6

NOTE: The BTU input valves on the preceding page show the approximate hourly input of the burner for the various drill

sizes shown. To determine the actual input of the burner:

1) Turn off all other gas appliances.

2) The hand on the dial with the lowest cubic feet value (fastest revolving dial) should be clocked for one complete revolution.

3) Divide 3,600 by the time in seconds for one complete revolution and multiply by the dial value (1 (.028), 2 (.057), or 5

(.142) cubic feet depending on size of meter.)

4) Multiply this by the heating value of the gas to obtain the input to the burner in BTU per hour.

EXAMPLE: Time in seconds for one complete revolution of dial is 72. 3,600 divided by 72 is 50, a 2 cubic foot dial was timed

therefore 50 x 2 is 100. Multiply 100 by heating value of gas which is 1,000 and this will give you an input of

100,000 BTU (29.31 kW) per hour.

IMPORTANT: The minimum gas supply pressure is 4.5” w.c. (1121Pa) for natural gas and 11.0” w.c. (2740Pa) for L.P. gas;

the maximum gas supply pressure is 10.5: w.c. (2615Pa) for natural gas and 13” w.c. (3238Pa) for L.P. gas.

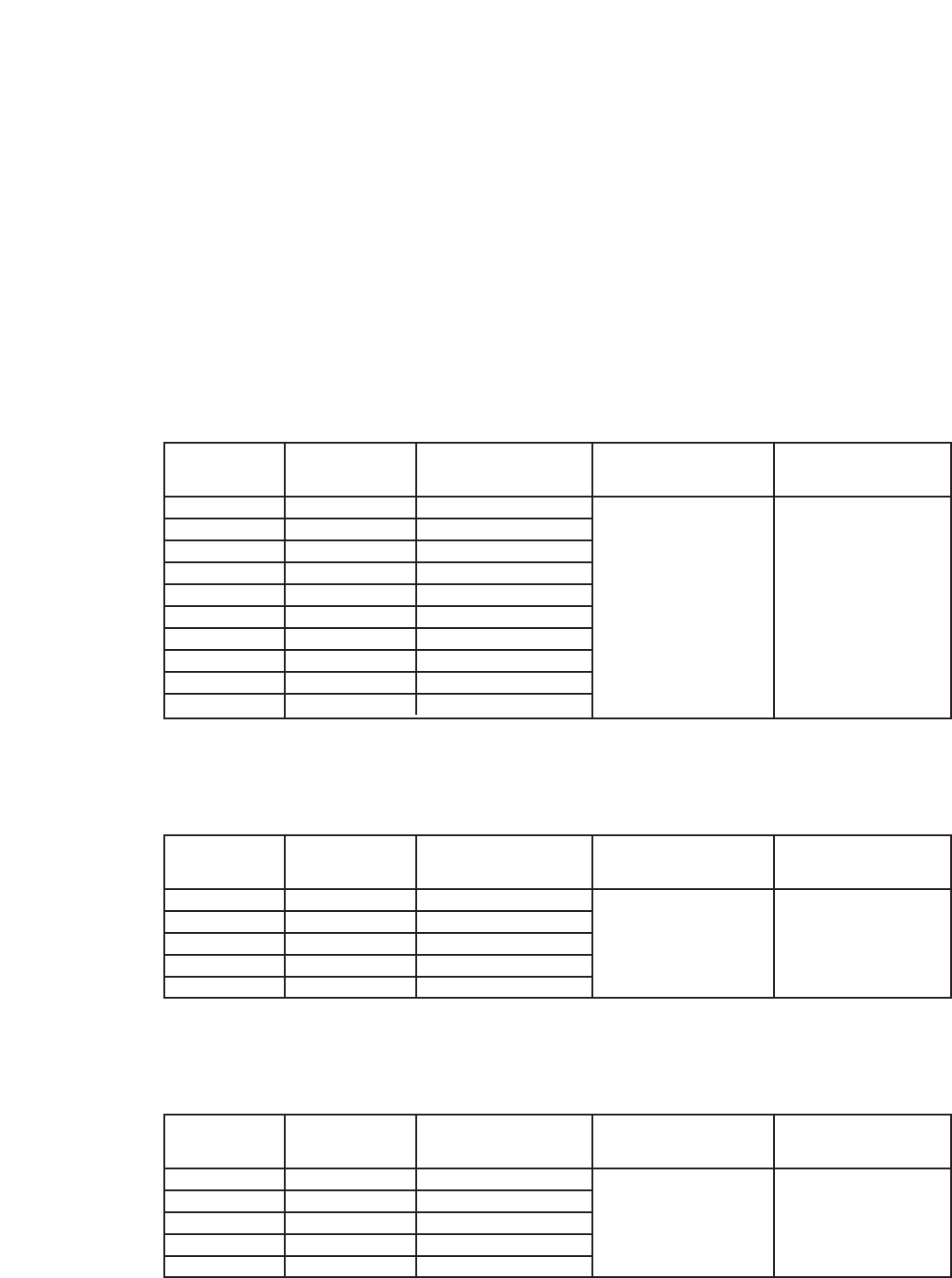

P250 ONLY

Input Floor Area Preferred Recommended Recommended

BTU/Hr. Sq. Inches Width and Minimum Minimum

(kW/Hr.) (mm

2

) Length (mm) Wall Thickness Floor Construction

50,000 (14.65) 49 (31610) 7(177.8)x7 (177.8) 2 1/2” (63.5mm) 2 1/2” (63.5mm)

85,000 (24.91 56 1/4 (36290) 7 1/2(190.5)x7 1/2(190.5) insulating firebrick Insulating firebrick

100,000(29.31) 64 (41290) 8(203.2) X 8(203.2) plus back up of plus 1 1/2” (38.1mm)

120,000(35.17) 72 1/4 (46610) 8 1/2(215.9) x * 1/2(215.9) 1 1/2” (38.1mm) asbestos or magnesia

140,000(41.03 81 (52260) 9(228.6) x 9(228.6) or more loose block.

154,000(45.13) 90 1/4 (58230) 9 1/2(241.3) x 9 1/2(241.3) insulation.

175,000(51.29) 100 (64520) 10(254) X 10(254)

210,000(61.55) 122 (78710) 11(279.4) X 11(279.4)

240,000(70.34) 144 (92900) 12(304.8) x 12(304.8)

250,000(76.2) 156 1/4 (100800) 12 1/2(317.5) X 12 1/2(317.5)

FIGURE 5

P265 ONLY

Input Floor Area Preferred Recommended Recommended

BTU/Hr. Sq. Inches Width and Minimum Minimum

(kW/Hr) (mm

2

) Length (mm) Wall Thickness Floor Construction

65,000 (19.05) 63 (40650) 7 (177.8) x 9 (228.6) 2 1/2” (63.5mm) insulating 2 1/2” (63.5mm) insulating

75,000 (21.98) 71 1/4 (45970) 7 1/2 (190.5) x 9 1/2 (241.3) firebrick plus back up firebrick plus 1 1/2” (38.1mm)

100,000 (29.31) 180 (116100) 7 1/2 (190.5) x 9 1/2 (241.3) of 1 1/2” (38.1mm) or asbestos or magnesia

150,000 (43.96) 200 (129000) 12 (304.8) X 15 (381) more loose insulation. block.

200,000 (58.61) 220 (141900) 13 (330.2) x 17 (431.8)

FIGURE 5A

P265F ONLY

Input Floor Area Preferred Recommended Recommended

BTU/Hr. Sq. Inches Width and Minimum Minimum

(kW/Hr.) (mm

2

) Length (mm) Wall Thickness Floor Construction

65,000 (19.05) 63 (40650) 7 (177.8) x 9 (228.6) 2 1/2” (63.5mm) insulating 2 1/2” (63.5mm) insulating

75,000 (21.98) 63 (40650 7 (177.8) x 9 (228.6) firebrick plus back up firebrick plus 1 1/2” (38.1mm)

100,000 (29.31) 71 1/4 (45970) 7 1/2 (190.5) x 9 1/2 (241.3) of 1 1/2” (38.1mm) or asbestos or magnesia

150,000 (43.96) 110 (70970) 10 (254) x 11 (297.4) more loose insulation. block.

200,000 (58.61) 165 (106500) 11 (297.4) x 15 (381)

FIGURE 5B