Page 15

SEQUENCE OF OPERATION

GENERAL

Operation of the unit heating and cooling cycles is automatic for

HEAT and COOL functions. (The optional automatic changeover

thermostat, when in the AUTO position, automatically changes to

heat or cool with sufficient room temperature change.) The fan

switch can be placed in either the ON position, causing continuous

evaporator (indoor) fan operation, or the AUTO position causing fan

operation to coincide with heating or cooling run cycles.

COOLING MODE

(NOTE: TSH & TSC are contacts internal to the indoor thermostat.)

With the disconnect switch in the ON position, current is supplied to

the compressor crankcase heater and control transformer. (The

outdoor fan relay (ODF) relay is energized through normally closed

contacts on the defrost timer control (DFC) on the 460V and 600V

units only.) The cooling cycle is enabled through the low voltage

side of the control transformer to the “R” terminal on the indoor

thermostat. With the system switch in the AUTO position and TSC-

1 contacts closed, power is supplied to the “O” terminal on the

indoor thermostat to the switchover valve coil (SOV). This energizes

the switch-over valve (SOV) and places it in the cooling position (it

is in the heating position when de-energized).

When the indoor temperature rises 1-1/2 degrees, TSC-2 contacts

close, supplying power to the “Y” terminal on the indoor thermostat,

and to the compressor contactor (CC). This starts the outdoor fan

motor and compressor. The TSC-2 contacts also provide power to

the “G” terminal which provides power to the fan relay (F) starting

the indoor fan motor.

HEATING MODE

With the disconnect switch in the “ON” position, current is supplied

to the compressor crankcase heater and control transformer. (The

outdoor fan relay (ODF) is energized through normally closed

contacts on the defrost timer control (DFC) on the 460V and 600V

units.) Starting at the “R” terminal on the indoor thermostat, current

goes through the system switch (which is in “AUTO” position) to the

TSH-1 contacts. When closed, these contacts supply power to

terminal ”Y” on the indoor thermostat as well as to the heating

anticipator. The switch-over valve will not energize because of the

high resistance of the heating anticipator in the thermostat. Power

is provided from “Y” to the compressor contactor (CC) which starts

the compressor and outdoor fan motor. The indoor thermostat

contact TSH-1 also provides power to “G” terminal on the indoor

thermostat energizing the fan relay (F), which starts the indoor fan

motor.

SUPPLEMENTARY HEAT

The supplementary electric heat is brought on when the indoor

temperature drops 1-1/2 degrees below the thermostat setting.

TSH-2 contacts close providing power to the “W” terminal on the

indoor thermostat and to the supplementary heater control circuit.

NOTE: The fan relay (F) must have been energized. An outdoor

thermostat may have been added to disallow the second stage (if

provided) of electric heat above a selected outdoor temperature. If

the outdoor temperature falls below the setting on the outdoor

thermostat, this additional heater stage will come on. When the

outdoor air temperature rises, and the outdoor T-stat setpoint is

reached, the system will revert back to first stage electric heating.

When the indoor ambient is satisfied, TSH-2 contacts will open and

the unit will revert back to the compressor only heating mode and

then off. For emergency heat (use of supplementary electric heat

only), an emergency (EMERG) heat switch is provided within the

thermostat. When placed in the emergency heat position, it will

disable the compressor, bypass the outdoor thermostats, if pro-

vided, and engage the supplementary electric heaters and indoor

fan.

DEMAND DEFROST OPERATION

During the heating cycle, the outdoor coil may require a defrost

cycle which is determined by the demand defrost control (DFC).

This control continuously measures the outdoor coil temperature

(CBS) and the outdoor ambient temperature (ODS-B) and calcu-

lates the difference or delta-T measurement. When the calculated

delta-T is met, the demand defrost control (DFC) opens the circuit

to the outdoor fan motor (ODM) and energizes the switch-over valve

(SOV), placing the unit in the cooling mode to defrost the outdoor

coil. The outdoor coil temperature sensor (CBS) terminates the

defrost cycle, or times off after twelve minutes in defrost, the (DFC)

energizes the outdoor fan motor (ODM) and twelve seconds later

de-energizes the (SOV), which returns the unit to the heating mode.

Supplementary electric heat, if provided, is brought on to control

indoor temperature during the defrost cycle.

ICM FAN MOTOR ADJUSTMENTS

If the airflow needs to be increased or decreased, see the Airflow

Table in the Service Facts. Information on changing the speed of the

blower motor is in the Blower Performance Table.

Blower speed changes are made on the ICM Fan Control mounted

in the control box. The ICM Fan Control controls the variable speed

motor.

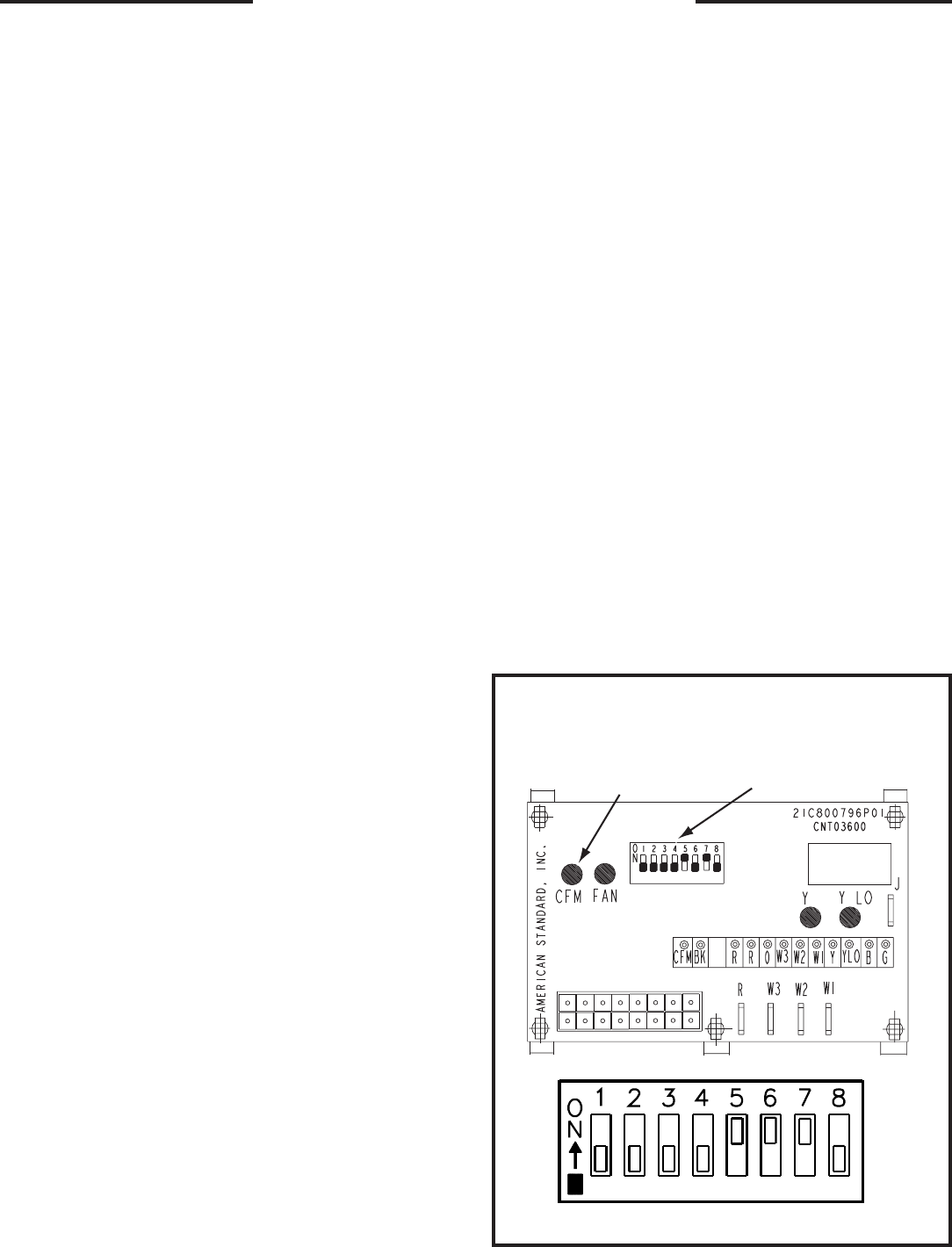

There is a bank of 8 dip switches, (See Figure 15), located at the

upper right side of the board. The dip switches work in pairs to match

the cooling/heat pump airflow (CFM/TON), Fan off-delay options,

and electric heat airflow adjustment. The switches appear as shown

in Figure 15.

t

DIP SWITCHES (TYPICAL SETTINGS)

ICM FAN CONTROL

CFM

SELECTION

LIGHT

DIP

SWITCHES