70 SS-SVX09A-EN

System Pre-Start Procedures

Note: It is unlawful to release refrigerant into the atmosphere. When service procedures require

working with refrigerants, the service technician must comply with all Federal, State, and

local laws. Refer to the General Service Bulletin MSCU-SB-1 (latest edition).

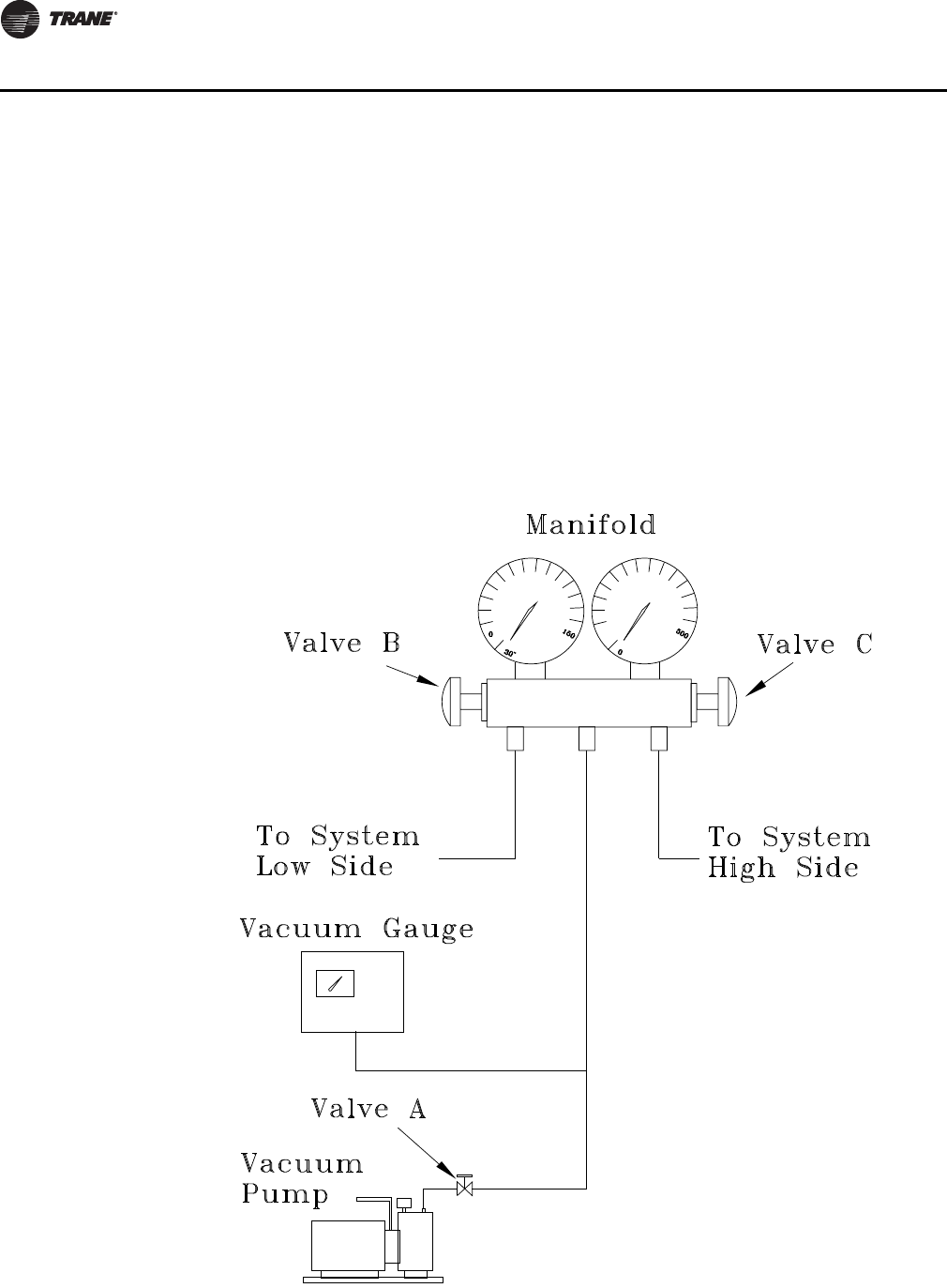

Standing Vacuum Test

Once 300 microns or less is obtained, close Valve A and leave valves B and C open. This will allow

the vacuum gauge to read the actual system pressure. Let the system equalize for approximately

15 minutes. This is referred to as a “standing vacuum test” where, time versus pressure rise. The

maximum allowable rise over a 15 minute period is 200 microns. If the pressure rise is greater than

200 microns but levels off to a constant value, excessive moisture is present. If the pressure steadily

continues to rise, a leak is indicated. Figure 35 illustrates three possible results of the “standing

vacuum test”. If a leak is encounter, repair the system and repeat the evacuation process until the

recommended vacuum is obtained. Once the system has been evacuated, break the vacuum with

refrigerant, and complete the remaining “Pre-Start Procedures” before starting the unit.

Figure 34. Typical Vacuum Pump Hookup