4

PREPARATION OF FURNACE OR BOILER

Clean combustion chamber thoroughly. Scrape and brush all heating surfaces and flue ways. Soot and fly ash are excellent

insulators and unless removed the efficiency of the heating plant will be impaired. Plugged or restricted flue passages will

prevent burner from operating properly.

Be sure water column and gauge on boiler is clean and water level is visible. In all cases make sure the pigtail to limit control

is clear. Safety pop valves on team boilers and automatic relief valves on closed water systems should be thoroughly checked

to make sure they are in good working condition.

FLUE PIPE AND DRAFT HOOD

A CSA type draft hood or its equivalent shall be placed in and made part of the flue pipe from the appliance. At no time

should the draft hood be located at a point lower than the highest flue passage in the appliance. The draft hood should be

installed in the position for which it was designed and in no case installed in a false ceiling, separate room from the heating

appliance, or in any other manner that will permit a difference in pressure between the draft hood relief opening and the

combustion air supply. On sealed type appliances where all combustion air is taken from the outside, a cap should be installed

on end of flue pipe to prevent back drafts. In such cases no draft hood or diverter should be installed inside. See Figure 4.

When converting oil fire appliances the flue pipe and draft hood or diverter used should be the same size as the furnace flue

collar. It is recommended that a rise as great as possible or at least 1/4 inch (6.35mm) to the foot (.305m) (horizontal length) be

maintained in the flue pipe from the appliance to the chimney. The flue pipe should be relocated where possible to avoid sharp

turns.

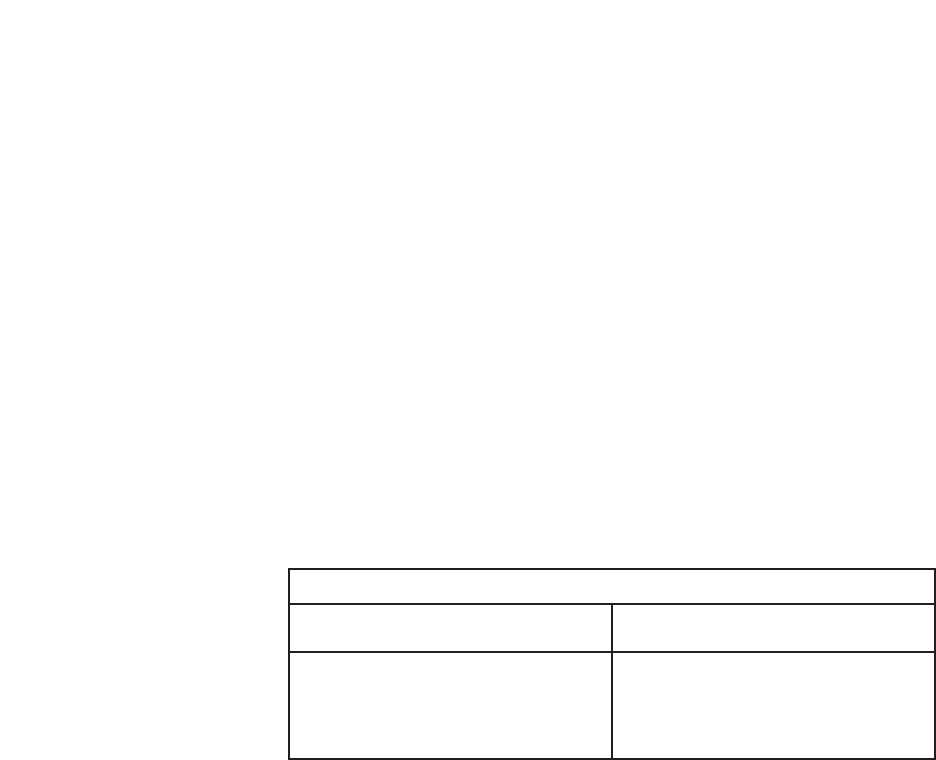

DRAFT HOOD & FLUE PIPE SIZES FOR GAS CONVERSION

BURNERS IN UP-DRAFT COAL FURNACES ND BOILERS

Not more than 6,500 BTU (1.905 kW) per inch (645.2 mm2) of the flue area

Input - BTU (kW) Draft Hood and

Per Hour Flue Pipe Size

Up to --- 120,000 (35.17) 5 inch (127mm)

120,000 (35.17) --- 180,000 (52.75) 6 inch (152.4mm)

180,000 (52.75) --- 250,000 (73.27) 7 inch (177.8mm)

NOTE: If the flue pipe exceeds 10 ft. (3.048m) in length, or contains more than two elbows, use next size larger pipe and

draft hood.

NO MOVEABLE FLUE PIPE DAMPER SHOULD BE USED ON ANY INSTALLATION.

NOTE: All installations must operate with negative draft overfire. Refer to your local gas company and codes for assistance.

REVERTIBLE FLUE (DOWN DRAFT OR DIVING FLUE TYPE) FURNACES OR BOILERS

When installing the burner in the above type furnaces or boilers, the draft hood (or draft diverter) should be located at least

one foot higher than the top of the highest point of the appliance flue passage or combustion chamber. It is also recommended

that a vent pipe, not less than one inch in diameter, be provided from the highest point in the flue passage, directly to the flue

pipe. This is not necessary on the appliances with built in up draft bypass. (See Figure 3.) The gas company serving the area

should be consulted in regards to their recommendations for converting this type of furnace or boiler.

The flue pipe should be securely supported and the joints fastened with sheet metal screws or riveted to prevent sagging,

and in no case should be located in a manner that will present a hazard to combustible building material. (Refer to local building

code.)

PREPARATION OF COMBUSTION CHAMBER

THE POWER GAS BURNER IS DESIGNED FOR “INSHOT” FIRING INTO A REFACTORY LINED COMBUSTION

CHAMBER CONSTRUCTED IN THE ASH PIT OF ANY BOILER OR FURNACE ORIGINALLY DESIGNED FOR COAL OR OIL

FIRING. THE SIZE, SHAPE AND CONSTRUCTION OF THE CHAMBER SHOULD BE GIVEN SUCH CONSIDERATION AS

WILL RESULT IN THE MAXIMUM EFFICIENCY OF EACH INSTALLATION.

On smaller inputs precast chambers may be used if the firing door and ash pit are large enough to insert the chambers and

assemble.

When converting oil designed boilers and furnaces, it is recommended that the same combustion chamber be used with the

gas burner. If the blast tube opening into the combustion chamber is larger than the 4” (101.6mm) diameter, high temperature

cement should be used to reduce the opening to 4” (101.6mm) diameter.

IN NO CASE SHOULD THE TUBE BE ALLOWED TO EXTEND INTO THE CHAMBER PROPER. IT MUST BE AT LEAST

1/8” (3.175mm) SHORT OF THE INSIDE SURFACE OF THE COMBUSTION CHAMBER.