3

COMBUSTION AIR / VENTILATION

The POWERMAX

tm

must be provided with an adequate supply of air for proper

combustion and ventilation as required by the National Fuel Gas Code, ANSI Z 223.1 or

any local codes that supercede the National Code. Do not obstruct the combustion and/or

ventilation air supply openings.

CAUTION: Combustion air must not be contaminated by corrosive vapors or fumes, i.e.

salt, chlorine, refrigerant gases, detergents, paints, cleaners, etc.. Any damage caused by

insufficient or contaminated combustion air or improper venting will not be covered under

the warranty.

EXHAUST VENTING

The POWERMAX

tm

Booster Heater is classified as a category IV appliance (positive flue

pressure, flue gas temperature of approximately 190 degrees Fahrenheit, possible

condensate). Vent piping must be one of the types detailed in this manual or a factory

approved (in writing) alternate and must be installed according to the vent pipe

manufacturers instructions. All joints must be properly sealed and secured to maintain

joint integrity. All vent piping must slope toward the appliance a minimum of 1/4 inch per

foot of length. The National Fuel Gas Code, ANSI Z223.1 requires that the booster heater

be vented in one of the following three ways:

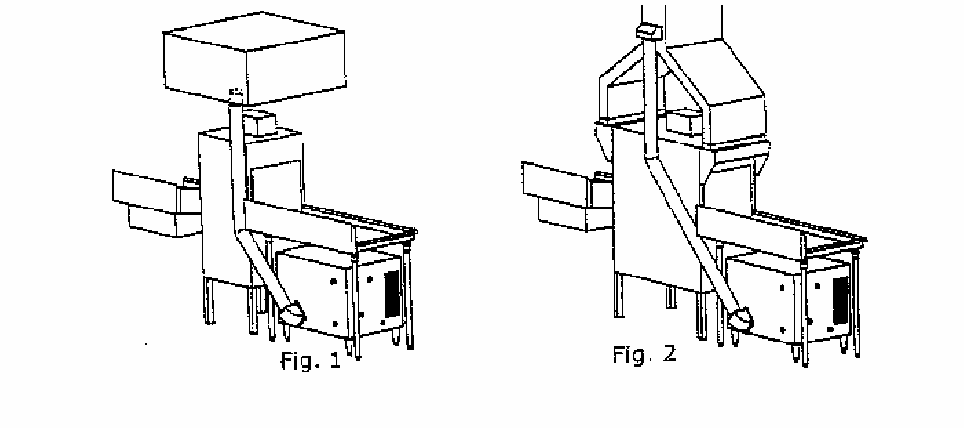

1. Into the dishwasher exhaust system. (See fig.1). The vent pipe must not penetrate

any grease filter, but should terminate within the hood “capture zone”. In cases of a

“pantleg” type of vent (see fig. 2), the vent pipe may terminate below an approved

‘eyebrow’ penetration of the duct. When vented into the dishwasher exhaust system,

an electrical interlock must be provided (by others) to prevent the appliance from

firing if the exhaust system is not providing sufficient draft for any reason.