury or death if

power source, including service

switch on boiler, is not disconnected

before installing or servicing.

The Model PER electric-hydronic boilers are pre-wired

for use with 240-volt, single phase, 50/60-hertz power.

Refer to Figure 1 on page 13 for the reduction in boiler

capacity when the line voltage is less than 240 volts.

An opening is provided in the left side of the jacket top

panel for the field wiring. Refer to Dimensions, page

12, and Ratings, page 13, for recommended wire sizes.

All wiring must conform to the requirements of the

National Electrical Code and any additional National,

State or Local Code Requirements having jurisdiction.

All safety circuit wiring should be N.E.C. Class 1. Do

not use aluminum wire.

When a PER boiler is used in a zoned system, the zone

valves must be powered from an independent source,

and have electrically isolated end switches or isolating

relays wired in parallel to the boiler thermostat

terminals.

Do not attempt to power zone valves

from the transformer in the boiler

control system.

Control system

The control system for the PER electric boiler has

electronic and thermal time delays, which are employed

to sequence elements on and to sequence elements off

in reverse order. The contactors used in the system

disconnect all current from the heating elements.

The circulator control utilizes a single pole relay.

Low and high limit functions are combined in a dual

limit control. The control system is operated from a

low voltage transformer.

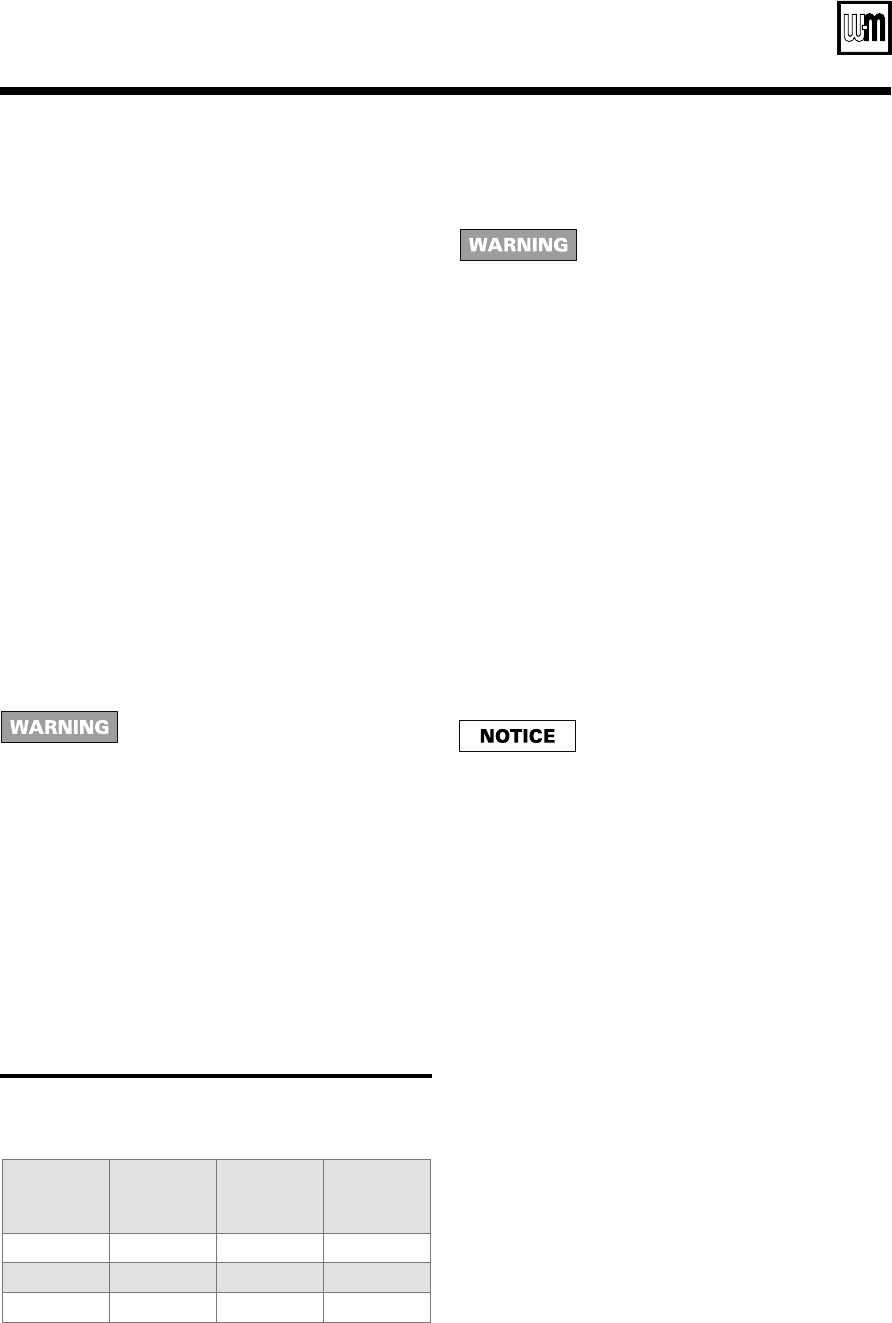

Table 2 Pipe sizes and flow rates

(Recommended minimum pipe size with 20°F

temperature rise through boiler.)

Boiler

model

number

Maximum

flow rate

GPM

Minimum

supply

pipe size

Minimum

return

pipe size

PER-15 5.20 ¾" ¾"

PER-20 6.90 1" 1"

PER-25 8.60 1¼" 1¼"