15

Loop Water Applications

It should be noted that there is no me-

chanical difference between geother-

mal (closed loop) and ground water

(open loop) GSSD units. Generally in

a closed loop application, there is a

percentage of antifreeze in the water.

In these applications, the 20 degree F

freezestat, along with the 7 psig safety

pressure switch may be used. All other

applications require the 35 degree F

freezestat, along with the 35 psig safe-

ty pressure switch.

Ground Water Applications

(Open Loop)

Where an existing or proposed well

can provide an ample supply of suit-

able quality water, open ground water

systems may be very efficient. How-

ever, there are several potential con-

siderations that should be addressed

prior to installation of an open loop

system:

! A 60 mesh straining device must

be placed in the incoming water

line. The sand filter/separator

helps ensure clean water by

removing any particles in the

water. Note: A filter/separator

should be available from your

local dealer.

! Even if plenty of water is

available, there needs to be an

acceptable way to discharge it

after it has passed through the heat

pump. A three-ton heat pump is

apt to use one million gallons of

water per year. It may be

necessary to install a recharge well

to return the water to the aquifer.

In some soils, this may be difficult

to do.

! Water quality must also be

acceptable to maintain the

integrity and life of the unit. The

loop fluid must have minimal

suspended solids, and must be

non-corrosive to copper or brass.

See Table 2 for specifications.

Ground Water Applications

(Closed Loop)

Loop sizing should be done by a qual-

ified installer to insure maximized unit

performance.

In areas where the ground water tem-

perature is 66 degrees F or less, the

earth coupling fluid requires at least a

15 percent by volume antifreeze solu-

tion. Using Table 3, calculate the ap-

proximate water volume of the

system. Add one gallon to your total as

an allowance for water in each heat

pump and connection hoses. Check

the earth coupling design for the anti-

freeze percentage required. MORE IS

NOT BETTER-Do no exceed the

amount indicated in the design specifi-

cations.

Use only FULL STRENGTH INHIB-

ITED PROPYLENE GLYCOL OR

METHANOL, not solutions which

have already been diluted.

Note:

The water quality of the fluid loop

should meet the same specifications

as in Table 2.

Table 2: Water Supply Requirements

Scaling

Calcium and

magnesium salts

(total hardness)

Less than 350 ppm

Corrosion

pH 7.5-9.5

Hydrogen Sulfide Less than 1 ppm

Sulfates Less than 25 ppm

Carbon dioxide Less than 75 ppm

Chloride Less than 125 ppm

Total dissolved solids

(TDS)

Less than 1000 ppm

Biological Growth

Iron bacteria Low

Erosion

Suspended Solids Low

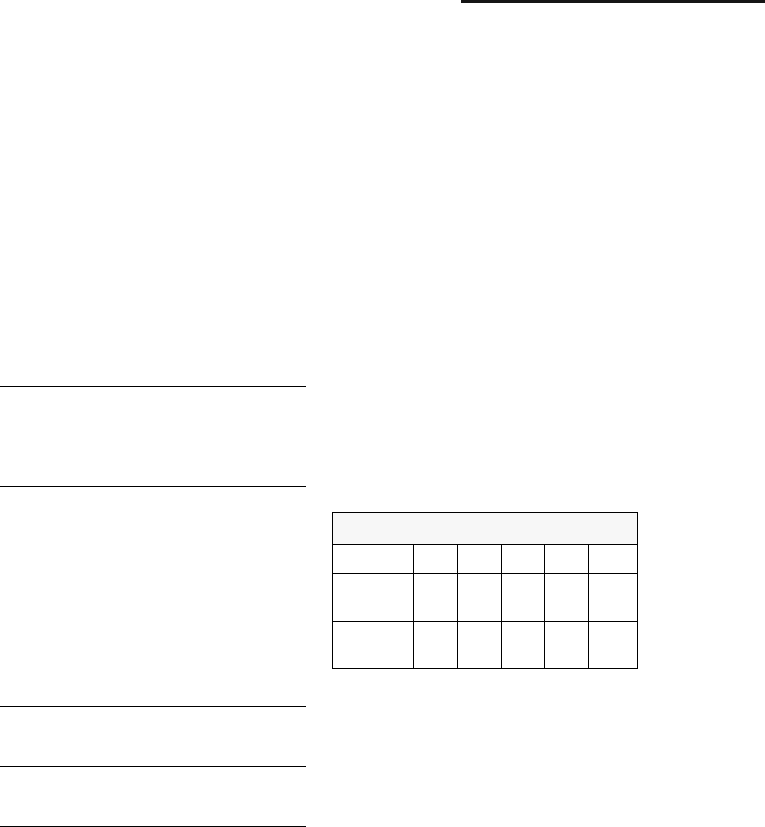

Table 3: Water Volume

Volume in Gallons/100 Ft.

Pipe Size 3/4” 1”

1 1/4” 1 1/2”

2”

Vo lu m e

SDR-11

3.02 4.73 7.52 9.85 15.4

Vo lu m e

SCH 40

2.77 4.49 7.77 10.6 17.4

Installation - Water Loop