idrive™ models: 3660-372, 3661-372, 3662-372,

3760-372, 3751-372.

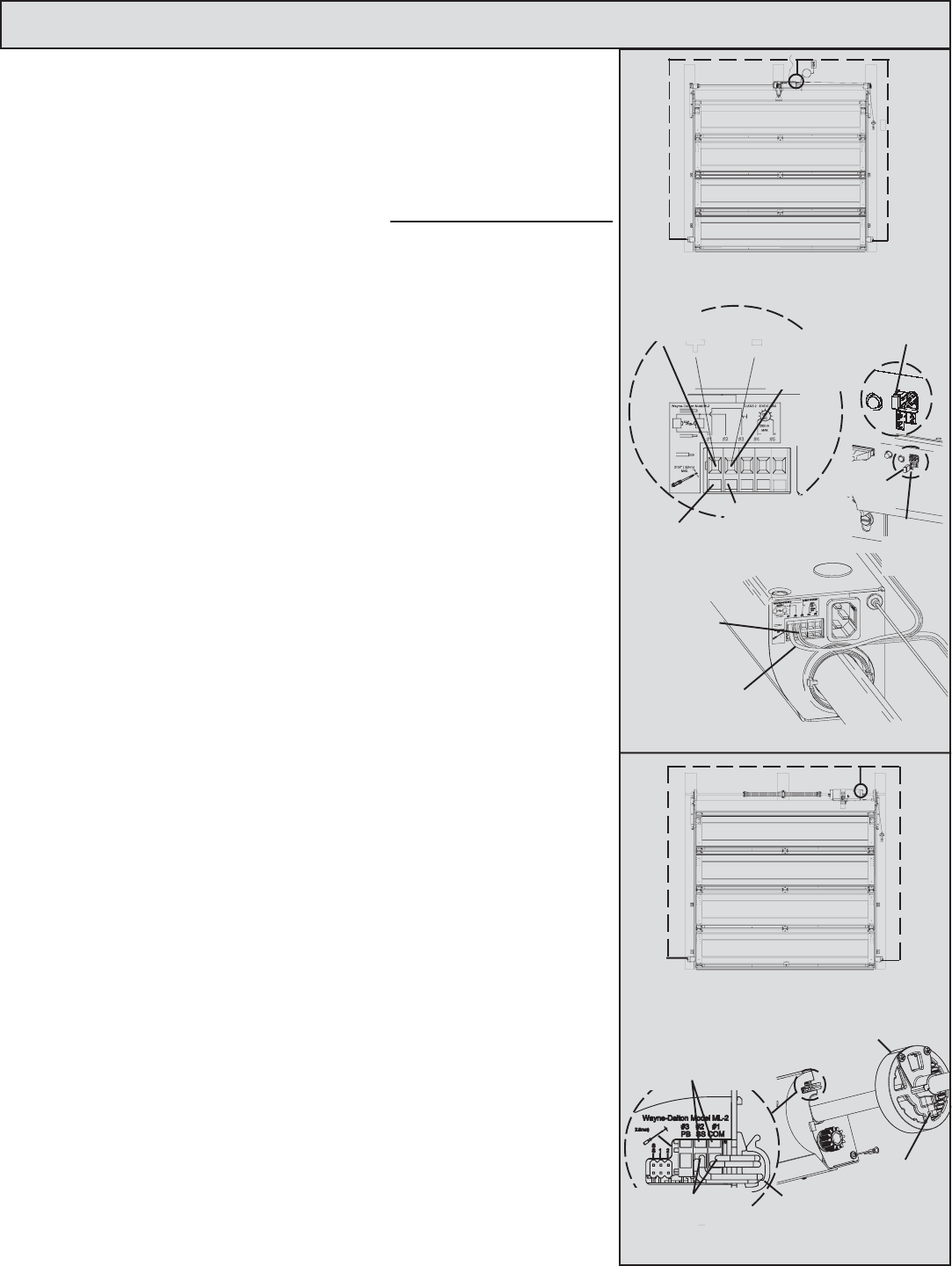

Uncoil wires from photoelectric sensors and route wires up garage wall

and along door header towards the right side of the opener

(see Fig. 3 ).

Route wires behind torque tube and tack wires in place with insulated

staples (not supplied).Take care to run wires in a location where they will

not interfere with the operation of the door and do not staple through wire.

Connect photoelectric sensors to the opener terminal block on right side

of the opener. Separate wire ends and strip about 1/2” of insulation off

each of the wire ends. Insert a 3/32” (2.5mm) max. width flathead

screwdriver into the lower hole #1 of the terminal block. Twist screwdriver

to open wire clamp in upper hole #1 of terminal block. Insert both sender

and receiver solid white wires into upper hole #1 until the wires bottom

out and release screwdriver tension. Insert both sender and receiver wires

(white with black stripe) into upper hole #2 by the same process on lower

hole #2 of terminal block. Be sure to observe polarity. Once wires are

connected, install jumper on to the left most set of pins labeled “PE” of

the opener.

IMPORTANT! Keep sender/receiver wires away from moving members.

Pull on external wires to test for secure connection. Check that the wires

are stapled in place and staples have not cut wire insulation. Reconnect

the power to the garage door opener. Proceed to Step 3.

5

Step 2: Photoelectric Safety Sensor Wiring Installation For:

Torsion idrive™ models: 3651-372, 3750-372.

To locate the terminal block for the infrared sensor sender/receiver wires,

you must first move the right hand gear assembly. Loosen the set screw

and slide the gear assembly away from the opener. Uncoil wires from

photoelectric sensors and route wires up garage wall and along door header

towards the right side of the opener (see Fig. 4). Route wires behind

torque tube and tack wires in place with insulated staples (not supplied).

Connect photoelectric sensors to the opener terminal block on right side

of the opener. Separate wire ends and strip about 1/2” of insulation off

each of the wire ends. Insert a 3/32” (2.5mm) max. width flathead

screwdriver into the upper hole #1 of terminal block. Twist screwdriver

to open wire clamp in lower hole #1 of terminal block. Insert both sender

and receiver solid white wires into lower hole #1 until the wires bottom

out and then release screwdriver tension. Insert both sender and receiver

wires (white with black stripe) into lower hole #2 by the same process. Be

sure to observe polarity. Keep the sender and receiver wires straight and

organized by wrapping them around the backside of the opener and securing

them using the cord clip (adhesive backed) provided.(Insure the surface

the cord clip is attached to is clean and oil free.

IMPORTANT! Keep sender/receiver wires away from moving members.

Pull on external wires to test for secure connection. Check that the wires

are stapled in place and staples have not cut wire insulation. Reconnect

the power to the garage door opener. NOTE: Reinstall the right hand

gear assembly onto the drive gear. Ensure that the gear assembly is

installed correctly. Proceed to Step 3

.

White wires

with black

stripe

Solid white

wires

Right hand

gear assembly

Set screw

Insert screw

driver into

lower hole #1

Jumper

installed

Jumper

FIG. 3 Wire Routing

Insert wires

into lower holes

Insert screwdriver

into upper holes

Cord clip

Insert wires

into upper

hole #2

Insert wires

into upper

hole #1

Insert screw

driver into lower

hole #2

Pins

labeled

“PE”

idrive™

FIG. 4 Wire Routing

Torsion idrive™