VL SERIES STEAMER - ELECTRICAL OPERATION

Pa

g

e 38 of 88

ELECTRICAL OPERATION

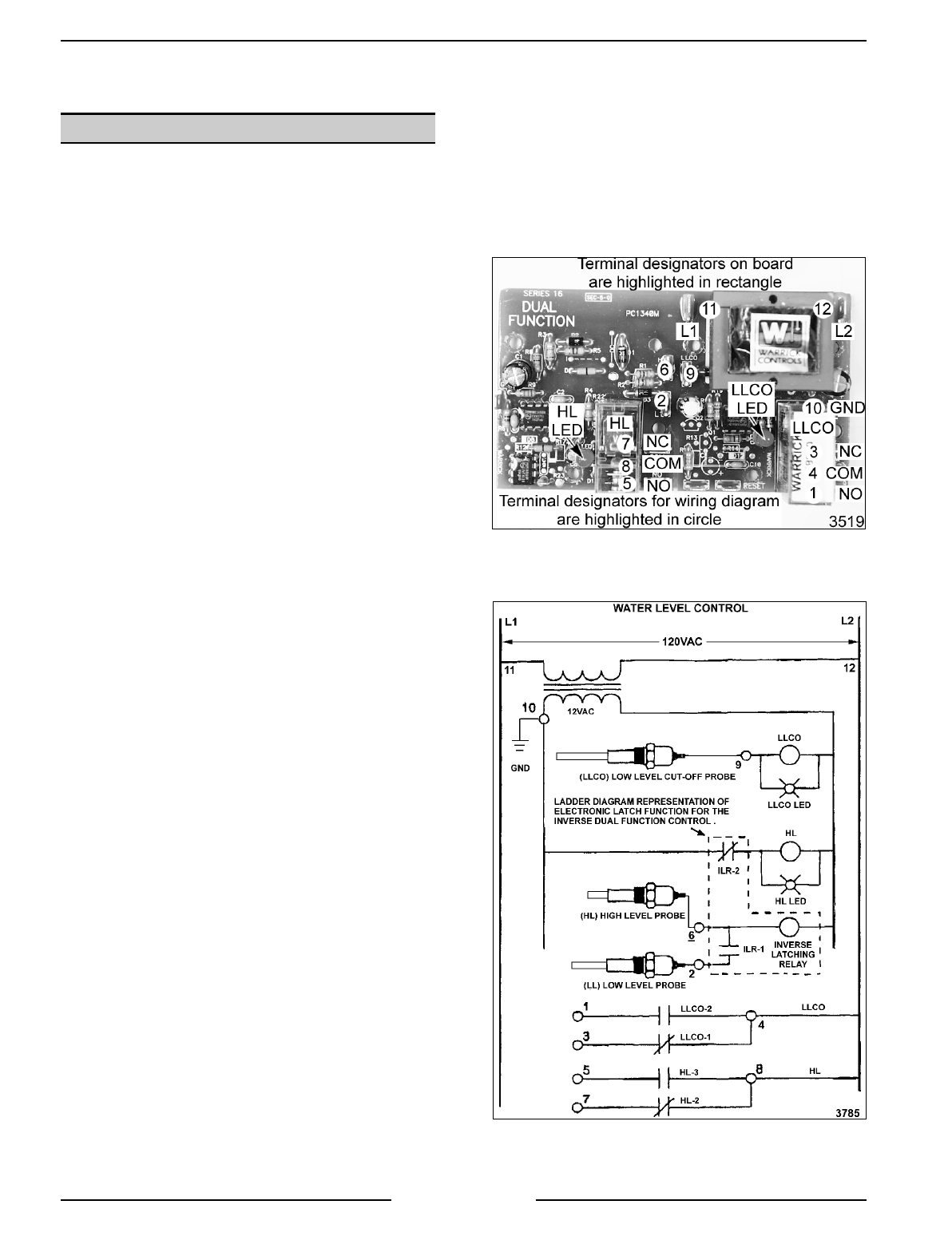

WATER LEVEL CONTROLS

Solid State - Low level Cut-Off & Differential

Control

The steamer is equipped with three water level

sensin

g

probes (hi

g

h, low and low level cut-off) and

a sin

g

le water level control board. The water level

control board performs two functions:

1. Provide low level cut-off protection to shut off

the heat source in case the water level drops

below the low level cut-off (LLCO) probe.

2. Performs as a differential level control to

maintain the water level between the low and

hi

g

h water level probes.

The water level control (WLC) has input volta

g

e

(120VAC) across terminals 11 and 12 which powers

the transformer. On one side of the transformer

secondary, power is provided to the control by a

series path throu

g

h chassis

g

round (terminal 10).

The other side of the transformer secondary

(12VAC) supplies power to one side of the internal

relays LLCO, HL and ILR. As water enters the

boiler, it becomes part of the water level control’s

circuit. When the water level in the boiler reaches a

probe, that circuit is completed.

The inverse latchin

g

relay of the board is de-

ener

g

ized, leavin

g

the ILR-1 (N.O.) and ILR-2 (N.C.)

contacts in their shelf state.

When the main power switch is turned ON, power is

supplied to the WLC board which ener

g

izes the hi

g

h

level (HL) relay and illuminates the HL relay LED.

With the HL-3 contacts closed, the boiler fill

solenoid is ener

g

ized and water be

g

ins fillin

g

the

boiler.

When the water level reaches the low level cut-off

(LLCO) probe, the LLCO relay is ener

g

ized and

illuminates the LLCO LED. With the LLCO-2

contacts closed the heat source is then ener

g

ized.

The LLCO relay will remain ener

g

ized and its LED

will stay lit until the water level in the boiler drops

below the LLCO probe.

When the water level reaches the low level (LL)

probe, power to terminal 2 on the WLC board is

present but no switchin

g

occurs.

After the water level reaches the hi

g

h level (HL)

probe, the inverse latchin

g

relay of the board is

ener

g

ized and locked throu

g

h the low level probe

(LL) and ILR-1 contacts. With ILR-2 contacts open,

this de-ener

g

izes the HL relay and the HL LED

g

oes

out. With the HL-3 contacts open, the boiler fill

solenoid is de-ener

g

ized, stoppin

g

the flow of water

into the boiler.

When the water level drops below the low level (LL)

probe, power is removed from the inverse latchin

g

relay, the HL relay ener

g

izes throu

g

h ILR-2 and HL

contacts chan

g

e state. The fill solenoid is ener

g

ized

throu

g

h HL-3 to refill the boiler and the HL LED is lit.

The HL relay and LED will to

gg

le ON and OFF

durin

g

a cookin

g

cycle as needed.