unigreen 9

4.2 PRELIMINARY CHECKS

When you receive the machine, check that it is complete and no parts are

missing.

If there are any damaged parts, inform your local reseller or UNIGREEN

directly in good time.

When the machine is delivered, make sure you ask:

a) that the machine is delivered with all of its parts fitted and that the fitting

meets the requisites in table N° 14b-15b-16b (pages 37, 38, 39).

This procedure is necessary because for reasons of space during

transportation the machine is often delivered partially dismantled.

b) that it is tested in your presence in particular checking:

= that the suction filter and the inside of the tank are clean and free of work

residues.

= that the connections are made correctly following the basic layout (FIG. N°

17, page 16).

= that the hose clips and all the unions and connections are tightened

properly.

= that all of the protective covers are fitted solidly to the machine, in

particular the protective cover of the power-takeoff of the pump.

= that the multiplier is sufficiently supplied with lubricant oil.

= that the zone where the fan turns hasn’t been bent by knocks during

transportation.

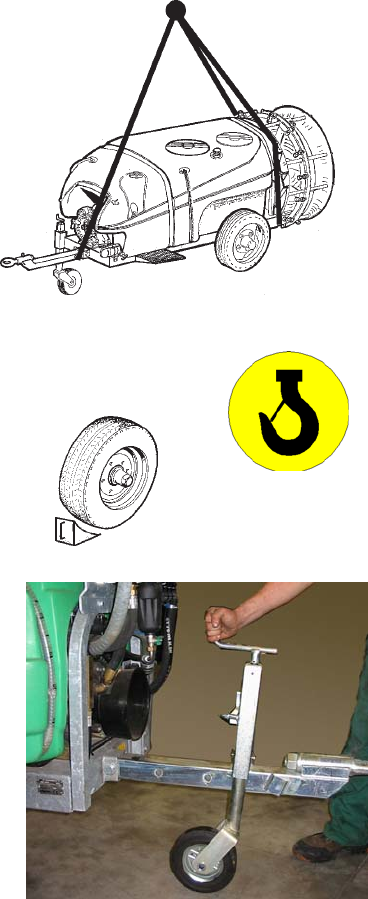

4.3 TRANSPORTING AND MOVING THE MACHINE

Every time you have to lift the machine, before starting the operation, always

make sure the lifting gear and the relevant tools and equipment (cables, hooks,

etc..) are suitable for lifting the load and check the stability of the same.

It is forbidden to unhook and move the machine with the tank full.

The dry weight of the machine at the maximum level of fitting and with all the

accessories allowed is stamped on the nameplate; use slings and lifting gear

with a adequate load-bearing capacity (FIG.3).

Never lift or move the mistblowers by hand if there is liquid in the tank. The

machine will weigh more and the movement of the liquid can change the centre

of gravity causing uncontrolled movements.

We recommend using slings as shown in the figure, the lifting points to use on

the machine are indicated with the relevant symbol.

Don’t lift the machine with the forks of a forklift truck because the machine can

tip over due to the overhanging weight of the blower group.

Don’t pass or stand under the machine when it is being lifted.

4.3.1 TOWED ATOMISERS

PARKING

Don’t stand the mistblower on unstable ground or steep slopes, the machine is

designed to be parked safely on compact ground with a slope of up to 8.5°

using the relevant chocks (FIG. 4) in the following way:

- Machine parked with drawbar uphill (max 8.5°), place the chocks behind

the wheels.

- Machine parked with drawbar downhill (max 8.5°), place the chocks in front of

the wheels.

- Machine parked across the slope (max 8.5°), place one chock in front of the

drawbar wheel (in the direction of the slope) and the other in front of the wheel

uphill.

MOVING

To lift the machine, follow the instructions above.

The towed mistblowers have an extendable drawbar parking wheel so the

machine can be moved around by hand on flat, compact ground, with the tank

empty.

To make moving the mistblower around easier when it is disconnected from the

tractor, on the machine and on the drawbar there are supports for positioning the:

- cardan shaft: hinged rest on the drawbar parking wheel.

- manual pressure regulator: bayonet housing on the drawbar.

- electric pressure regulator: pushbutton panel support (the cable must be

coiled around the same to stop it getting in the way).

- Brake levers if fitted: bayonet housing on the drawbar.

This symbol

identifies the

coupling points

of the machine

FIG.3

FIG.4

Only move and lift the machine

with the tank empty