NOTE: DIAGRAMS & ILLUSTRATIONS ARE NOT TO SCALE.

10

DETAILED INSTALLATION STEPS

TYPICAL INSTALLATION SEQUENCE

The typical sequence of installation follows,

however, each installation is unique resulting

in variations to those described.

See the Page numbers references in the follow-

ing steps for detailed procedures.

Step 1. (Page 10) Construct the appliance fram-

ing. Position the appliance within the framing and

secure with nailing fl anges.

Step 2. (Page 10) Route gas supply line to appli-

ance location.

Step 3. (Page 13) Install the vent system and

exterior termination.

Step 4.(Page 25) Field Wiring

a. Millivolt Appliances – Install the OFF/ON

burner control switch.

b. Electronic Appliances – Connect 120 VAC

electrical power to the appliance receptacle.

Step 5. (Page 26) Install blower kit (optional

equipment).

Step 6. ( Page 27) Make connection to gas

supply.

Step 7. (Page 28) Checkout appliance operation.

Step 8. (Page 28) Install embers, volcanic stone

and embers.

Step 9. (Page 29) Install glass enclosure pan-

els.

Step 10.(Page 29) Adjust burner primary air shutter

to achieve proper fl ame appearance.

Step 11 (Page 30) Install the decorative trim and

hoods.

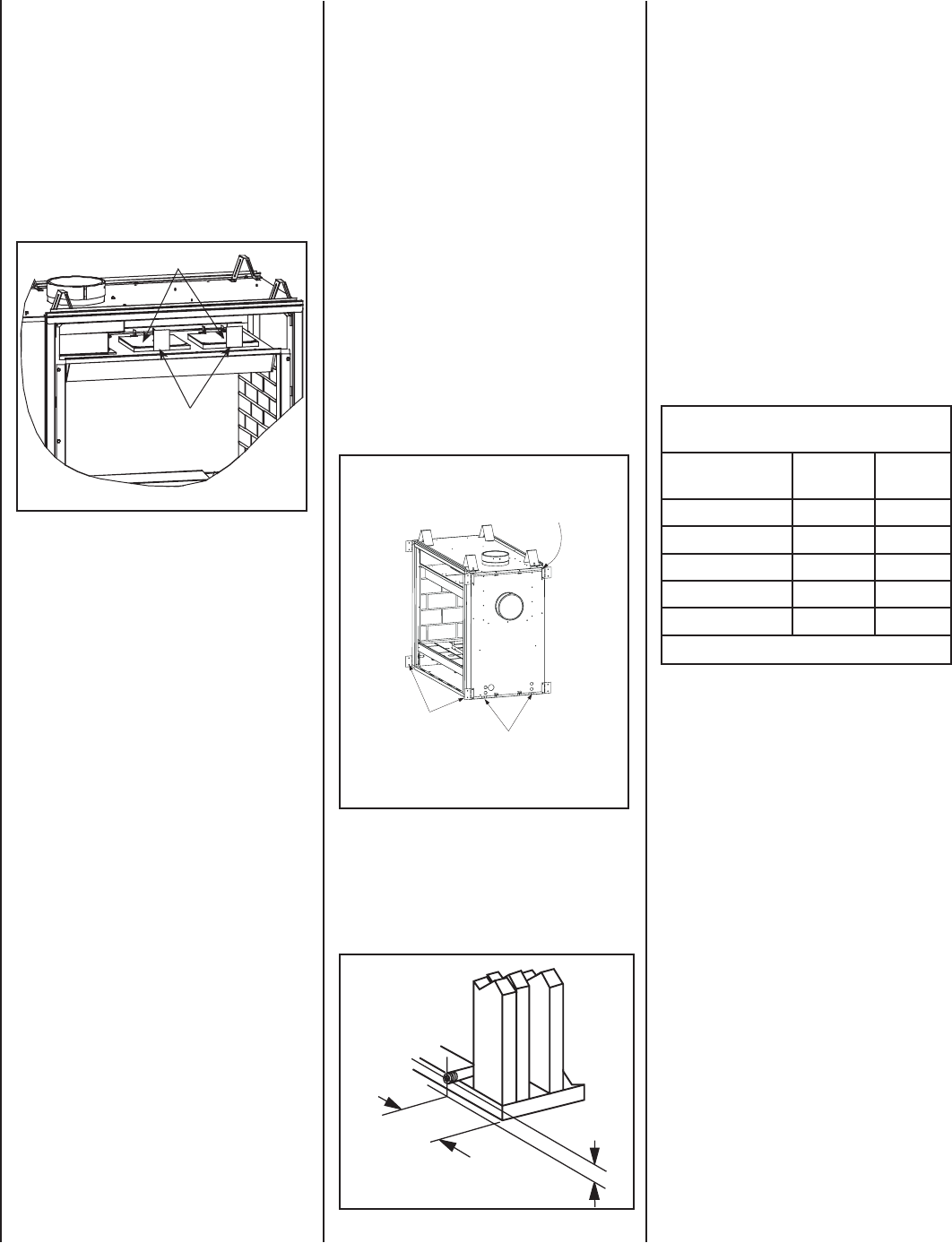

Step 1. FRAMING

Frame these appliances as illustrated in Figures

13 & 14. All framing details must allow for a

minimum clearance to combustible framing

members as shown in Table 7 on Page 9.

1. Remove the shipping carton.

2. Remove the top louvered panel and locate the

pressure relief plates.

3. Lift the pressure relief plates and remove

the cardboard from beneath each plate (be

careful not to damage the white gasket). See

Figure 10.

* NOTE: INSTALLATION DIAGRAMS AND

INSTRUCTIONS SHOW THE FRONT OF

THE APPLIANCE AS THE SIDE WHICH HAS

VALVE ACCESS, EXCEPT WHERE NOTED.

Also see

Figures 13 & 14

5-5/8"

(143 mm)

3-1/8"

(79 mm)

Figure 12 - ROUTE GAS LINE

Proper Sizing of Gas Line

Properly size and route the gas supply line

from the supply regulator to the area where the

appliance is to be installed per requirements

outlined in the National Fuel Gas Code, NFPA

54 - latest edition (USA) or B149 - latest edition

(Canada). Never use galvanized or plastic pipe.

Refer to Table 8 for proper sizing of the gas

supply line, if black iron pipe is being used. Gas

lines must be routed, constructed and made

of materials that are in strict accordance with

local codes and regulations. We recommend

that a qualifi ed individual such as a plumber

or gas fi tter be hired to correctly size and route

the gas supply line to the appliance. Installing

a gas supply line from the fuel supply to the

appliance involves numerous considerations of

materials, protection, sizing, locations, controls,

pressure, sediment, and more. Certainly no one

unfamiliar and unqualifi ed should attempt sizing

or installing gas piping.

Schedule 40 / Black Iron Pipe

Inside Diameter (Inches)

Schedule 40 Pipe

Length (feet)

Natural

Gas

Propane

Gas

0-10 1/2 3/8

10-40 1/2 1/2

40-100 1/2 1/2

100-150 3/4 1/2

150-200 3/4 1/2

Table 8

Notes:

• All appliances are factory-equipped with a

fl exible gas line connector and 1/2 inch shutoff

valve (see Figure 47 on Page 27).

• See Massachusetts Requirements on Page

3 for additional requirements for installations

in the state of Massachusetts in the USA.

• The gas supply line should Not be connected

to the appliance until Step 6 (Page 27).

• A pipe joint compound rated for gas should be

used on the threaded joints. Ensure propane

resistant compounds are used in propane

applications. Be very careful that the pipe

compound does not get inside the pipe.

• It is recommended to install a sediment trap

in the supply line as close as possible to the

appliance (see Figure 47). Appliances using

Propane should have a sediment trap at the

base of the tank.

• Check with local building offi cial for local code

requirements (i.e. are below grade penetrations

of the gas line allowed?, etc).

IMPORTANT: If propane is used, be aware that

if tank size is too small (i.e. under 100-lbs, if

this is the only gas appliance in the dwelling.

Ref. NPFA 58), there may be loss of pressure,

resulting in insuffi cient fuel delivery (which

can result in sooting, severe delayed ignition

or other malfunctions). Any damage resulting

from an improper installation, such as this, is

not covered under the limited warranty.

Step 2. ROUTING GAS LINE

Route a gas line along the inside of the right side

framing as shown in Figure 12. Gas lines must

be routed, constructed and made of materials

that are in strict accordance with local codes

and regulations.

If the appliance is to be elevated above fl oor

level, a solid continuous platform must be

constructed. Headers may be in direct contact

with the appliance top spacers but must not be

supported by them or notched to fi t around them.

All construction above the appliance must be

self supporting, DO NOT USE THE APPLIANCE

FOR STRUCTURAL SUPPORT.

Side Nailing Flanges

The fi replace should be secured to the fram-

ing at the side(s) of the appliance using the

factory-provided nailing fl anges. Install the 8

nailing fl anges as shown in Figure 11 using the

existing screws. Position the fi replace within

the framing. When required, the tabs may be

bent 90 degrees by hand or with the assistance

of a hammer. Use wood screws to secure the

nailing fl anges to the framing. See Table 7 on

Page 9 for clearances of framing members

to cabinet parts. The nailing fl ange itself can

directly contact framing.

Floor Nailing Tabs - Secure the fi replace to the

fl oor as shown in Figure 11.

Figure 11 - Nailing Flanges

Remove these screws and use them

when installing nailing fl anges.

Nailing Flanges

Turn nailing tabs down and secure to fl oor with 8d

nails or other appropriate fasteners on both sides of

appliance which do not have viewing glass panels.

SSDVST Shown (SSDVPF - No nailing

fl anges on end with glass panel)

Figure 10

REMOVE

C

A

R

D

B

O

A

R

D

BEF

O

R

E U

S

IN

G

REMOVE

C

A

R

D

B

O

A

R

D

BEF

OR

E

US

IN

G

Pressure Relief Plates

Remove Cardboard Before

Using Appliance