Toshiba

–12–

Outdoor Unit

Installation Manual

EN

6 REFRIGERANT PIPING

CAUTION

TAKE NOTE OF THESE 4 IMPORTANT

POINTS BELOW FOR PIPING WORK

1. Keep dust and moisture away from inside the

connecting pipes.

2. Tightly connect the connection between pipes

and the unit.

3. Evacuate the air in the connecting pipes using a

VACUUM PUMP.

4. Check for gas leaks at connected points.

Flaring

1. Cut the pipe with a pipe cutter.

Be sure to remove burrs that may cause a gas leak.

2. Insert the supplied flare nut into the pipe, and then

flare the pipe.

As the flaring sizes of R410A differ from those of

refrigerant R22, the flare tools newly manufactured

for R410A are recommended.

However, the conventional tools

can be used by adjusting the

projection margin of the copper

pipe.

▼ Projection margin in flaring : B (Unit : in (mm))

Rigid (Clutch type)

▼ Flaring diameter size : A (Unit : in (mm))

* In case of flaring for R410A with the

conventional flare tool, pull the tool out

approx. 0.02” (0.5 mm) more than that for

R22 to adjust it to the specified flare size.

The copper pipe gauge is useful for

adjusting the projection margin size.

Tightening of Flare

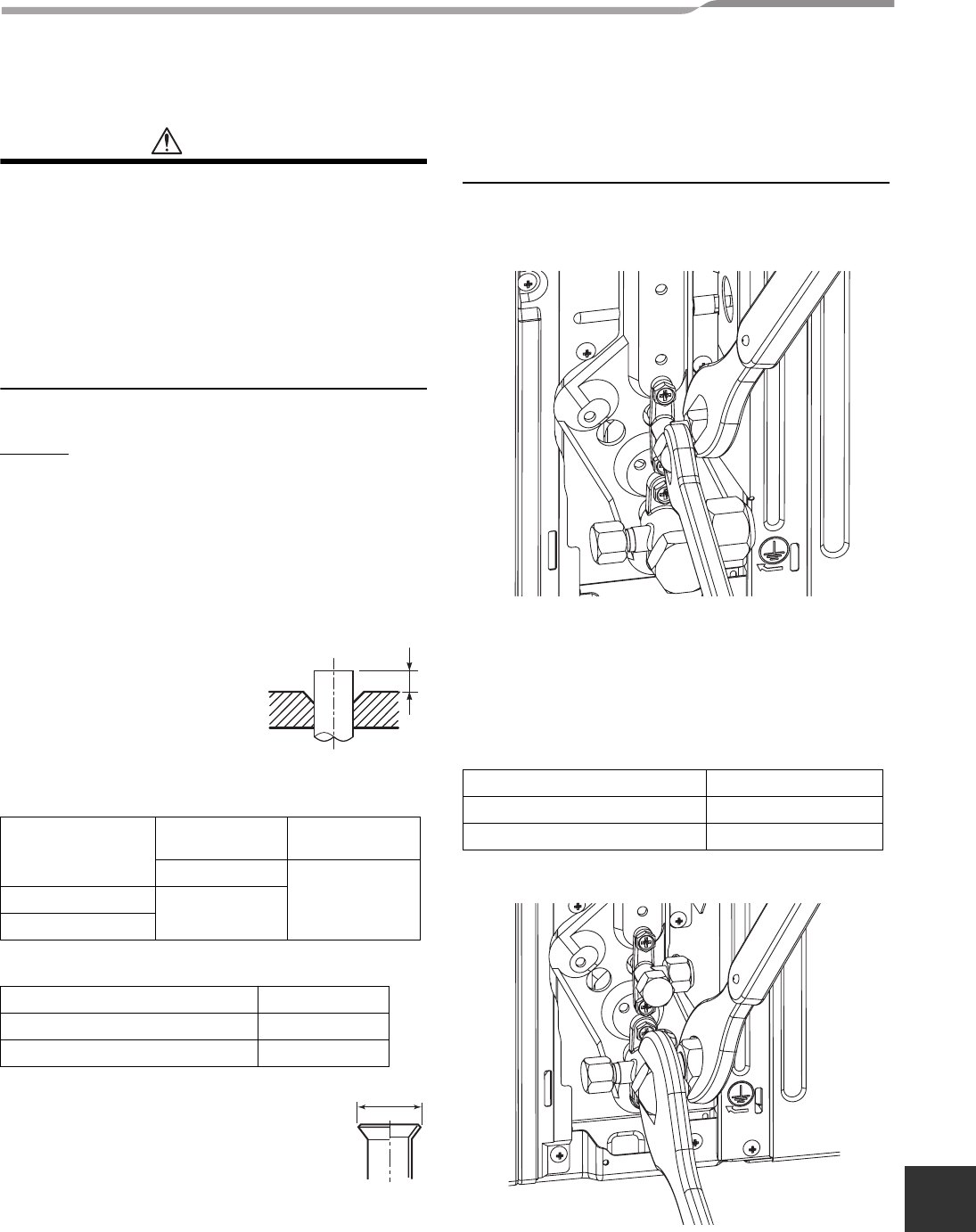

Connections

1. Align the centers of the flare connections and fully

tighten the flare nuts with your fingers.

2. Use two wrenches to loosen or tighten the flare nut

on the gas service valve as shown in the figure.

Use only one wrench to loosen or tighten the flare

not on the liquid service valve.

The final tightening with a torque wrench should be

to the specifications shown in table below.

Unit : ft•lbs (N•m)

Outer diameter of

copper pipe

R410A tool

used

Conventional

tool used

R410A

0.04” - 0.06”

(1.0 - 1.5)

1/4” (6.4)

0 - 0.02” (0 - 0.5)

1/2” (12.7)

Outer diameter of copper pipe A

1/4” (6.4) 0.39” (9.9)

1/2” (12.7) 0.65” (16.6)

B

+0

-0.02" (–0.4)

A

Outer diameter of copper pipe Tightening torque

1/4” (6.4 mm) 10 - 13 (14 - 18)

1/2” (12.7 mm) 37 - 46 (50 - 62)

Valve at liquid side

Valve at gas side

12-EN

+00EH99865301_00Ta.book Page 12 Wednesday, November 25, 2009 11:05 AM