18 3

BAROMETRIC DRAFT REGULATOR

Model DR6

SAFETY NOTICE

In the unlikely event that your 2941 "overfires" (a condition evidenced by elbows,

stovepipes, and connectors glowing red in appearance or otherwise discoloring),

then your installation is subject to excessive draft created by either a chimney too tall

or too great in diameter in conjunction with its height, or some other factor of an

indeterminate cause. In this event, you should install a barometric draft regulator.

Such installation will preclude any overfiring and/or any hazardous consequences

of potential overfiring.

Barometric draft regulators are generally available where you purchased your stove

or may be ordered directly from United States Stove Company at a nominal charge.

2001 Consumer Price:

$24.00 - Includes Shipping and Handling

NOTE:

DURING OPENING AND CLOSING OF THE FEED AND ASH DOORS

OF THIS HEATER, IT MAY SEEM THAT THE FIT OF THE DOOR IS

"TOO TIGHT". AS THE HEATER IS FIRED, THE GASKETING

"SETTLES" OR "SEATS" ITSELF IN THE DOOR. THE TIGHT FIT AT

THE FACTORY AND BEFORE THE HEATER'S INITIAL FIRING IS TO

INSURE A GOOD SEAL AFTER THE GASKETING "SETTLES".

NOTE:

FOR YOUR SAFETY, WE RECOMMEND INSTALLING SMOKE

DETECTORS IN YOUR HOME IF NOT ALREADY INSTALLED.

or masonry) must be tall enough to provide

sufficient draft and safe exit of smoke and

combustion products. Please refer to Page

5.

4. Be sure that your Chimney is safely con

structed and in good repair. Have the chim

ney inspected by the Fire Department or a

qualified inspector (such as a Chimney

sweep). Your insurance company may be

able to recommend a qualified inspector.

5. Inspect chimney connector and chimney

twice monthly during the heating season for

any deposit of creosote or soot which must

be removed.

6. Provide air for combustion from outside the

house into the room where the heater is

located. If the intake is not in the same room,

air must have free access to the room.

7. CAST IRON PARTS MUST BE "SEA

SONED" TO AVOID CRACKING. BUILD

ONLY SMALL FIRES ON FIRST USE.

8. To prevent injury, do not allow anyone to

use this heater who is unfamiliar with the

correct operation of the heater. Do not allow

children to use or in any way operate this

heater.

9. For further information on using your heater

safely, obtain a copy of the National Fire

Protection Association (NFPA) publication

"Using Coal and Wood Stoves Safely" NFPA

No. HS-10-1978. The address of the NFPA

is Battery March Park, Quincy, MA. 02269.

10.

Keep the ash pit section free of excess

ashes. Do not allow ashes to stack higher

than the sides of the ash pan.*

11.

DISPOSAL OF ASHES- Ashes should be

placed in a metal container with a tight fitting

lid. Keep the closed container on a non-

combustible floor or on the ground, well

away from all combustible materials. Keep

the ashes in the closed container until all

cinders have thoroughly cooled. The ashes

may be buried in the ground or used as

fertilizer.

12.CAUTION: The special paints used on your

heater may give off some smoke while they

are curing during first few fires. Build small

fires at first. The metal used in construction

of the heater has a light coating of oil. This

could give off smoke and/or odors when

heater is used for the first couple of times.

This should disappear after a short period.

Once this burn-off has occurred, it should

not reoccur.

13.CARING FOR PAINTED PARTS- This

heater has a painted outside jacket, which is

durable but will not stand rough handling or

abuse. When installing your heater, use

care in handling. Clean with soap and warm

water when heater is not hot. DO NOT use

any harsh chemicals (acids or caustics) or

scouring powder, as these wear and dull the

finish.

14.KEEP THE FEED DOOR, ASH DOOR AND

CABINET DOOR CLOSED AT ALL TIMES

EXCEPT WHILE TENDING THE HEATER.

DO NOT OVERFIRE THE HEATER. THIS

WILL HAPPEN IF THE FEED DOOR, OR

PARTICULARLY THE ASH DOOR, IS LEFT

OPEN DURING OPERATION. UNDER EX

TREME CONDITIONS THIS CAN PRO

DUCE DANGEROUS RESULTS. AT A

MINIMUM, IT WILL ALLOW THE PAINT TO

DISCOLOR.

* Never allow ashes to contact the grate(s).

CAUTION: DO NOT TOUCH THE

HEATER UNTIL IT HAS COOLED.

ALWAYS WEAR GLOVES WHEN

REFUELING THIS UNIT OR WORKING

WITH METAL CABINET PARTS.

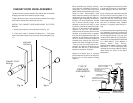

MINIMUM CLEARANCES TO COMBUSTIBLE WALLS AND CEILINGS

Minimum clearances to unprotected combustible walls and ceilings as noted by figures 2 through

4 must be maintained. Drapes, curtains, furniture and other combustible materials should be kept

much further away from the heater to avoid fire. If you choose to, you may install the heater and

chimney connector closer to combustible surfaces than indicated by Figures 2 through 4 IF a

clearance reduction system is also installed to protect combustible ceilings and walls near the

heater and chimney connector. However, there are limits to how close the heater and chimney

connector can be installed to combustible surfaces protected by a clearance reduction system.

A correctly installed clearance reduction system protects the combustible surfaces well beyond

the sides and above the top of the heater and beyond the sides and top of the chimney connector

pipe.

Two common types of clearance reduction systems use sheet metal with a minimum thickness

of 28 gauge (galvanized steel, aluminum, copper) or a 3-1/2 inch (4 inch nominal) thick masonry

wall. Either of these materials must be spaced out 1 inch from the combustible surfaces. With

sheet metal, non-combustible spacers are used to maintain the 1 inch air space. With a masonry

wall, metal wall ties and furring strips, if needed are used to anchor the brick to the wall. To avoid

excessive heat transmission, the spacers or wall ties should not be placed directly behind the