Part number 550-100-067/0608

7

g a s -f i r e d w a t e r b o i l e r — User’s Information Manual

Maintenance procedures — MONTHLY

Maintenance procedures — PERIODICALLY

Test the low water cutoff (if installed)

If the system is equipped with a low water cutoff, test the low 1.

water cutoff periodically during the heating season. Follow

the low water cutoff manufacturer’s instructions.

Reset the boiler control after testing.2.

Check U-Control date and time

Check the time shown on the U-Control display.1.

If time is incorrect, set the correct date and time as shown 2.

on pages 10 and 11.

Check vent piping

Visually inspect the flue gas vent piping for any signs of block-1.

age, leakage or deterioration of the piping. Notify your quali-

fied service technician at once if you find any problem.

Failure to inspect the vent system as noted above

and have it repaired by a qualifed service technician

can result in vent system failure, causing severe

personal injury or death.

Check air piping

Visually inspect the air inlet to be sure it is unobstructed. 1.

Inspect entire length of air piping to ensure piping is intact

and all joints are properly sealed.

Call your qualified service technician if you notice any 2.

problems.

Check the relief valve

Inspect the boiler relief valve and the relief valve discharge 1.

pipe for signs of weeping or leakage.

If the relief valve often weeps, the expansion tank may not be 2.

working properly. Immediately contact your qualified service

technician to inspect the boiler and system.

Check the condensate drain system

While the boiler is running, check the discharge end of the 1.

condensate drain tubing and the open top of the condensate

tee at the boiler (see Figure 3, page 10 for locations). Make

sure no flue gas is escaping from the condensate drain tubing

or tee by holding your fingers in front of the opening.

If you notice flue gas escaping, this indicates a dry conden-2.

sate drain trap. See step 4 for procedure to fill trap. Call

your qualified service technician to inspect the boiler and

condensate line and refill the condensate trap if problem

persists regularly.

Under some circumstances an Ultra vent system

may not produce enough condensate to keep the

condensate trap full of liquid. If the trap is not full,

small amounts of flue products can be emitted into

the boiler room through the condensate drain line

or tee. Follow procedure below to fill trap.

Verify that the condensate drain line is unobstructed by 3.

slowly pouring water into the top of the PVC tee on the side

of the boiler. The water should run out the end of the con-

densate drain line. If the water does not run out, call your

qualified service technician to inspect the boiler and clean

or replace the condensate drain line.

To fill the condensate trap, if necessary, temporarily plug the 4.

end of the condensate drain line. Then slowly pour water into

the ½ inch plastic tee on boiler right side. Pour until water

fills drain line, then overflows into the boiler trap tubing.

When water fills up to top of ½ inch tee, stop filling. Remove

temporary plug from end of condensate drain line.

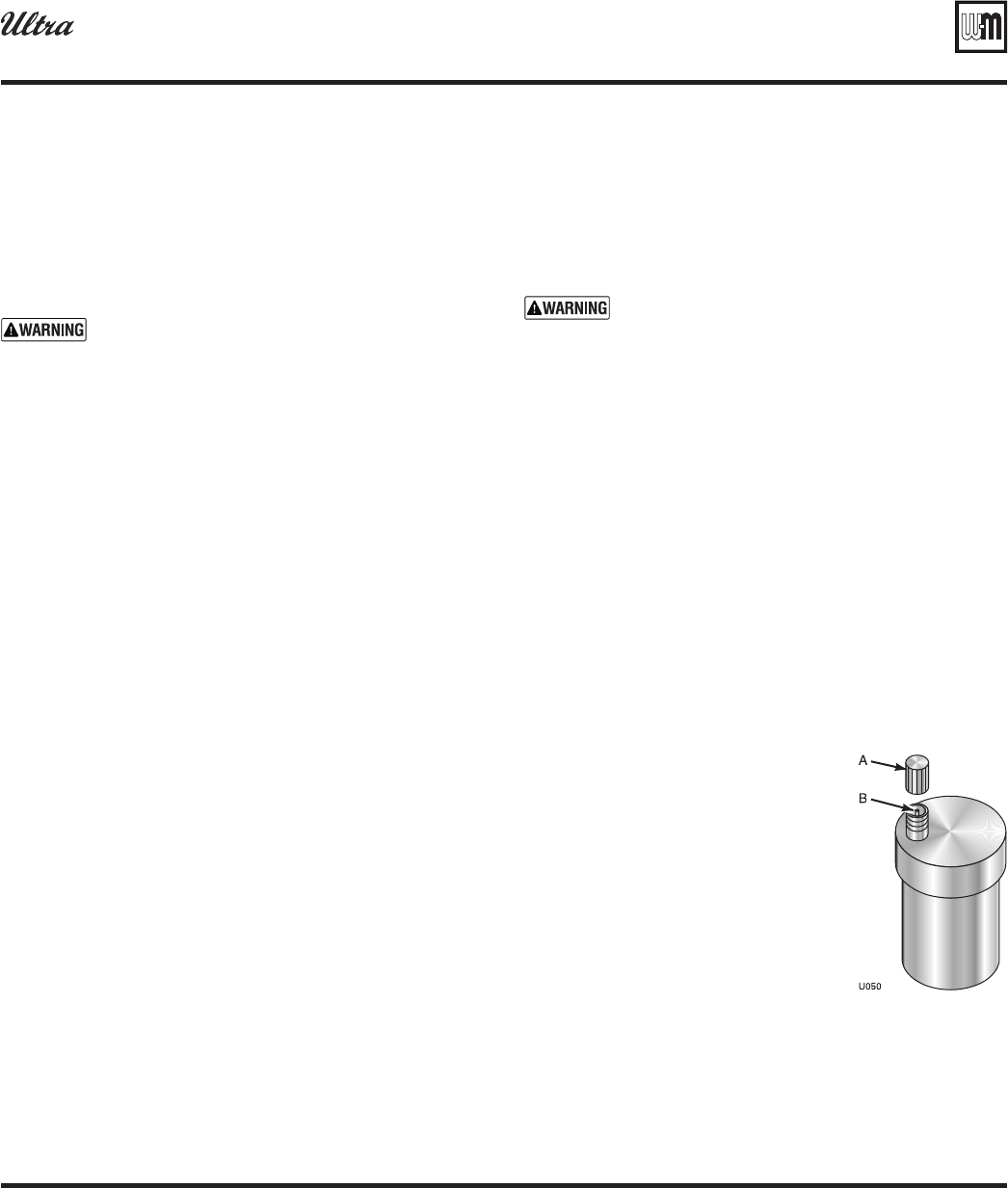

Check automatic air vents (if used)

See illustration at right. 1.

Remove the cap from any automatic 2.

air vent in the system and check oper-

ation by depressing valve “B” slightly

with the tip of a screwdriver.

If the air vent valve appears to be 3.

working freely and not leaking,

replace cap “A”, twisting all the way

on.

Loosen cap “A” one turn to allow vent 4.

to operate.

Have vent replaced if it does not 5.

operate correctly.