SS-SVX09A-EN 93

System Start-Up

14. Turn the 115-volt control circuit switch 1S2 to the “OFF” position and open the field provided

or optional factory mounted disconnect switch.

15. After shutting the system off, check the compressor oil appearance. Discoloration of the oil

indicates that an abnormal condition has occurred. If the oil is dark and smells burnt, it has

overheated because of: compressor is operating at extremely high condensing temperatures;

high superheat; a compressor mechanical failure; or, occurrence of a motor burnout.

If the oil is black and contains metal flakes, a mechanical failure has occurred. This symptom

is often accompanied by a high compressor amperage draw.

If a motor burnout is suspected, use an acid test kit to check the condition of the oil. Test results

will indicate an acid level exceeding 0.05 mg KOH/g if a burnout occurred.

Compressor Oil

The scroll compressor uses Trane OIL-42 without substitution. The appropriate oil charge for

a 9 and 10 Ton scroll compressor is 8.5 pints. For a 14 and 15 Ton scroll compressor, use 13.8 pints.

Compressor Crankcase Heaters

9 and 10 ton scroll compressors have a 100-watt heater installed. 14 and 15 ton scroll compressors

have two 80-watt heaters installed per compressor.

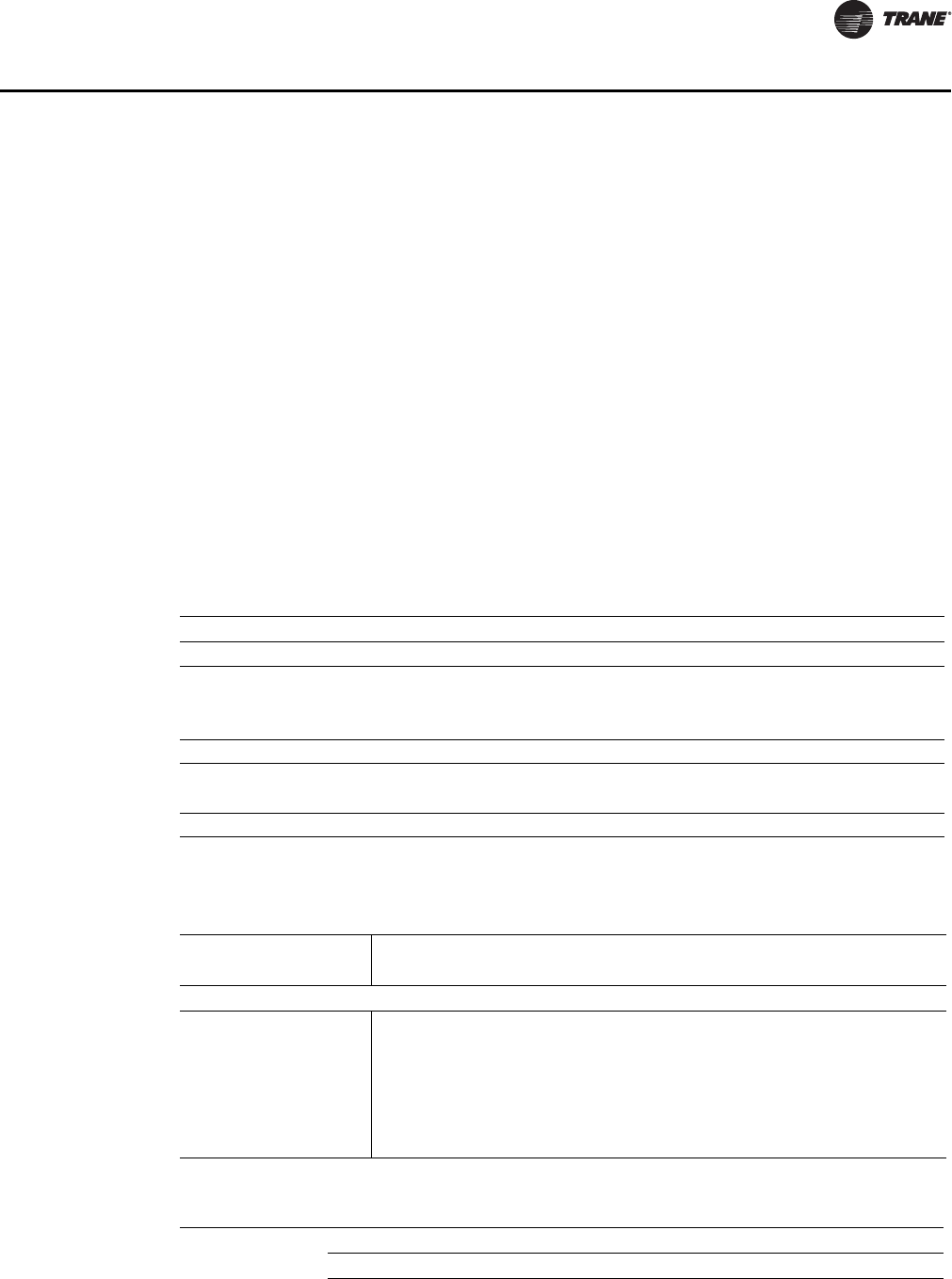

Table 13. Pressure Control Switch Settings

Pressure Switch Make Break

Hi Pressure 350 psi 405 psi

Lo Pressure

EVPB

All others

60 psi 45 psi

40 psi 30 psi

Condenser Fan Cycling switch 275 psi 155 psi

(EVP only w/HGB - wo/HGB) std.

Lo Ambient Thermostat 33 F 30 F

Compressor Winding T-Stat 181F 221 F

Note: Pack Stock units will have both low pressure switches shipped and the user should use the above valves that apply

Table 14. Recommended Refrigerant Capacities

Capacity

Total Interconnecting Line Length

50 100 150

Approximate Total System Refrigerant Charge (Lbs. Per Circuit)

20 Ton495664

25 Ton587387

30 Ton718599

40 Ton465361

50 Ton567085

60 Ton688297

Table 15. Minimum starting Ambient Temperature

Minimum Starting Ambient (1)

Standard Units Low Ambient Units