21

Appendix A

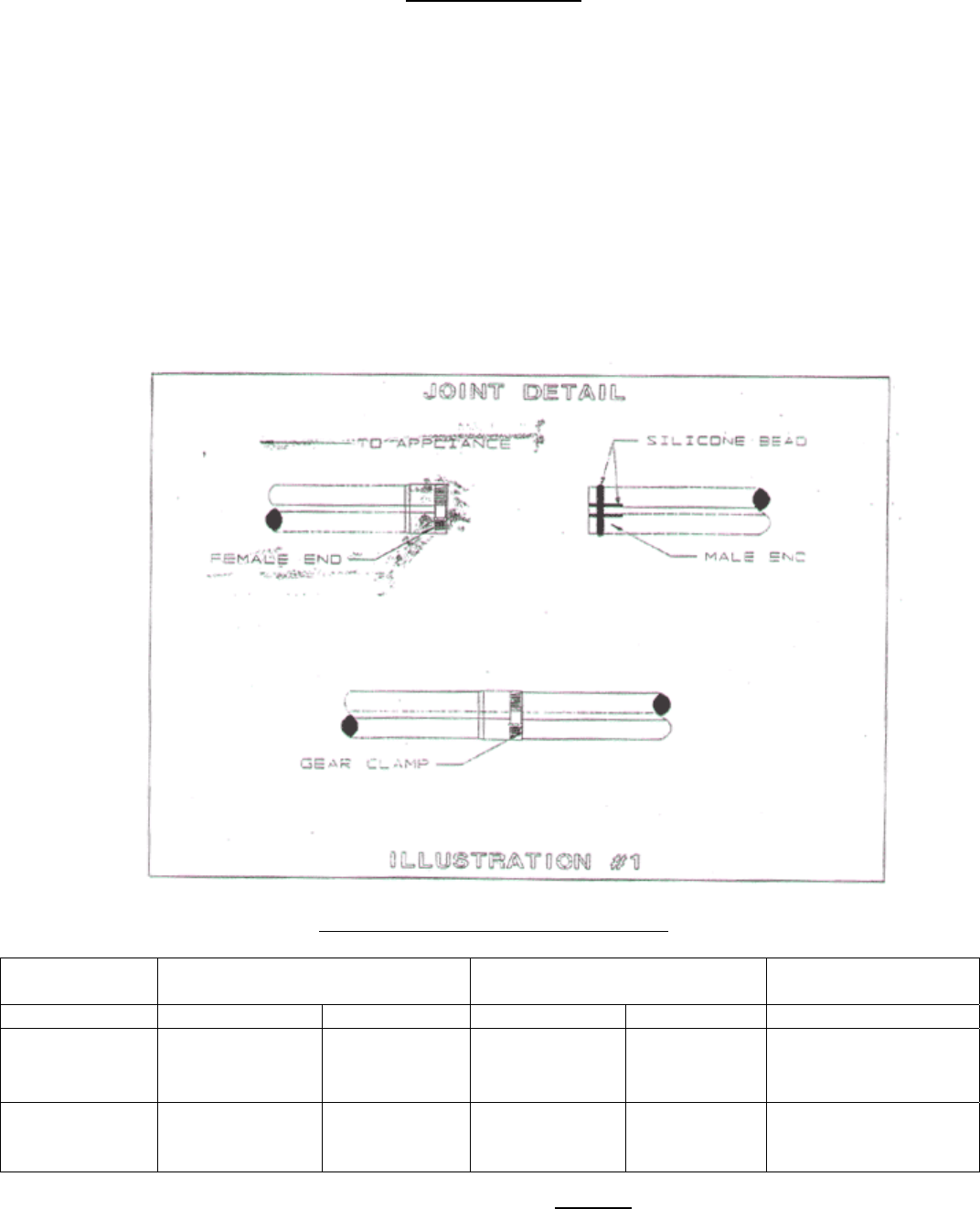

JOINT PROCEDURE

(see illustration #1 below)

1. The outside of male end and inside of female end of pipe must be cleaned before applying silicone

bead. Remove dirt, grease, and moisture from surface to be sealed. Dry surface or allow to dry

thoroughly.

2. Apply high temperature silicone approximately one half inch from end around male end of pipe and

along both sides of seam for one inch in an even 1/4” bead as per illustration #1.

3. Pipes can now be pushed together as far as they will go. The seams on pipes should be aligned and

oriented upwards in all horizontal applications. Apply another bead of silicone around this joint and

smooth out.

4. Tighten gear clamps (15 [N/LB. MAX.).

5. Check all joints and seams for tightness prior to using vent system.

6. Allow the sealant to cure for one hour before operating the appliance. Length of time required for full

cure depends upon thickness of application and other factors such as weather, ambient temperature,

humidity, etc. All sealants must be used within the time limitations marked.

CLEARANCE TO COMBUSTIBLES

SYSTEM

OPERATING

CLEARANCE

ENCLOSED

CLEARANCE

UNENCLOSED

SEALANT

REQUIRED

HORIZONTAL VERTICAL HORIZONTAL VERTICAL

300

O

F (149

O

C) 8” (200 mm) 4” (100 mm) 1” (25 mm) 1” (25 mm)

G.E 108

DOW CORNING 732

Z-FLEX Z-VENT

SEALANT

480

O

F (249

O

C) 8” (200 mm) 4” (100 mm) 1” (25 mm) N/A

G.E 106

Z-FLEX Z-VENT

SEALANT

*Note: Flexible elbows parts # SVEFEX03 AND SVEFEX04 must not be enclosed