– 54 –

14. Coil heating control

1) This control has the function of heating the compressor by applying a current to the compressor when

not operating instead using a case heater.

This control is for the purpose of preventing stagnation of the refrigerant inside the compressor.

2) Malfunction in the compressor may result if a current is not applied for a specified time before a test run

after installation as was previously the case.

Similarly, starting operation after turning the power OFF and not operating for a long time also requires

application of a current before starting operation, in the same manner as the test run.

3) Application of current is determined by TD and TO sensors.

When the TO sensor is defective, a backup control is automatically performed by the TE sensor.

When TO sensor is defective, make a determination using the LED display of the outdoor interface board.

4) The power is turned off when TD is 30°C or more.

(100W : Total power consumption of inverter and compressor)

NOTE

While heating and electrifying the winding wire, electrifying sound may generate. It is nor abnormal.

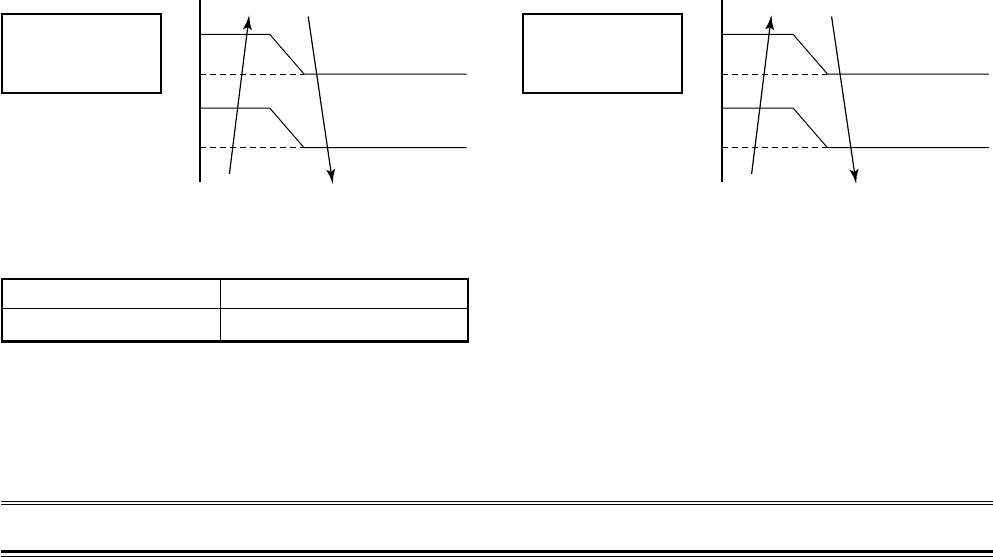

8

10

No current

Intermittent current

ON: 10 minutes

OFF: 5 minutes

Continuous

current

15

18

10

12

18

20

(When TO sensor defective)

TO [˚C] TE [˚C]

No current

Intermittent current

ON: 10 minutes

OFF: 5 minutes

Continuous

current

Current application

conditions

TD < 30˚C

Current application

conditions

TD < 30˚C

Intermittent current

Continuous current

Corresponding to 100w

Corresponding to 100w