48

PURGE

Supply Fan - On

Inlet Vanes - Open (if equipped)

Exhaust Fan - On (if equipped)

Exhaust Dampers - Open (if equipped)

OA Dampers - Open

Heat - All heat stages Off (staged gas and elec.), Hydronic

heat & Mod Gas Heat output at 0%.

Occupied/Unoccupied output - Energized

VO Relay - Energized (with VOM module installed)

OA Preheater State - Off (with VCM module installed)

SHUTDOWN

Supply Fan - Off

Inlet Vanes - Closed (if equipped)

Exhaust Fan - Off (if equipped)

Exhaust Dampers - Closed (if equipped)

OA Dampers - Closed

Heat - All heat stages Off (staged gas and elec.), Hydronic

heat & Mod Gas Heat output at 0%.

Occupied/Unoccupied output - De-energized

VO Relay - Energized (with VOM module installed)

OA Preheater State - Off (with VCM module installed)

FIRE

Supply Fan - Off

Inlet Vanes - Closed (if equipped)

Exhaust Fan - Off (if equipped)

Exhaust Dampers - Closed (if equipped)

OA Dampers - Closed

Heat - All heat stages Off (staged gas and elec.), Hydronic

heat & Mod Gas Heat output at 0%.

Occupied/Unoccupied output - De-energized

VO Relay - Energized (with VOM module installed)

OA Preheater State - Off (with VCM module installed)

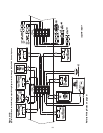

Emergency Stop Switch (5S71)

A normally closed (N.C.) switch (5S71) wired to the RTM

may be used during emergency situations to shut down all

unit operations. When opened, an immediate shutdown oc-

curs. An emergency stop diagnostic is entered into the Hu-

man Interface and the unit must be manually reset. Refer to

the appropriate illustrations in Figure 3-16 or 3-17 for the

proper connection terminals in the unit control panel. The

switch must be rated for 12 ma @ 24 VDC minimum.

Occupied/Unoccupied Contacts (5K86)

To provide Night Setback control if a remote panel with NSB

(5U58) was not ordered, a field supplied contact (5K86)

must be installed. This binary input provides the Occupied/

Unoccupied status information of the building to the RTM. It

can be initiated by a time clock, or a Building Automation

System control output. The relay’s contacts must be rated

for 12 ma @ 24 VDC minimum. Refer to the appropriate il-

lustrations in Figure 3-16 or 3-17 for the proper connection

terminals in the unit control panel.

Demand Limit Relay (5K89)

If the unit is equipped with a Generic BAS Module (1U51),

(i.e. unit model number digit 21+ is a “K”), a normally open

(N.O.) switch may be used to limit the electrical power us-

age during peak periods. When demand limit is initiated, the

mechanical cooling and heating operation is limited to either

50% or 100%. Demand limit can be initiated by a toggle

switch closure, a time clock, or an ICS

TM

control output.

These contacts must be rated for 12 ma @ 24 VDC mini-

mum.

Outside Air Sensor (3RT3) - BAYSENS016A

This device senses the outdoor air temperature and sends

this information in the form of an analog input to the RTM.

It's factory installed on units with an economizer, but can be

field provided/installed and used for informational purposes

on units without an economizer. Refer to the appropriate il-

lustrations in Figure 3-16 or 3-17 for the proper connection

terminals in the unit control panel. Refer to Table 3-10 for

Temperature vs Resistance coefficient.

Generic Building Automation System (1U51)

The Generic Building Automation System (GBAS) module

allows a non-Trane building control system to communicate

with the rooftop unit and accepts external setpoints in form

of analog inputs for cooling, heating, demand limiting, and

supply air pressure parameters. Refer to Figure 3-18 for the

input wiring to the GBAS module and the various desired

setpoints with the corresponding DC voltage inputs for both

VAV and CV applications.

For complete application details of the module, refer to

Engineering Bulletin UN-PRB001-EN.

Resistance Resistance

Temperature (F) (in. 1000 Ohms) Temperature (F) (in. 1000 Ohms)

-40 346.1 71 11.6

-30 241.7 72 11.31

-20 170.1 73 11.03

-10 121.4 74 10.76

-5 103 75 10.5

0 87.56 76 10.25

5 74.65 77 10

10 63.8 78 9.76

15 54.66 79 9.53

20 46.94 80 9.3

25 40.4 85 8.25

30 34.85 90 7.33

35 30.18 100 5.82

40 26.22 105 5.21

45 22.85 110 4.66

50 19.96 120 3.76

55 17.47 130 3.05

60 15.33 140 2.5

65 13.49 150 2.05

66 13.15 160 1.69

67 12.82 170 1.4

68 12.5 180 1.17

69 12.19 190 0.985

70 11.89 200 0.83

Table 3-10 - Temperature vs. Resistance Coefficient

The UCM network relies on various sensors located

throughout the system to provide temperature information in

the form of an analog input. All of the sensors used have

the same temperature vs. resistance co-efficient and are

made from Keystone Carbon D97 material with a 1 degree

Centigrade tolerance.