2 ■ User’s Manual Watlow Series 142

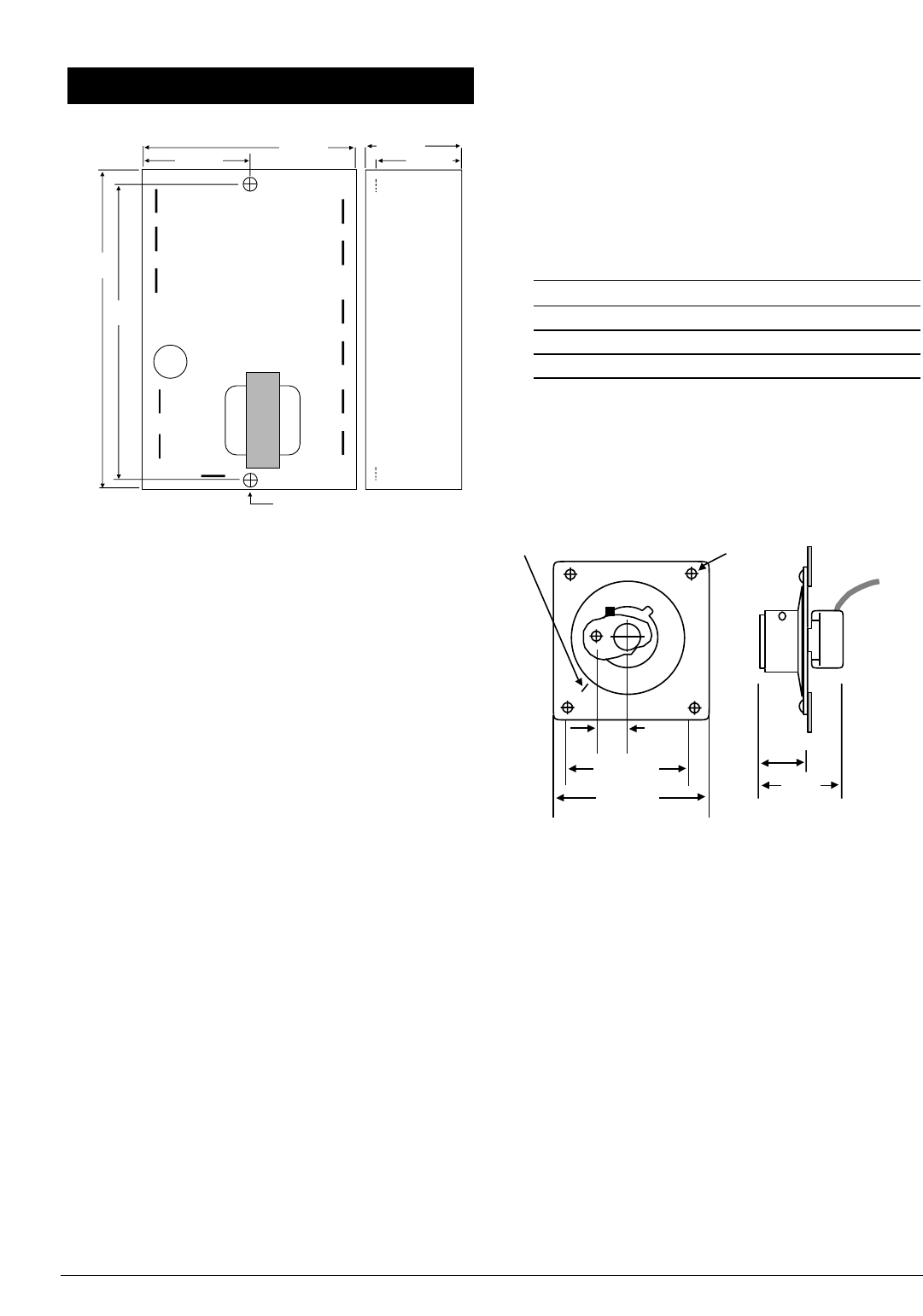

Figure 2a — Series 142 dimensions.

Installation Procedure

1.Drill two 5mm (0.187 in.) diameter holes in the desired

panel location.

2.Mount the unit with two 6-32 screws, 6mm (0.25 in.) hex

nut and #6 internal tooth lock washer.

3.Use the correct thermocouple type per the model num-

ber on the unit sticker. See the side of the case.

• Use correct thermocouple polarity. Red is negative.

• Insulate the thermocouple mounting from the mount-

ing surface to prevent heat migration input errors.

• Thermocouple leads should be twisted pair wire and

routed separately from any other lines.

• In electrically-noisy environments (heavy switching

contactors, motors, solenoids, etc.), use shielded ther-

mocouple lead wire with the shield connected at the

sensor end only.

• Use a separate thermocouple to maintain the limit

function of this controller; do not parallel thermocou-

ple input from the primary

controller.

4.All wiring and fusing must conform to the National

Electric Code (NEC) NFPA70 and any other locally

applicable codes.

5.Fuse the independent load voltage on the L1 (hot) side

and connect it to the common (C) side of the relay.

NOTE: For applications where the CE mark is required, all quick

connect and spade terminals must be pre-insulated to meet IEC

730 specifications.

Units With Remote Setpot Assembly

1.Drill two 51mm (2.0 in.) diameter holes in the desired

remote setpot assembly location. See Figure 2b.

2.Using the dial scale as a location template, center and

mark all four mounting holes on the dial scale with a

center punch.

3.For bolted dial scale assembly, drill four 3mm (0.125 in.)

diameter clearance holes. If you are using a screw

assembly, use a tap drill. Tap drill sizes used are:

Tap Drill Size Screw/Thread Size

#44 - 2mm dia. (0.086 in.) #4.36

#43 - 2mm dia. (0.089 in.) #4.40

#42 - 2mm dia. (0.093 in.) #4.48

4.Drill four 5mm (0.189 in.) diameter holes in desired

panel location. See Figure 2b.

5.Mount the Series 142 with four screws.

6.Connect sensor, load and remote setpot assembly per

Wiring Diagram. See the wiring pages.

Figure 2b — Setpot dimensions and mechanical zero

location.

Dial Scale Alignment to Mechanical Zero

1.Turn the dial scale knob completely counterclockwise (to

mechanical zero).

2.If the “Indicator” line on the setpot knob skirt, and

“Mechanical Zero” (represented by a small line beyond

the low end of the scale) are not aligned, loosen both set

screws on the setpot knob, and rotate the knob until

both lines meet.

3.Tighten both set screws.

13mm

(0.53 in.)

68mm

(2.69 in. sq.)

76mm

(3.00 in. sq.)

4 mounting holes

23mm

(0.9 in.)

Mechanical Zero

43mm.

(1.72 in)

103mm

(

4.05 in.

)

89mm

(

3.50 in.

)

Use a 6mm (0.25 in.) hex nut

for proper clearance.

Two 5mm (0.187 in.) dia.

mounting holes

35mm

(1.38 in.)

70mm

(2.76 in.)

35mm

(

1.38 in.

)

29mm.

(1.13 in)

Installation