5

Operating Instructions and Parts Manual Deep Well Submersible Pump

www.waynepumps.com

Installation (Continued)

To prevent sand-

locking pump,

follow this procedure when starting

pump for the first time. Do NOT start

pump with discharge valve completely

open unless you have followed this

procedure first.

1. Connect a pipe elbow, a short length

of pipe, and a gate valve to pump

discharge (at well head).

2. Mount motor control box (for a

3-wire pump) or fused disconnect

switch (for a 2-wire pump) in a

permanently weatherproof place.

Make sure that controls will not be

subjected to extreme heat or excess

moisture.

3. Make sure controls are in OFF

position.

4. Connect motor leads and power

supply to motor control box or

magnetic starter (see Installation

Wiring Diagrams). Do NOT start

pump yet.

5. Open gate valve on discharge one-

third of the way. Start pump (see

Figure 8).

6. Let water run until it is clear. (To

check solids in water, fill a container

with water from pump. If any solids

settle after a minute, continue

running pump.)

7. Once water runs clear, open gate

valve two-thirds of the way and

repeat step 6.

8. Once water runs clear at this setting,

open gate valve completely and run

pump until water is completely clear.

9. Remove gate valve (see Figures 9

and 10).

10. Install sanitary well seal or pitless

adapter unit, well unit, electrical

conduit and surface piping.

Installation must meet all applicable

national and local codes.

CONNECTING TO TANK/WATER

SYSTEM

High pressure and

tank explosion

hazard! To prevent

overpressurization, install a pressure

relief valve capable of releasing pump

air flow at 75 psi (517.1 kPa) when

using air-over-water pressure tank.

When using a pre-charged pressure

tank, install a pressure relief valve that

will release entire air flow at 100 psi

(690 kPa). Install this valve between

pump and tank.

Use only plumber's

seal tape on

threaded joints in plastic pipe. Pipe

joint compound CAN cause cracking in

plastics.

Do NOT allow pump

or piping system to

freeze. Failure to do so COULD result in

serious damage to equipment and WILL

void warranty.

CONTROL

CENTER

OR

ELECTRICAL

DISCONNECT

BOX

TEMPORARY WIRING

TO CONTROL CENTER OR

ELECTRICAL DISCONNECT BOX

TEMPORARY PIPING

GATE VALVE

PUMP IN WELL

Figure 8 - Temporary connections

while cleaning well for startup

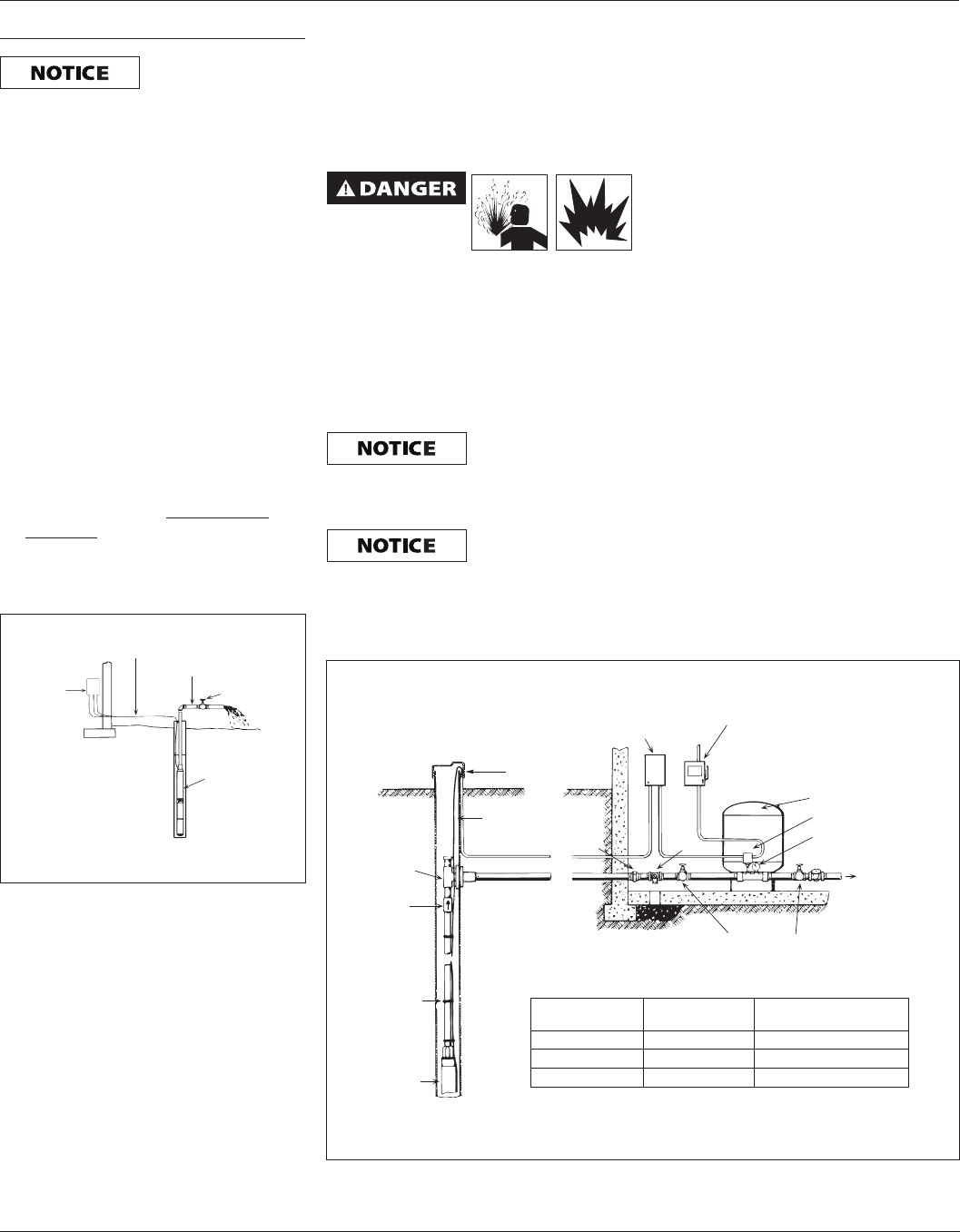

CONNECTING TO TANK/WATER

SYSTEM

See Figure 9 for illustration of piping

connections to pre-charged pressure

tanks.

Before starting pump, check to make

sure that pre-charged air pressure is

2 psi (13.8 kPa) below pump cut-in

setting. (For example, in a tank used

with a 30-50 psi pressure switch, the

pre-charged pressure should be 28 psi

[193.1 kPa].) Adjust pressure by adding

or releasing air from the tire valve

located on top of tank. Check pre-

charged pressure annually and adjust as

needed.

STANDARD TANK HOOKUP

See Figure 10, on page 6, for illustration

of piping connections to standard

pressure tank as well as distance

between air release ports and tank.

VENTILATED

WELL CAP

SUBMERSIBLE

CABLE

PITLESS

ADAPTOR

CHECK

VALVE

TAPE CABLE

TO PIPE

PUMP

CONTROL BOX

(3 WIRE MODELS)

ELECTRICAL DISCONNECT

PRE-CHARGED TANK

PRESSURE SWITCH

PRESSURE GAUGE

TO HOUSE

SERVICE

RELIEF VALVE

UNION

GATE VALVE

CUT IN CUT OFF Pre-charge Tank

PSI (kPa) PSI (kPa) PSI (kPa)

20 (137.9) 40 (275.8) 18 (124.2)

30 (206.8) 50 (344.7) 28 (193.1)

40 (275.8) 60 (413.7) 38 (262)

Figure 9 - Typical Pre-charged Tank Installation